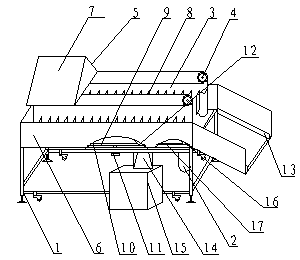

Fish head removing part of automatic production line for fillet processing

A production line and fish fillet technology, applied to fish processing, slicing, slaughtering, etc., can solve the problems of simple function, difficult recruitment, low efficiency, etc., and achieve the effect of solving difficult recruitment, good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] in the attached figure 1 Among them, a head-removing part of an automatic production line for processing fish fillets, which includes a bracket 1 and a motor 2, is characterized in that: the bracket 1 is provided with two conveyor belts 3, and the two conveyor belts 3 are provided with driving wheels 4 and passive wheels at both ends. Wheel 5, the motor 2 is connected with the driving wheel 4, the bracket 1 on the outside of the two conveyor belts 3 is provided with a baffle plate 6, and a fish head and tail identifier 7 is provided above the two conveyor belts 3 at one end of the bracket 1 . Described two conveyer belts 3 are vertically installed on the described support 1, described two conveyer belts 3 two ends are provided with driving wheel 4 and driven wheel 5 respectively to be provided with conveyer belt tray 16, between two conveyer belt trays 16 A conveyor belt pallet 17 is provided. The two conveyor belts 3 are provided with partitions 8 . The inner lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com