Bionic flapping koji-making device and koji-making method thereof

A koji-making device and bionic technology, applied in the field of liquor brewing, can solve the problems of poor extracting effect, high labor intensity, low efficiency, etc., achieve the effect of solving inconsistent strength, high degree of automation, and ensuring fermentation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

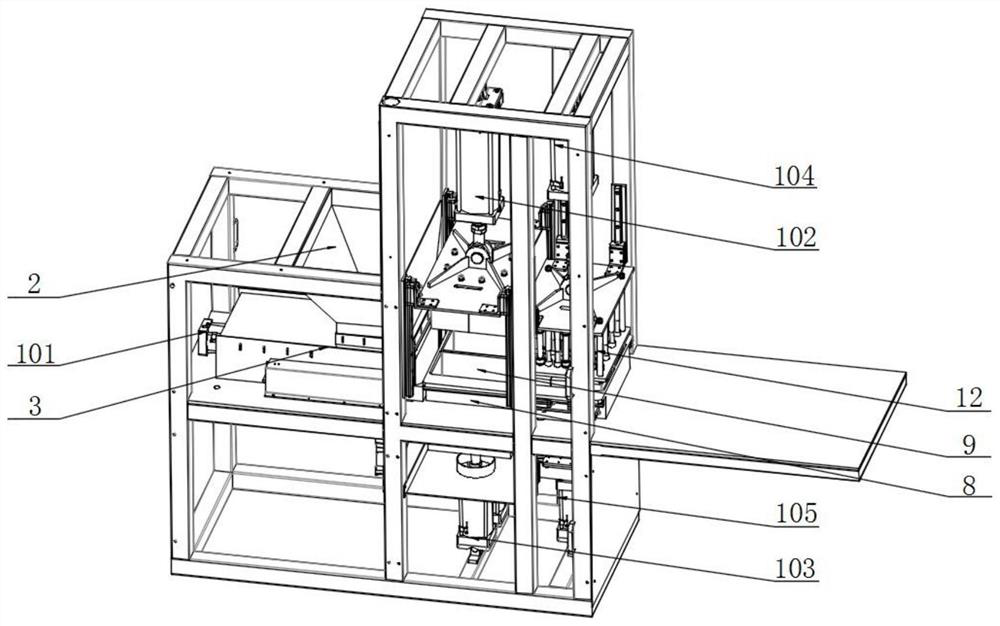

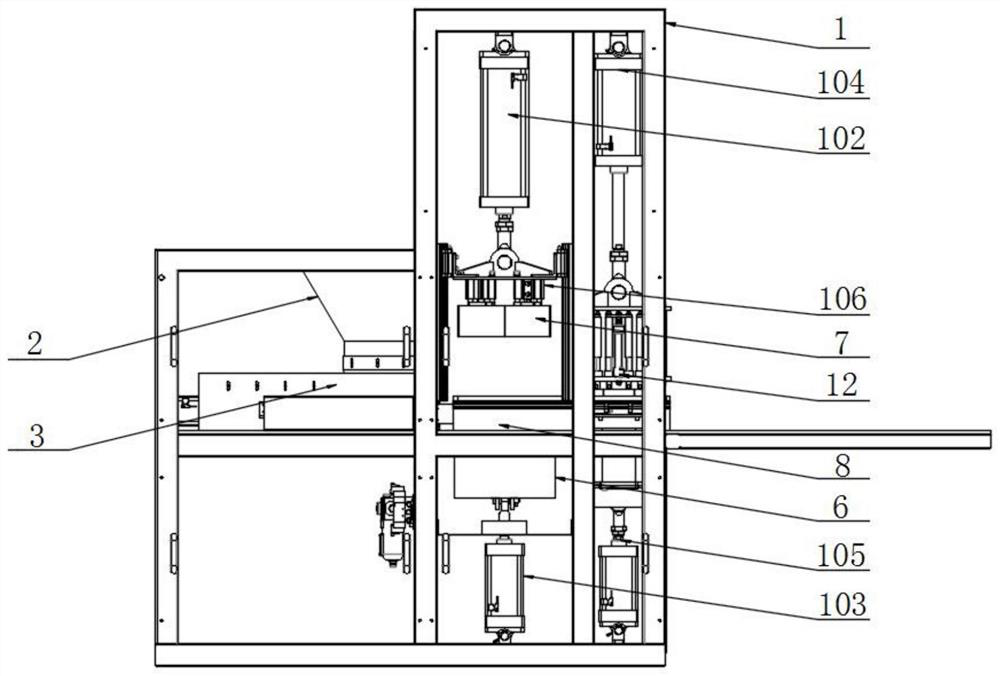

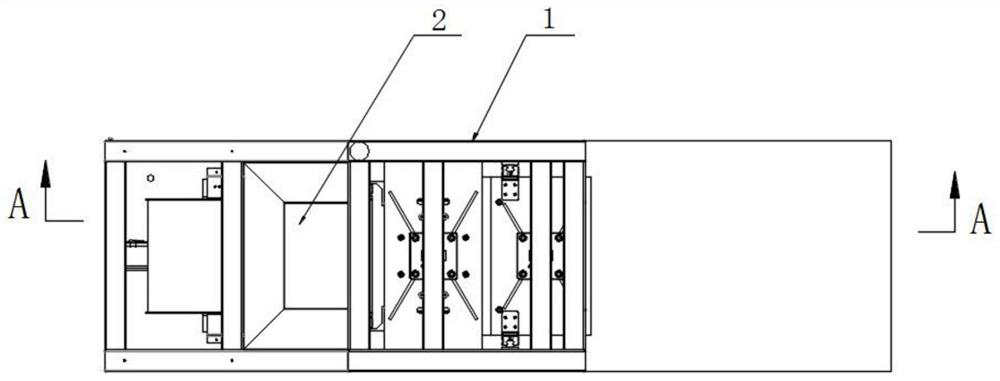

[0054] refer to figure 1 , figure 2 , image 3 with Figure 4 , the bionic beating koji making device of the present invention comprises a frame 1, a hopper 2, a feeding frame 3, a first power mechanism 101, a pre-pressing mechanism and a beating mechanism, and the hopper 2 is arranged on the frame 1; the feeding frame 3 Arranged on the frame 1 below the receiving hopper 2, it is closely matched with the receiving hopper 2, the top of the feeding frame 3 is provided with a feeding port matching the size of the receiving hopper 2, and the bottom of the feeding frame 3 is provided with a discharge port, The bottom of the feeding frame 3 is provided with a mounting plate 4, the mounting plate 4 is fixedly connected to the frame 1, and the feeding frame 3 is slidingly connected to the mounting plate 4; the first power mechanism 101 is arranged on the frame 1 on one side of the feeding frame 3 on, used to drive the feeding frame 3 to reciprocate in the horizontal direction; the...

Embodiment 2

[0064] refer to figure 2 with Figure 4 , the pre-compression module of this embodiment is spliced by at least two die heads 7, the top of the die head 7 is connected with the second power mechanism 102 through the sixth power mechanism 106, and the adjacent die heads 7 are alternately raised and lowered . The inventor of the present application initially designed the pre-compression module as a monolithic structure, and found in actual use that: due to the lack of an exhaust device, the concave pre-compression module needs a lot of pressure to be exhausted in the process of pressing down. The air in its inner cavity requires a large pressure value and has high requirements on the equipment; moreover, during the lifting process of the pre-pressing module, the inner cavity of the flapping module will form a negative pressure, and the negative pressure will be reversed during the lifting process. An upward pulling force is generated on the curved block, which will cause the...

Embodiment 3

[0067] The koji making method is used for the bionic pat koji making device of embodiment two, comprising the following steps:

[0068] S1 Feed input: The material enters the feeding frame 3 through the receiving hopper 2 for quantification, the material is piled up in the feeding frame 3, the first power mechanism 101 drives the feeding frame 3 to move to the pre-pressing mechanism, and the material in the feeding frame 3 Fall into the pre-compression mold box 6 through the discharge port;

[0069] S2 pre-compression forming: the second power mechanism 102 drives the pre-compression module to descend, and the sixth power mechanism 106 drives the die head 7 to reciprocate up and down to press the loose material in the pre-compression mold box 6 into a curved block; the second power mechanism 102 then Drive the pre-pressing module to rise and reset; the third power mechanism 103 drives the curved block in the pre-pressing mold box 6 to rise into the through groove 9 of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com