Ceramic dust suction-blowing integrated machine

An all-in-one machine and ash-blowing technology, which is applied in the field of ceramic machinery and ceramic ash-absorbing and soot-blowing all-in-one machines, can solve problems such as high labor intensity, great damage to human health, and poor working environment, so as to reduce labor intensity, solve recruitment difficulties, and avoid diffuse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

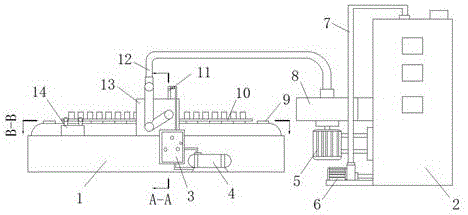

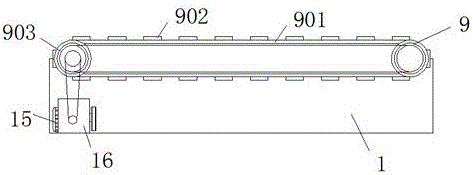

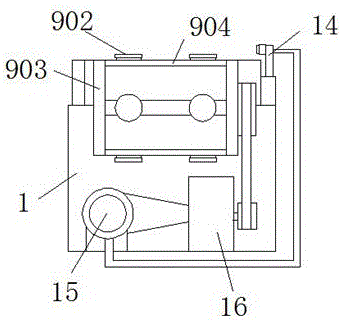

[0021] Such as Figure 1-5 As shown, a ceramic soot suction and blowing integrated machine includes a workbench 1 and a dust removal box 2. The upper middle part of the workbench 1 is fixed with a dust collection cover 13, and the middle part of the front side of the workbench 1 is fixed with a control box 3. , the right side of the control box 3 is provided with an air pump 4, and the induction switch 14 is fixed on the left side of the dust collection cover 13 on the workbench 1, and two are arranged at the same height, and the workbench 1 is provided with Conveyor 9, the dust suction cover 13 is straddled on the conveyor 9, the blank plate 10 is arranged on the conveyor 9, the cup blank is placed on the blank plate 10, and the dust suction cover 13 is provided with a dust collector Pipe 12, the lower end of the dust suction pipe 12 is sealed and fixedly connected to both sides of the dust collection hood 13, the upper surface of the dust collection hood 13 is located on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com