Board pushing system of multi-layer hot press

A multi-layer hot press and multi-layer board technology, which is applied in the field of board processing, can solve the problems of difficult recruitment, low production efficiency, and high labor intensity in enterprises, so as to reduce the interference of human factors, solve the problem of difficult recruitment, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

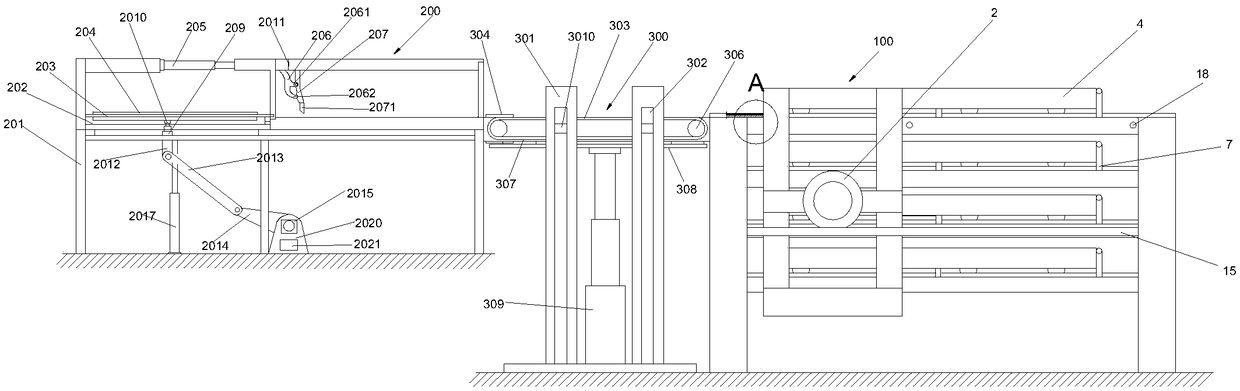

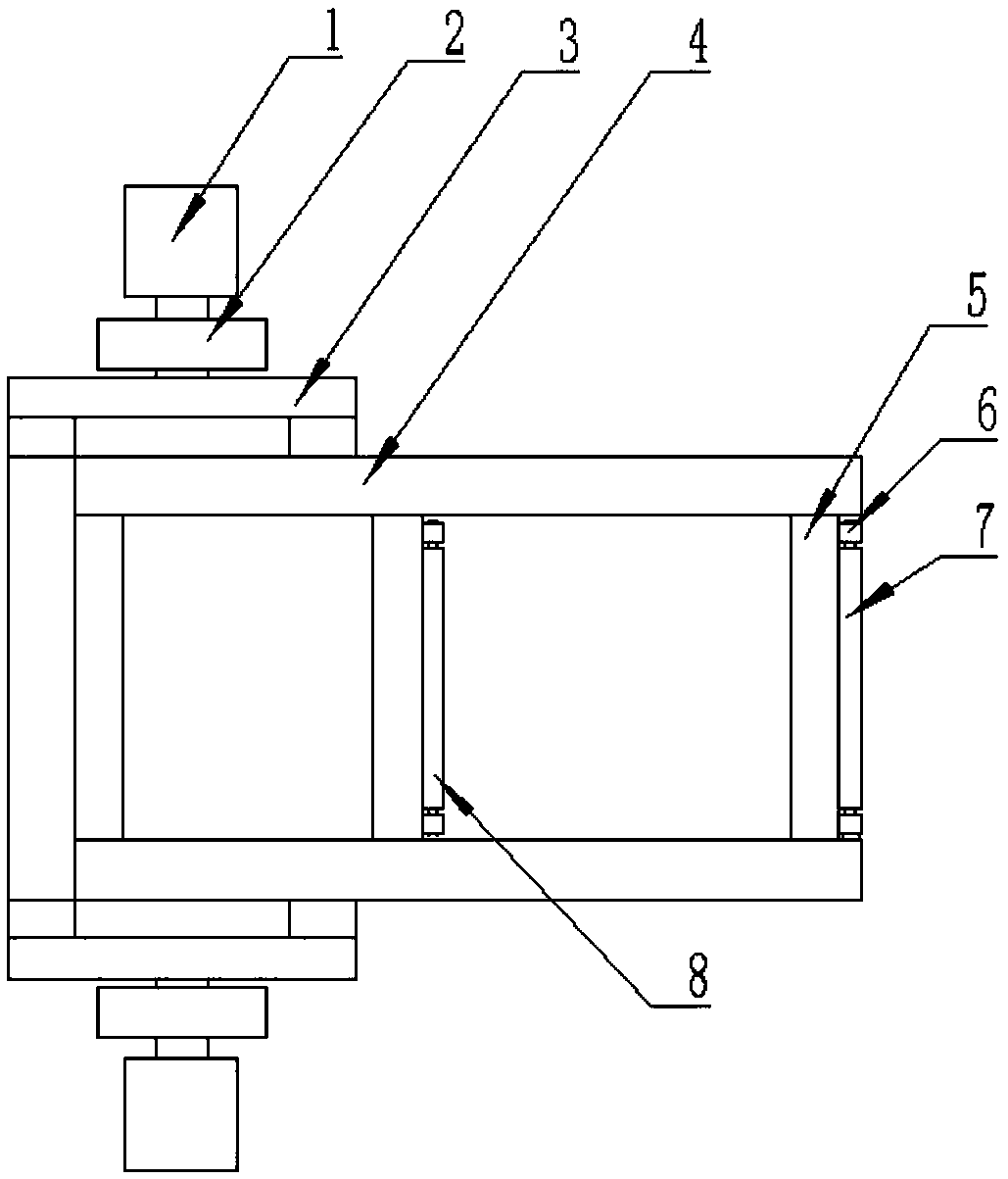

[0044]like Figure 1 to Figure 4 As shown, the plate pushing system of the multilayer hot press according to the present invention includes a plate pushing device 200, a feeding device 300 and a multilayer plate conveying device 100;

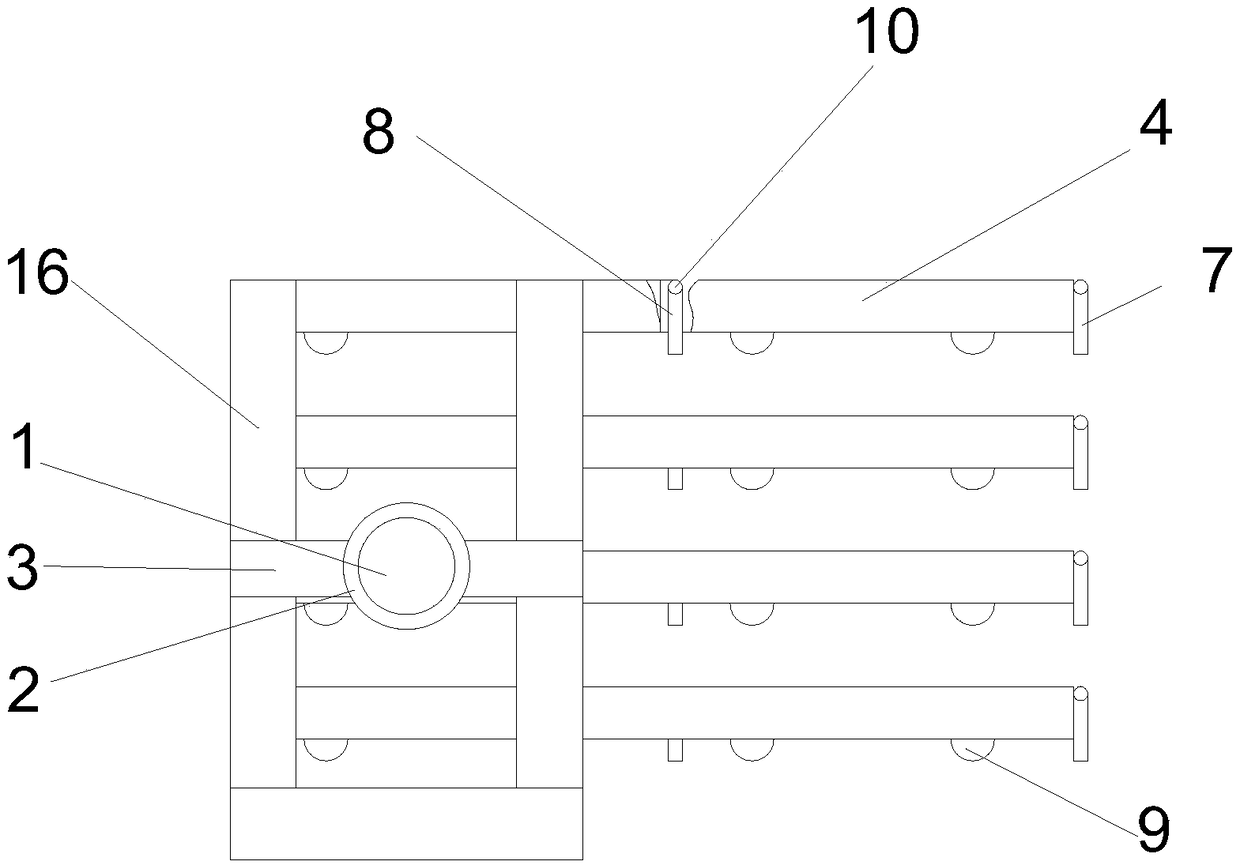

[0045] The multi-layer sheet material conveying device 100 includes a support platform and a walking mechanism; the support platform includes at least two layers of horizontal support beams 13; the two ends of the horizontal support beams 13 are provided with support legs 14; and each layer of horizontal support beams 13 A plate support plate 12 is arranged on the top; a guide rail 11 is provided on the plate support plate 12; a horizontal walking rack 15 is provided between the support legs 14 at both ends of the horizontal support beam 13;

[0046] Described traveling mechanism comprises at least two layers of walking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com