Laser-based large-area glass plate local convex-concave defect detection method

A defect detection and glass plate technology, used in optical testing flaws/defects, measuring devices, scattering characteristics measurement, etc., can solve problems such as unaffordable, expensive, and narrow detection widths of enterprises, and solve the problem of yield and manpower. High cost and the effect of solving recruitment difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

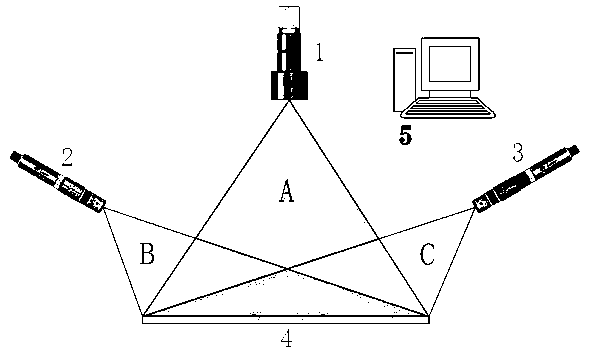

[0038] Example 1 Convex defect detection:

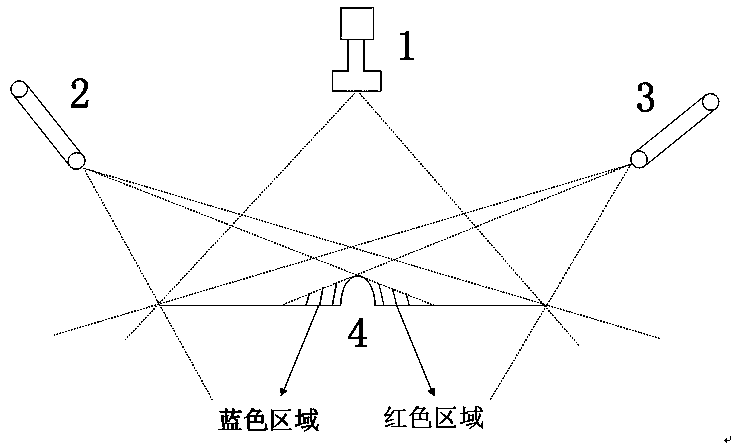

[0039] The 405nm low-angle laser on the left is irradiated on the local convex defect, and there will be a large reflection of light on the side of the convex position facing the left 405nm laser, and a bright blue light spot will appear in the imaging of the color line scan camera. There are no large reflections on the side facing away from the left 405nm laser.

[0040] At the same time, when the right low-angle 655nm laser is irradiated on the same local convex defect, a large amount of light will be reflected on the side of the convex position facing the right 655nm laser, and a bright red light spot will appear in the imaging of the color line scan camera. No large reflections occur on the side facing away from the laser on the right.

[0041] In the imaging of the color line scan camera, the two lasers emit light at the same time, so a pair of light spots appear on the local convex defect image, the left side is blue, and the ...

Embodiment 2

[0043] Embodiment 2 local concave defect detection:

[0044] The 405nm low-angle laser on the left is irradiated on the local convex defect, and there will be a large reflection of light on the side of the convex position facing the left 405nm laser, and a bright blue light spot will appear in the imaging of the color line scan camera. There are no large reflections on the side facing away from the left 405nm laser.

[0045] When the low-angle 655nm laser on the right is irradiated on the same local convex defect, a large amount of light will be reflected on the side of the convex position facing the right 655nm laser, and a bright red light spot will appear in the imaging of the color line scan camera. No large reflections occur on the side facing away from the laser on the right.

[0046] In the imaging of the color line scan camera, the two lasers emit light at the same time, so a pair of light spots appear on the local convex defect image, the left side is blue, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com