Large-diameter steel pipe double welding torch intelligent welding equipment

A technology of welding equipment and double welding torches, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing labor costs of construction enterprises, difficulty for electric welders, large size and inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

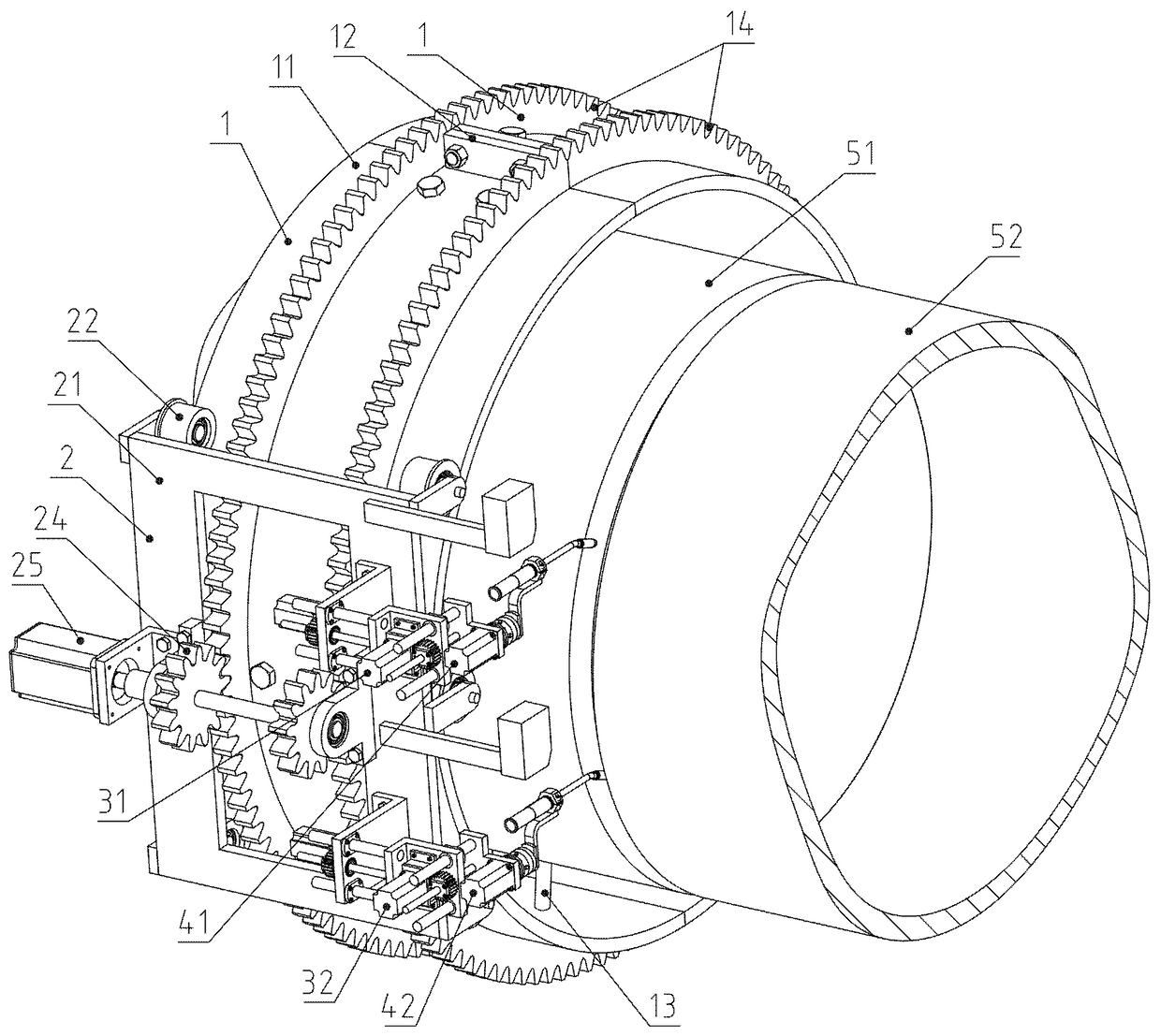

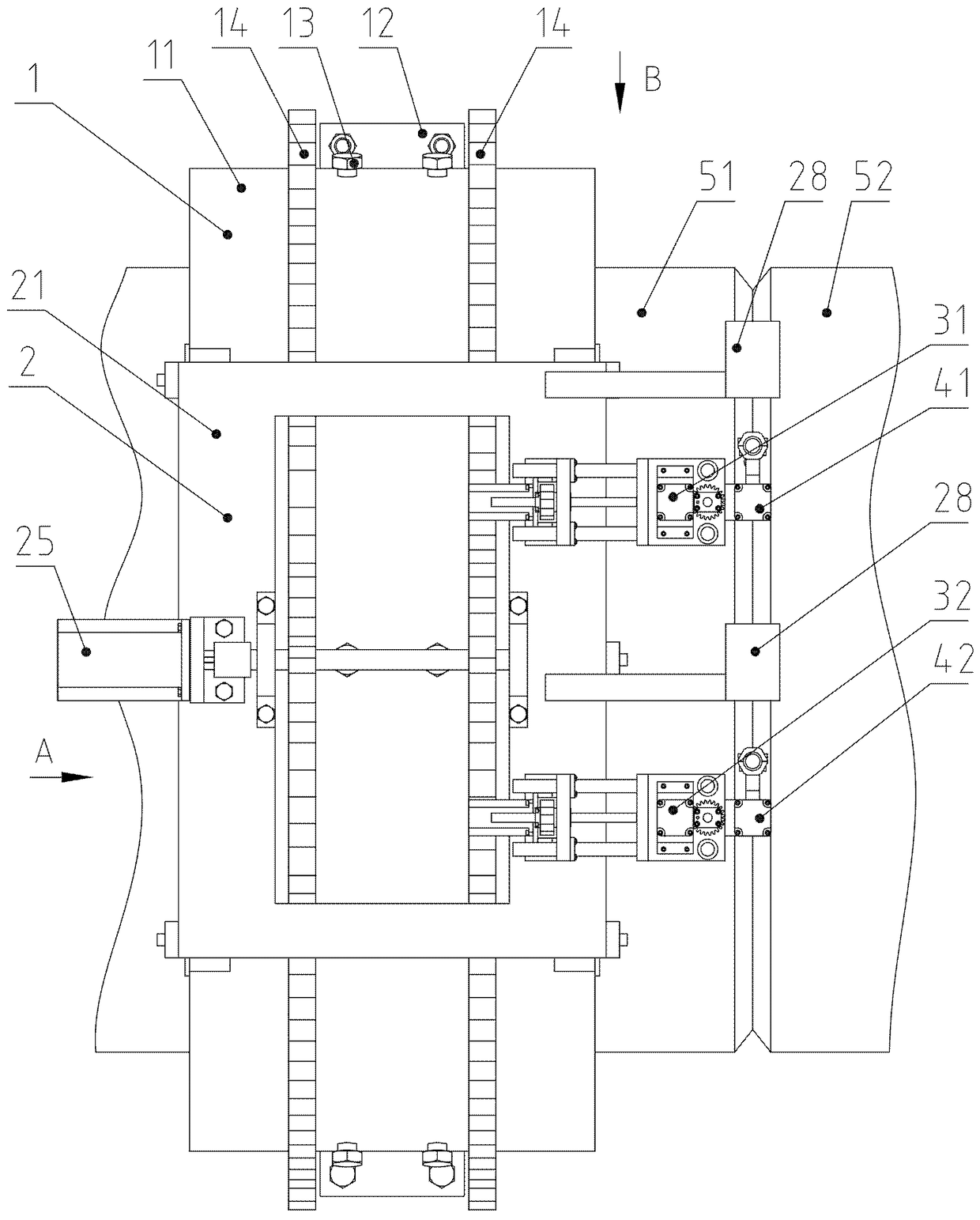

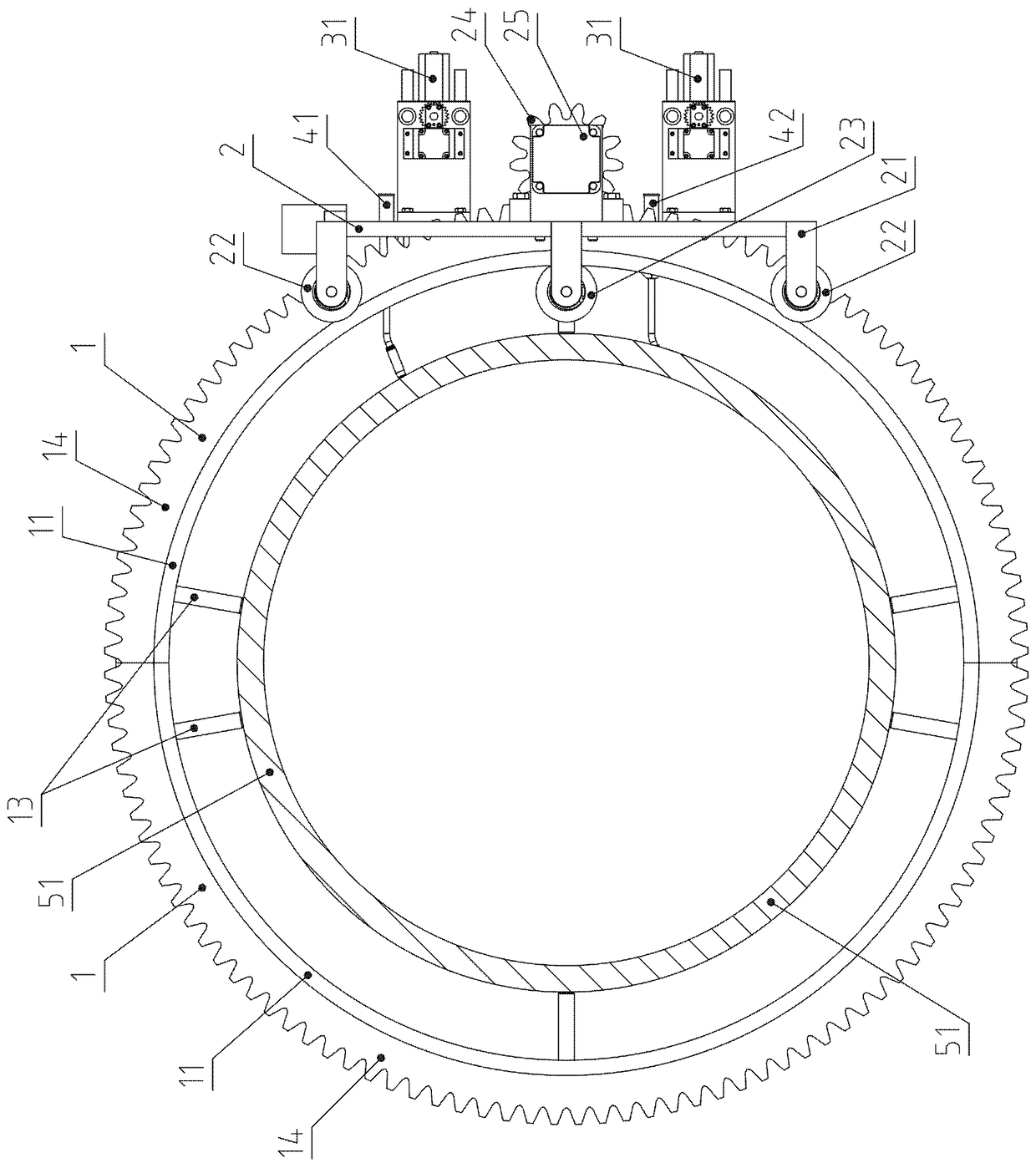

[0052] Embodiment 1: see Figure 1 to Figure 12 .

[0053] An intelligent welding device with double welding torches for large-diameter steel pipes, including a circular ring assembly, a circular trolley 2, an axial moving part I 31, an axial moving part II 32, a radial moving part I 41 and a radial moving part II 42;

[0054] A ring assembly includes two half ring assemblies 1, and a half ring assembly 1 includes a half ring 11, a flange plate 12, support bolts 13 and two half ring gears 14, and the outer arc surface of the half ring 11 Fitted with the inner arc surface of the half ring gear 14, the two are fixedly connected with the axis line, and the end faces parallel to the axis line direction are aligned; the flange plate 12 is fixed on the half ring 11 parallel to the axis line direction On the end face: the two pairs of end faces parallel to the axial direction of the two semi-circular ring components 1 are respectively fitted together and the adjacent flange plates 12 ...

Embodiment 2

[0077] Example 2: see Figure 13 , is the situation of the welding intersecting curve of the intelligent welding equipment with double welding torches for large-diameter steel pipes. The large-diameter steel pipe I 51 and the large-diameter steel pipe III 53 vertically intersect and run through, and the intersection line is the intersecting line. Diameter steel pipe I 51 moves in a circular direction under the action of ring motor 25, moves parallel to the axis of large diameter steel pipe I 51 under the action of axial motor I 265, and moves in a direction parallel to the axis of large diameter steel pipe I 51 under the action of radial motor I 314. Next, move along the radial direction of the large-diameter steel pipe I 51, combined with the action of the swing motor I 414, the four motors coordinate their actions, and the welding torch I 417 can complete the welding of the weld near the circular trolley 2. Because it is difficult to coordinate the simultaneous work of two w...

Embodiment 3

[0078] Embodiment 3: see Figure 14 , is the situation of the welding intersecting curve of the large-diameter steel pipe double-welding torch intelligent welding equipment, the large-diameter steel pipe I 51 and the small-diameter pipe joint 54 vertically intersect and run through, and the intersection line is an intersecting line. The steel pipe I 51 moves in a circular direction under the action of the ring motor 25, moves parallel to the axis of the large-diameter steel pipe I 51 under the action of the axial motor I 265, and moves in the direction of the axis of the large-diameter steel pipe I 51 under the action of the radial motor I 314. Do the motion along the radial direction of the large-diameter steel pipe I 51, combined with the effect of the swing motor I 414, the welding torch I 417 can complete the welding of the weld around the small-diameter pipe joint 54 one week. Welding torch II 427 is idle. Other structures, functions and beneficial effects are the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com