Modified fibre enhanced foaming cement composite floor and preparation method thereof

A technology of modified fiber and foamed cement, which is applied in the field of building materials, can solve the problems of all-light concrete due to the variation of lightweight aggregate properties, the high cost of reinforced composite wood flooring, and the difficulty in quality monitoring, so as to improve building utilization efficiency and construction efficiency. Fast, low energy consumption in production and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

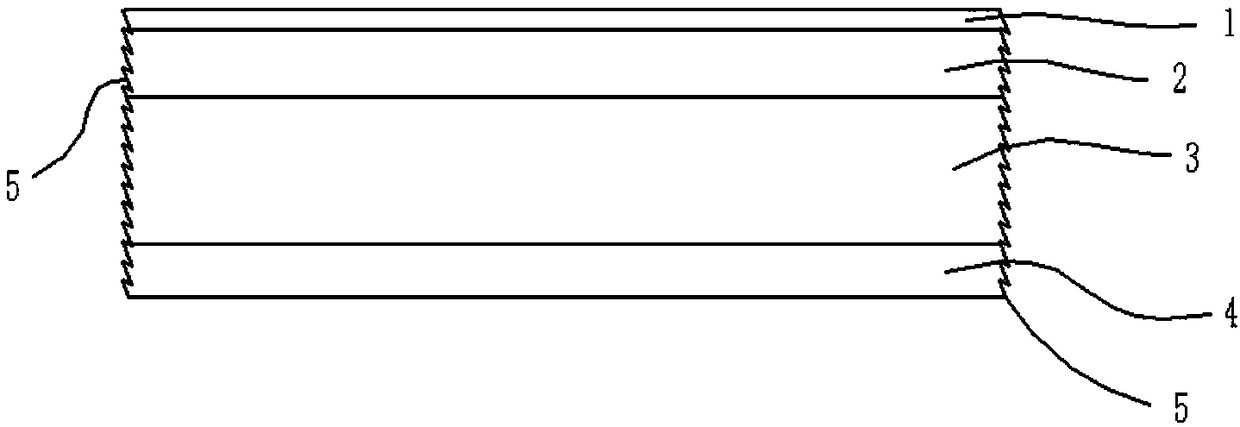

[0044] Embodiment 1: as figure 1 , figure 2 The modified fiber-reinforced foamed cement composite floor shown mainly includes a wear-resistant layer 1, a decorative layer 2, an insulation layer 3, an interface connection layer 4 and a connection notch 5; the decorative layer 2 is a wood grain layer printed on base paper , the decorative layer 2 is arranged under the wear-resistant layer 1, the heat-insulation layer 3 is arranged under the decoration layer 2, the interface connection layer 4 is arranged under the heat-insulation layer 3; the connection notch 5 is arranged on the wear-resistant layer 1, the decoration layer 2 , the side ports of the insulation layer 3 and the interface connection layer 4;

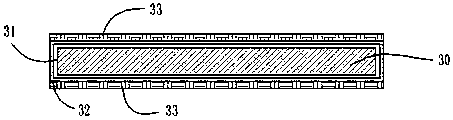

[0045] The thermal insulation layer 3 includes a thermal insulation board 30, an alkali-resistant sealing layer 31, a glass fiber mesh cloth 32 and a low-alkalinity anti-cracking glue layer 33; the thermal insulation board 30 is a cuboid, and the alkali-resistant sealing la...

Embodiment 2

[0064] Embodiment 2: Different from Embodiment 1: insulation board 30 is made of 110 parts of Portland cement, 113 parts of calcium stearate, 6 parts of modified fiber, 10 parts of gypsum, 1.2 parts of diphenylamine-4-sodium sulfonate , prepared by mixing 1 part of alkylphenol polyoxyethylene ether, 10 parts of additives for foamed cement insulation boards, 3 parts of water reducing agent, 6 parts of coupling agent, 7 parts of foaming agent, and 65 parts of water; The modified fiber is mixed with 30 parts of carboxymethyl cellulose, 9 parts of polyamide, 13 parts of cellulose acetate, 12 parts of acrylate, 13 parts of graphene oxide, and 25 parts of diethylene glycol diacrylate before heating After stirring evenly, mix it with ionized water at a mass ratio of 1:15; then ultrasonically disperse and beat to obtain a mixed solution; centrifuge, dry, and grind; the low-alkalinity anti-cracking mortar is made of 12 parts of phosphate cement , 16 parts of sodium chloride and / or calc...

Embodiment 3

[0081] Embodiment 3: Different from Embodiment 1: insulation board 30 is made of 120 parts of Portland cement, 20 parts of calcium stearate, 8 parts of modified fiber, 20 parts of gypsum, 1.6 parts of diphenylamine-4-sodium sulfonate , 2 parts of alkylphenol polyoxyethylene ether, 12 parts of additives for foamed cement insulation boards, 5 parts of water reducing agent, 8 parts of coupling agent, 10 parts of foaming agent, and 80 parts of water are mixed and prepared; The modified fiber is mixed with 50 parts of carboxymethyl cellulose, 10 parts of polyamide, 15 parts of cellulose acetate, 15 parts of acrylate, 20 parts of graphene oxide, and 60 parts of diethylene glycol diacrylate before heating After stirring evenly, mix it with ionized water at a mass ratio of 1:15; then ultrasonically disperse and beat to obtain a mixed solution; centrifuge, dry, and grind; the low-alkalinity anti-cracking mortar is made of 15 parts of phosphate cement , 25 parts of sodium chloride and / o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com