Novel hydraulic wear-resisting sealing ring and machining process

A processing technology and sealing ring technology, which is applied in the field of new hydraulic wear-resistant sealing rings and processing technology, can solve the problems of employees and the environment, occupational hazards, etc., and achieve the effect of eliminating hazards and occupational hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

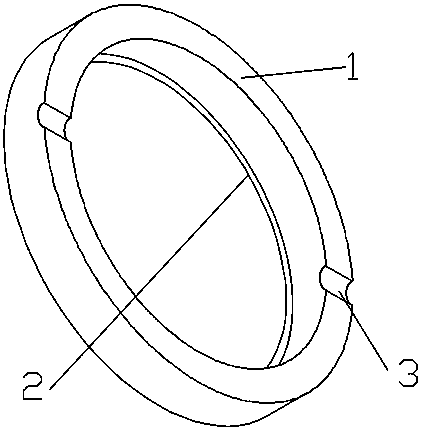

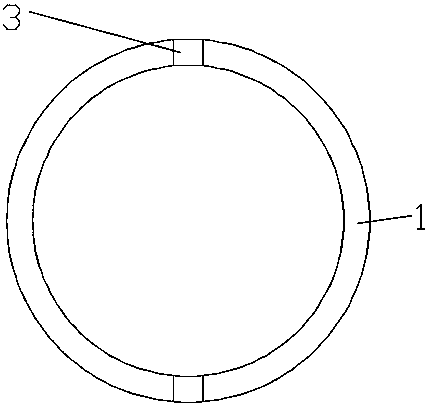

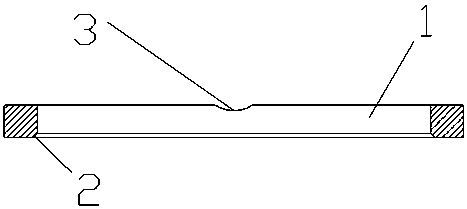

[0034] A new wear-resistant seal ring for hydraulic pressure, including a seal ring main body 1, a groove 2 and an oil discharge groove 3, a groove 2 is opened on one side edge of the inner diameter of the seal ring main body 1, and the seal ring main body 1 is opposite to the groove 2 Correspondingly, there is an oil unloading groove 3 on the other side.

[0035] A processing technology for a novel wear-resistant seal ring for hydraulic pressure, comprising the following steps: Step 1, raw material selection; Step 2, raw material mixing; Step 3, injection molding; Step 4, turning processing; Step 5, inspection and packaging;

[0036] Wherein in the above-mentioned step one, according to the weight percentage of each component is respectively: 100 parts of modified TPU, 3 parts of tackifier, 3 parts of layered silicate powder, 3 parts of release agent and 3 copies of color masterbatch for selection;

[0037] Wherein in the above step 2, all the raw materials are sequentially ...

Embodiment 2

[0049] A new wear-resistant sealing ring for hydraulic pressure, including a sealing ring main body 1, a groove 2 and an oil discharge groove 3, a groove 2 is opened on the inner diameter side edge of the sealing ring main body 1, and the sealing ring main body 1 is opposite to the groove 2 The other side of the corresponding opening is provided with unloading groove 3.

[0050] A processing technology for a novel wear-resistant sealing ring for hydraulic pressure, comprising the following steps: Step 1, raw material selection; Step 2, raw material mixing; Step 3, injection molding; Step 4, turning processing; Step 5, inspection and packaging;

[0051] Wherein in the above-mentioned step one, according to the weight percentage of each component is respectively: 125 parts of modified TPU, 3 parts of tackifier, 3 parts of layered silicate powder, 3 parts of release agent and 3 parts of color masterbatch are selected;

[0052] Wherein in the above step 2, all the raw materials a...

Embodiment 3

[0064] A new wear-resistant seal ring for hydraulic pressure, including a seal ring main body 1, a groove 2 and an oil discharge groove 3, a groove 2 is opened on one side edge of the inner diameter of the seal ring main body 1, and the seal ring main body 1 is opposite to the groove 2 Correspondingly, there is an oil unloading groove 3 on the other side.

[0065] A processing technology for a novel wear-resistant seal ring for hydraulic pressure, comprising the following steps: Step 1, raw material selection; Step 2, raw material mixing; Step 3, injection molding; Step 4, turning processing; Step 5, inspection and packaging;

[0066] Wherein in the above-mentioned step one, according to the weight percentage of each component is respectively: 150 parts of modified TPU, 3 parts of tackifier, 3 parts of layered silicate powder, 3 parts of release agent and 3 copies of color masterbatch for selection;

[0067] Wherein in the above step 2, all the raw materials are sequentially ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com