Surface-to-air-missile-type red lead energy-saving oxidizing furnace

An oxidation furnace and a technology of an oxidation furnace, applied in the field of oxidation furnaces, can solve the problems of large maintenance shutdown losses, energy consumption, and long three-stage oxidation time, and achieve the effects of improving production efficiency, avoiding environmental pollution, and avoiding occupational hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

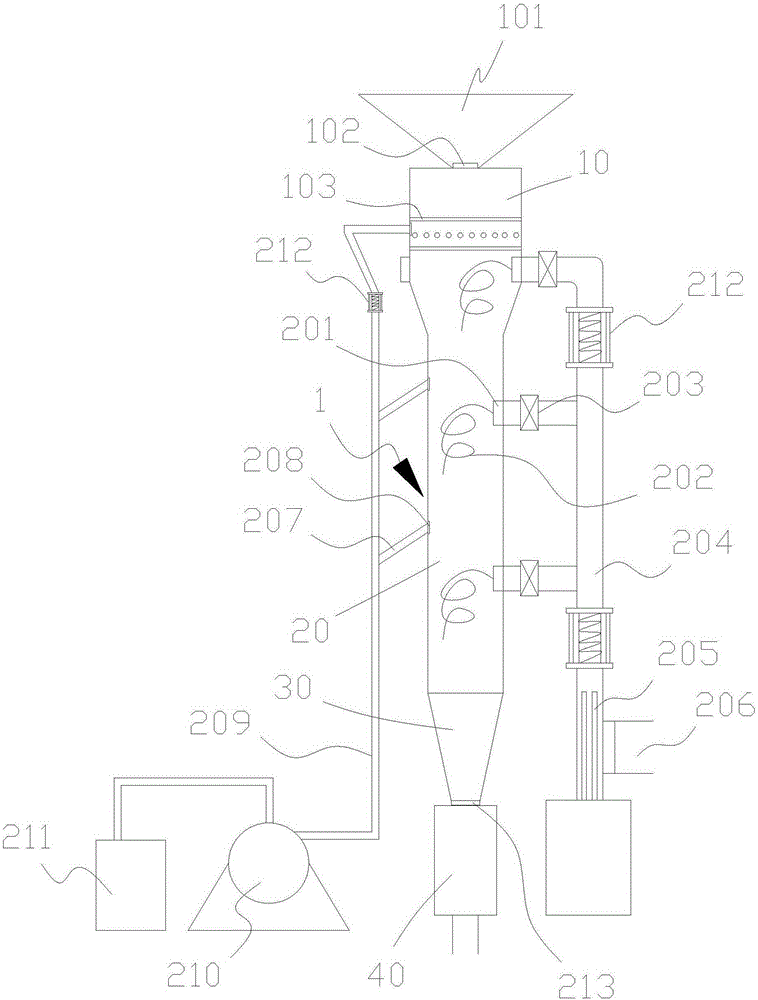

[0017] see figure 1 : a surface-to-air missile type red lead energy-saving oxidation furnace, comprising an oxidation furnace body 1, the oxidation furnace body 1 is a cylindrical structure, and the oxidation furnace body 1 is divided into an upper furnace body 10 and an intermediate furnace body 20 from top to bottom And lower body of furnace 30; Oxidation furnace body 1 exterior uses aluminum silicate fiber felt to wrap around, in order to reach the effect of heat preservation and sound insulation, and uses four-legged support to fix.

[0018] The upper furnace body 10 accounts for about 1 / 5 of the length of the oxidation furnace body 1, and the caliber is slightly thicker than that of the lower part (the size of the caliber can be determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com