Grenade powder surface finishing equipment

A grenade, drug surface technology, applied in the direction of ammunition, offensive equipment, weapon accessories, etc., can solve the problems of high risk, poor operating environment, low intrinsic safety, etc., to achieve a high degree of automation, reduced risk, and avoid unsafe hidden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

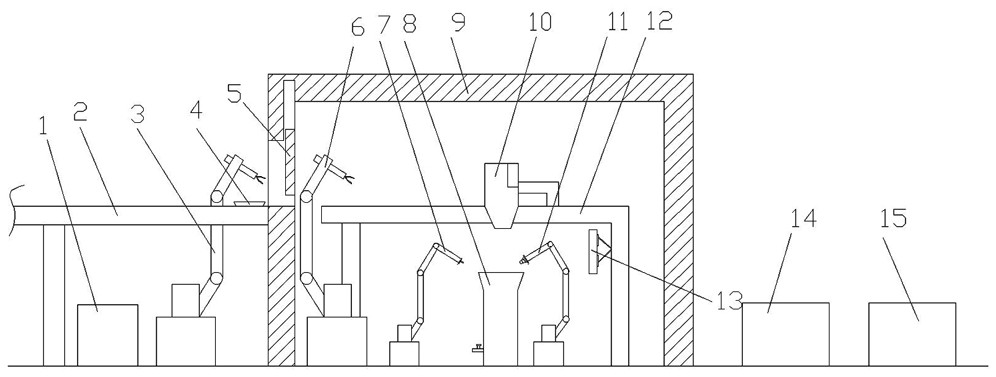

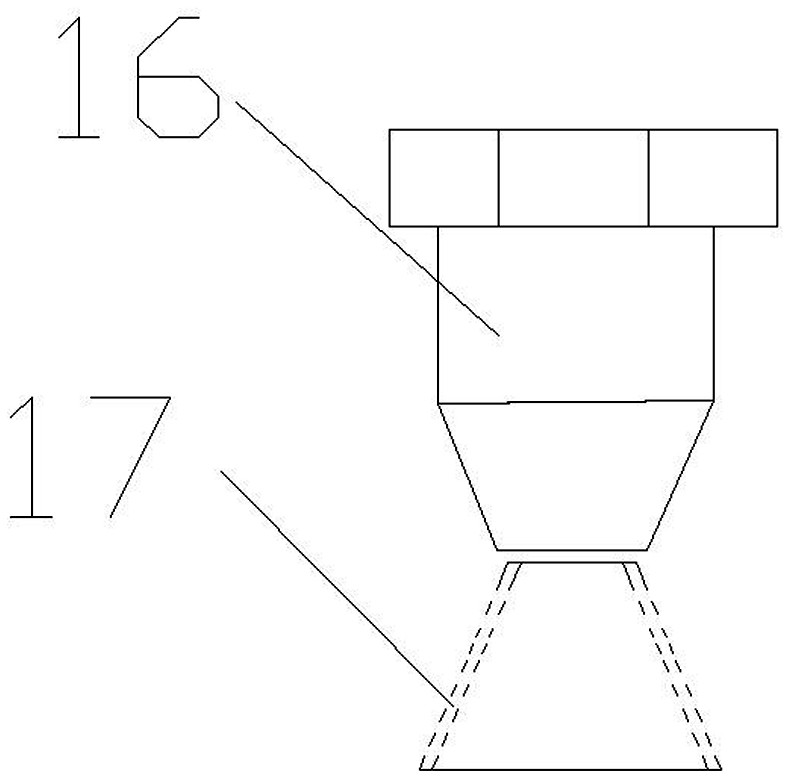

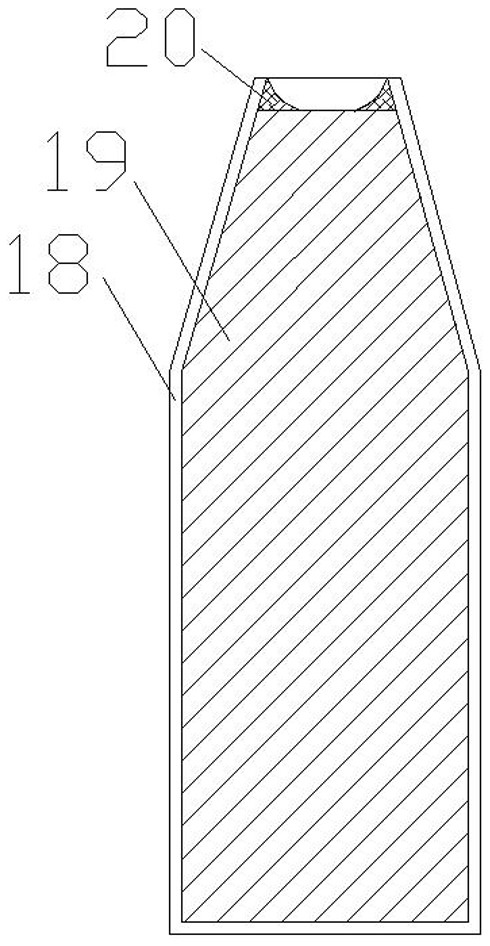

[0021] attached Figure 1-2 It is an embodiment of the present invention, which discloses a grenade ammunition surface trimming device, including an anti-blast chamber 9, a conveying device and a trimming device; one side of the anti-blast chamber 9 is provided with an anti-blast window 5 for transferring grenades , the anti-blast window 5 can be automatically closed and opened during the working process; the conveying device is arranged near the outside of the anti-blast window 5, including a conveyor belt 2 and a tray 4 arranged on the surface of the conveyor belt 2 for placing grenades, One side of the conveying device is provided with a transfer manipulator 3; the trimming device is located inside the anti-blast chamber 9, and includes a turning manipulator 6 near the inside of the anti-blast window 9 and a workbench 12 arranged near the turning manipulator 6. The manipulator 6 is used to receive and turn over the grenade from the transfer manipulator 3. A projectile bin 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com