Chemical poison occupational hazard risk grade evaluation method for petrochemical enterprises

A technology of risk level and occupational hazard, applied in the field of level assessment, can solve the problems of inapplicable occupational hazard risk assessment of petrochemical enterprises, index division is not suitable for petrochemical enterprises, etc., and achieve the effect of reducing enterprise cost and improving management efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

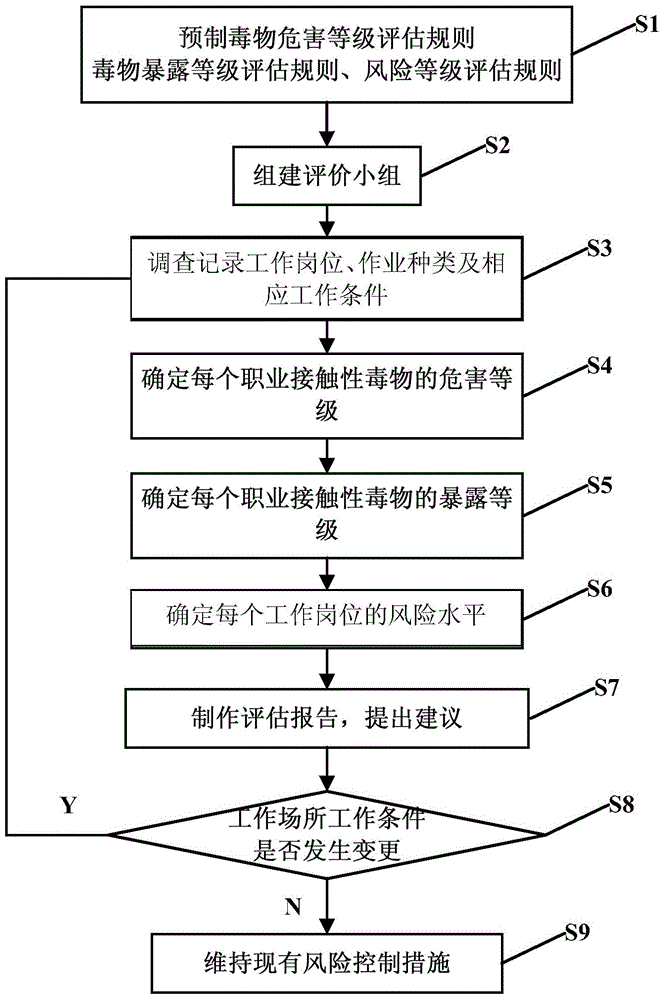

Method used

Image

Examples

Embodiment 1

[0080] Take the delayed coking unit of a refinery as an example: the delayed coking unit includes coking system, fractionation system, steam blowing and venting system, hydraulic decoking system, coke cutting water and coke cooling water system.

[0081] S3: Detect and record the types of operations in the workplace: outside operators, decoking workers, high-pressure water pump workers and maintenance workers.

[0082] The work of the outside operator includes patrol inspection and acid gas sampling, the work content of the decoking worker is decoking, the work content of the high-pressure water pump worker is oil and sewage irrigation switching, and the work of the inspection and maintenance worker is cleaning the coke of the vent tower and venting the filter at the bottom of the tower Dismantling and washing and cleaning of the burner nozzle of the heating furnace.

[0083] The main sanitation engineering measures adopted include automation of production equipment, airtight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com