Patents

Literature

41results about How to "The working environment is clean and tidy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

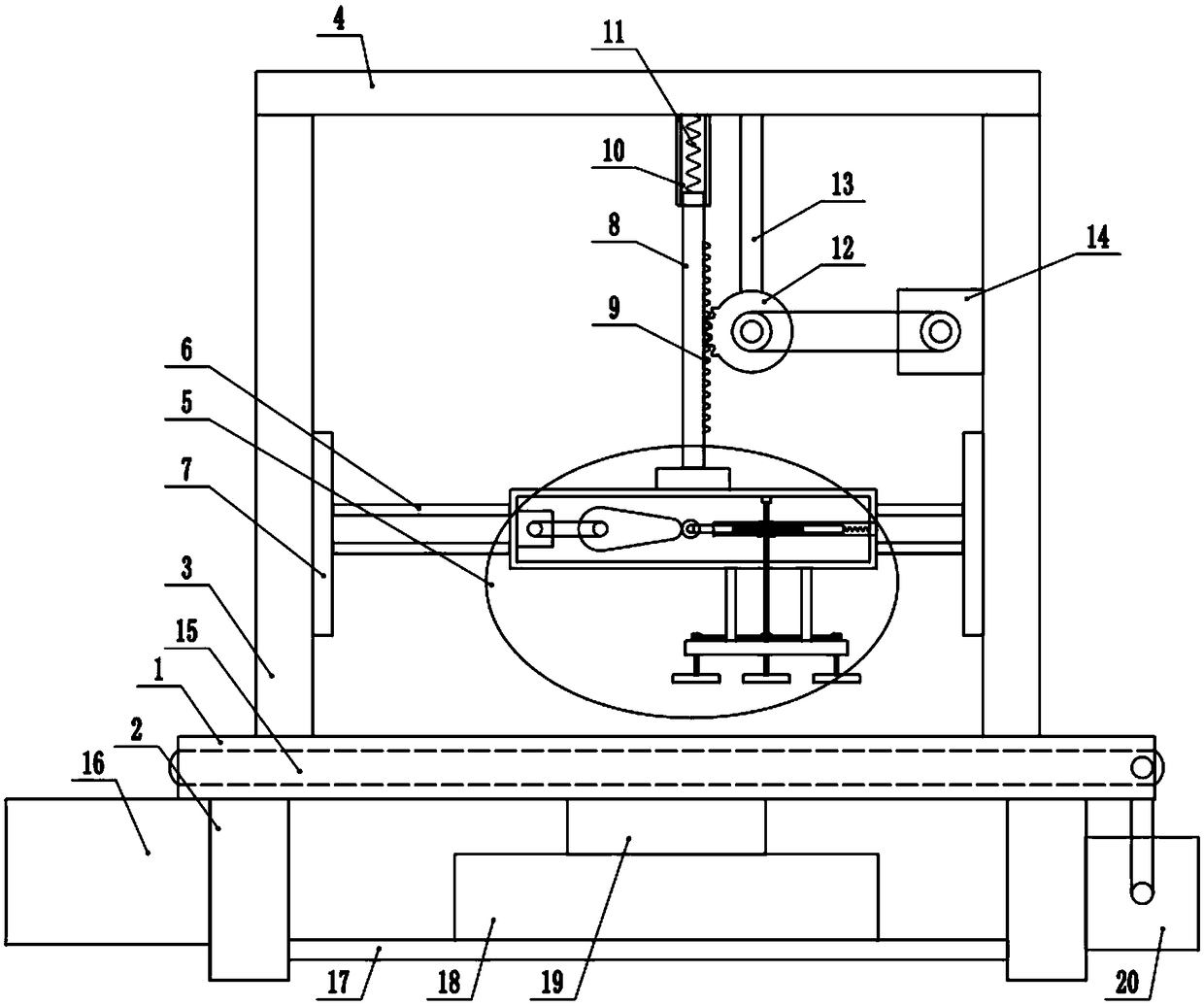

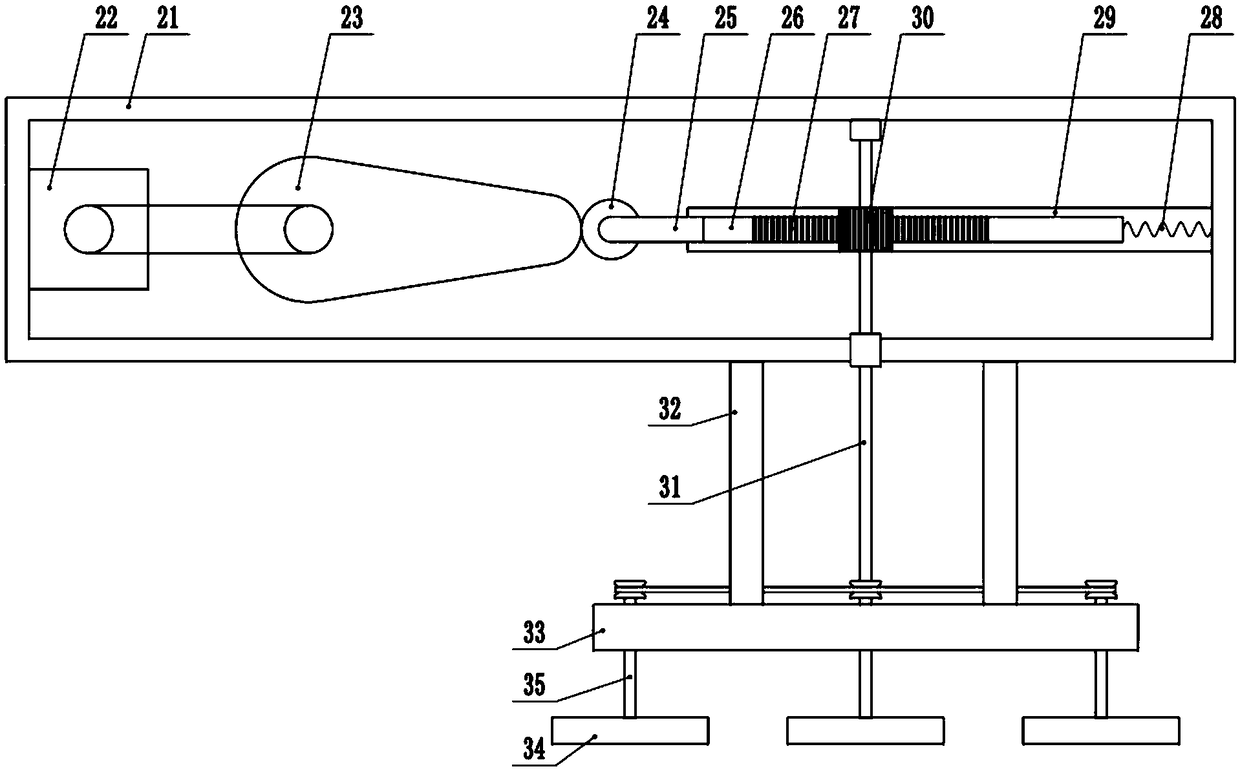

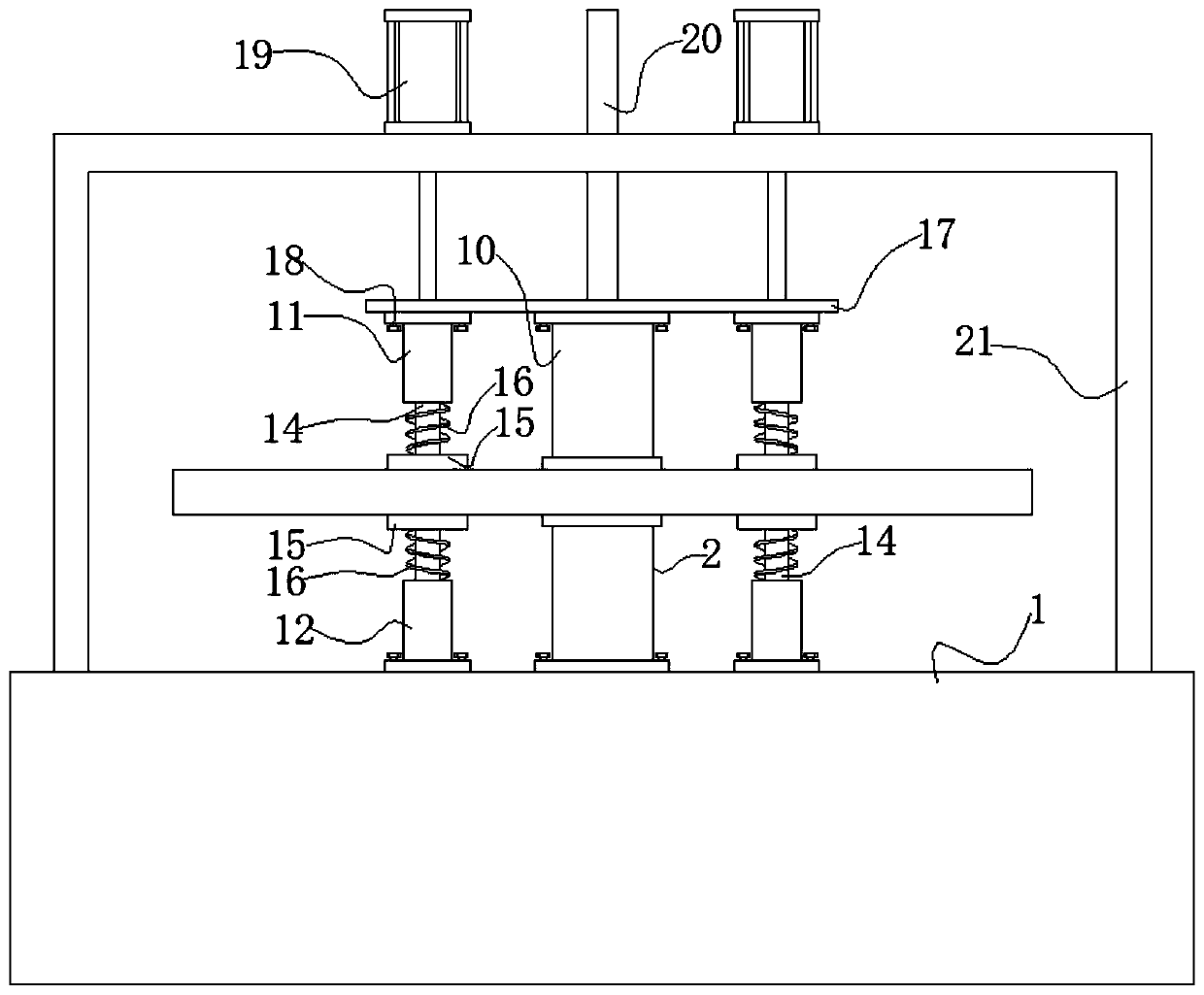

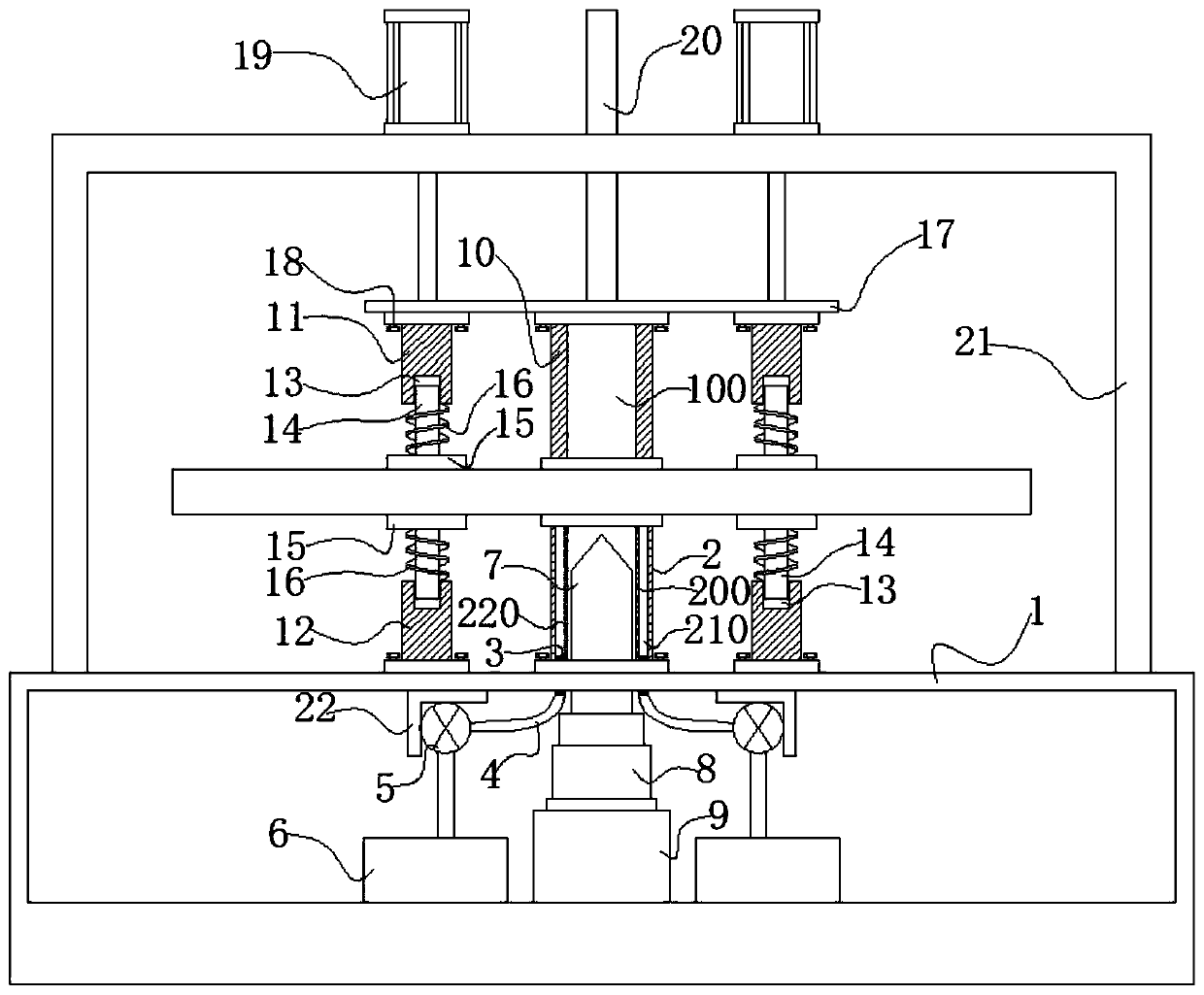

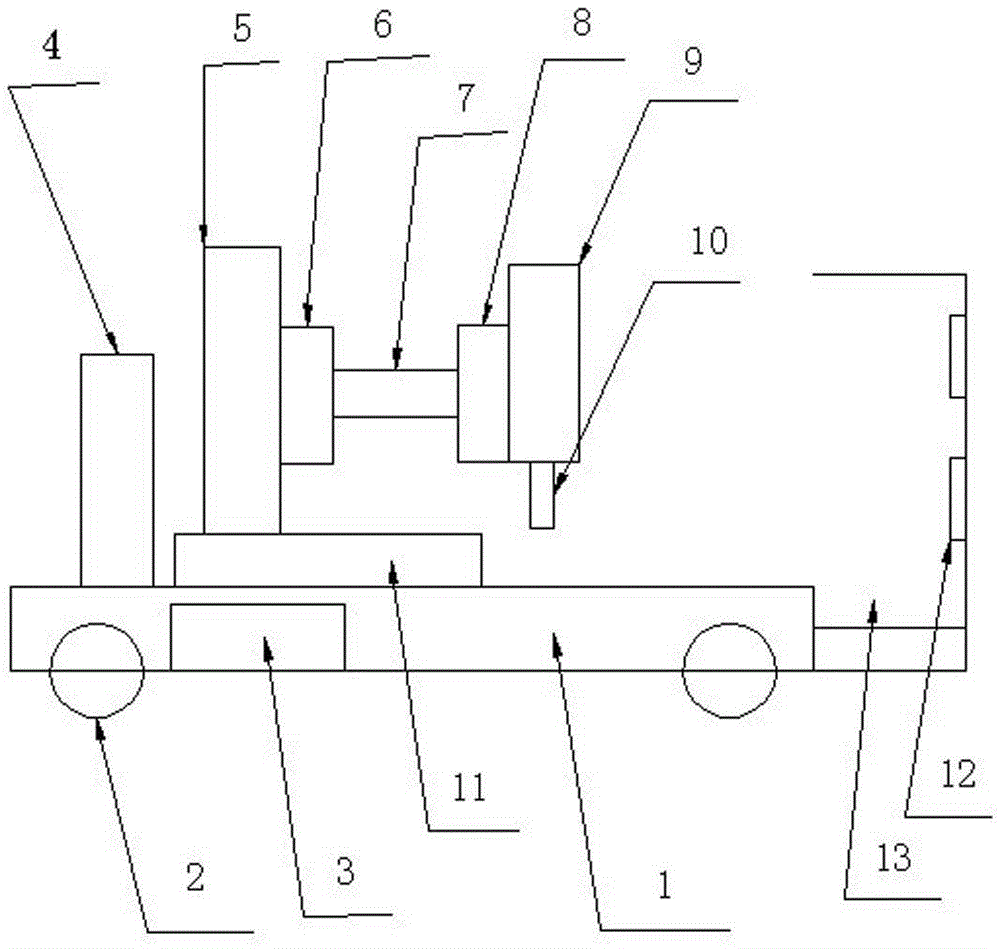

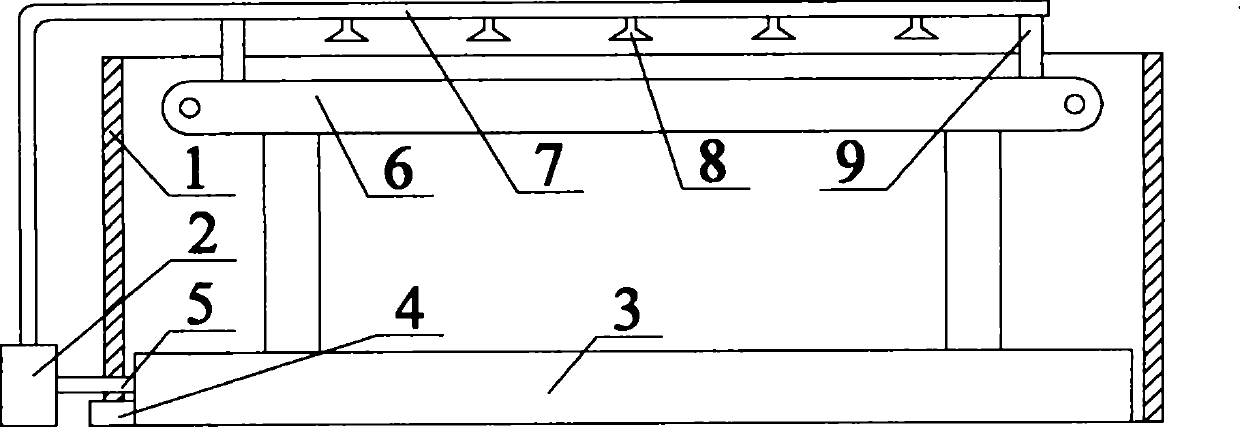

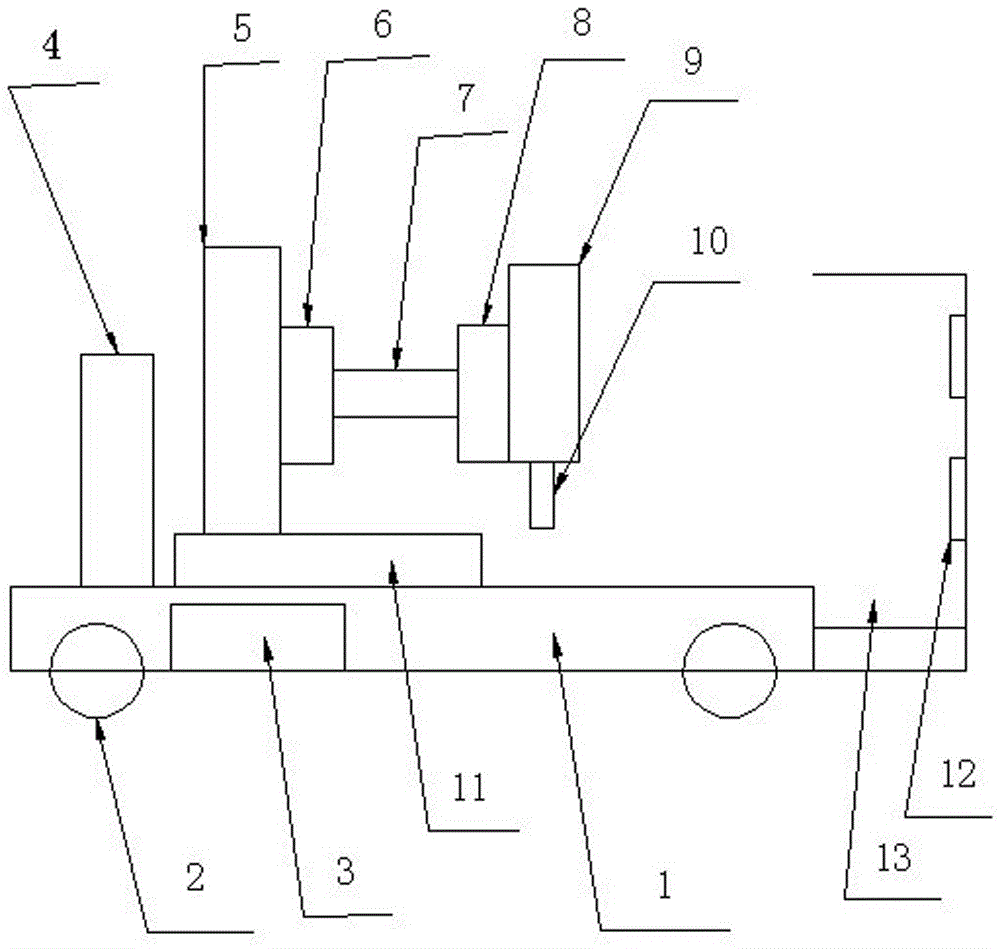

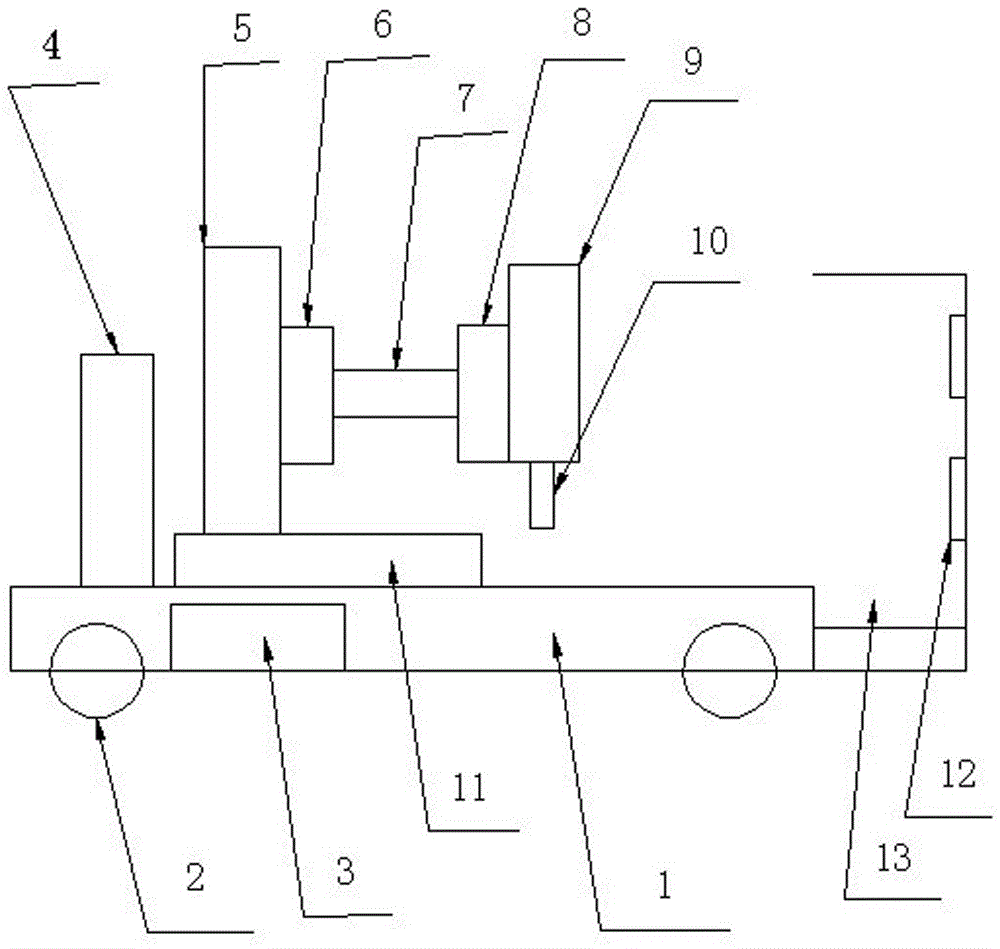

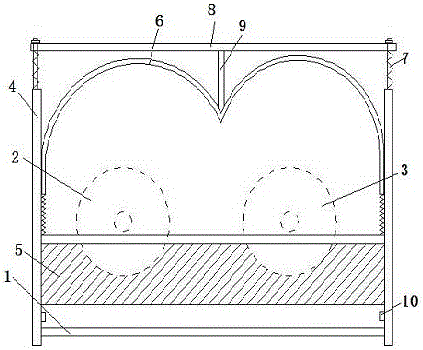

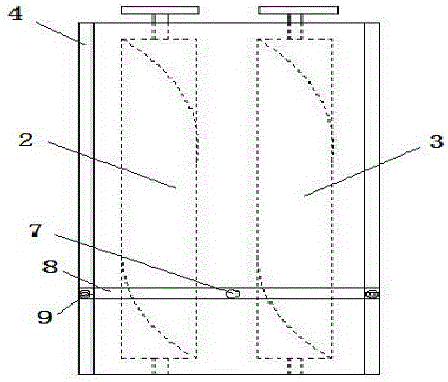

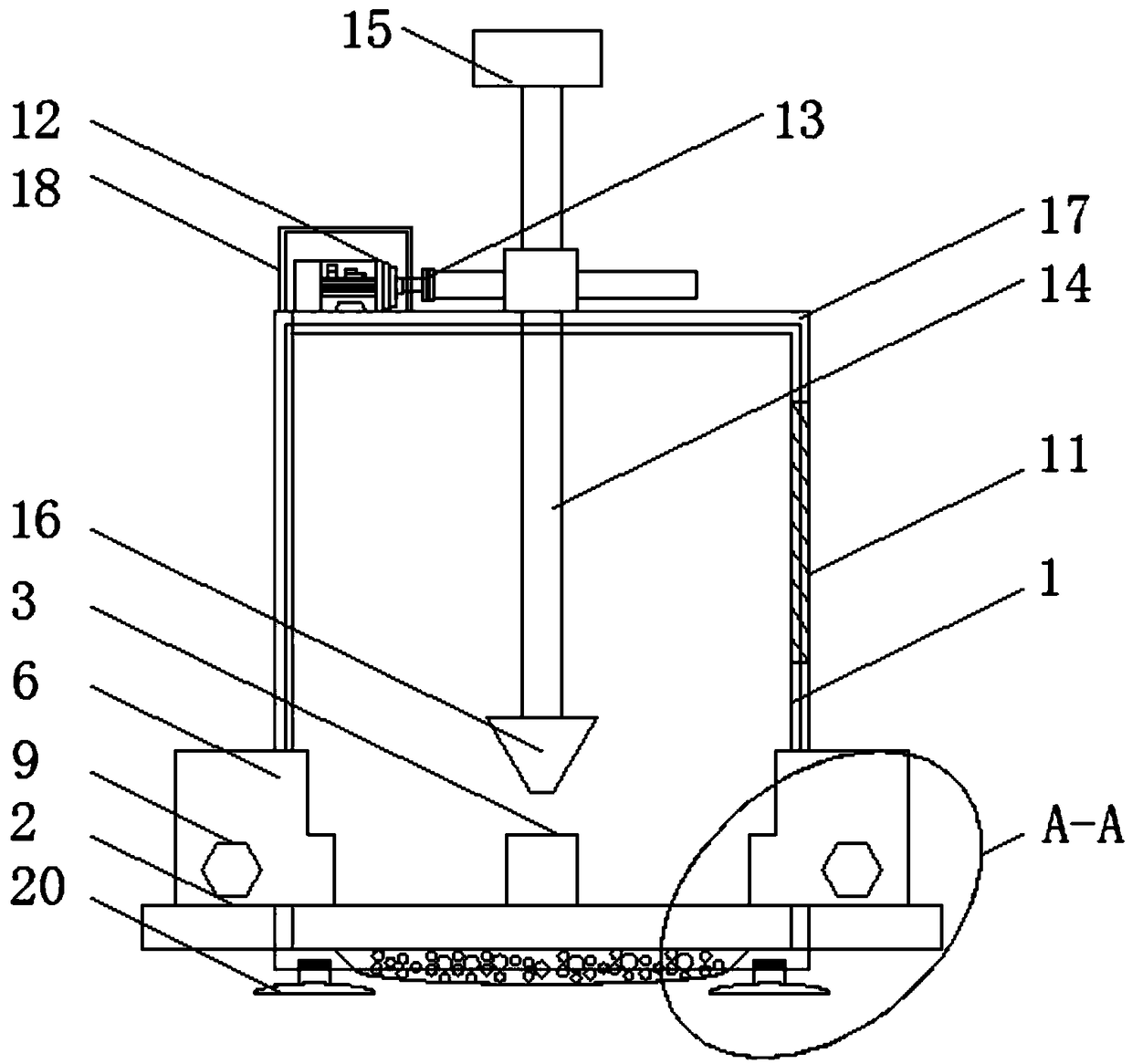

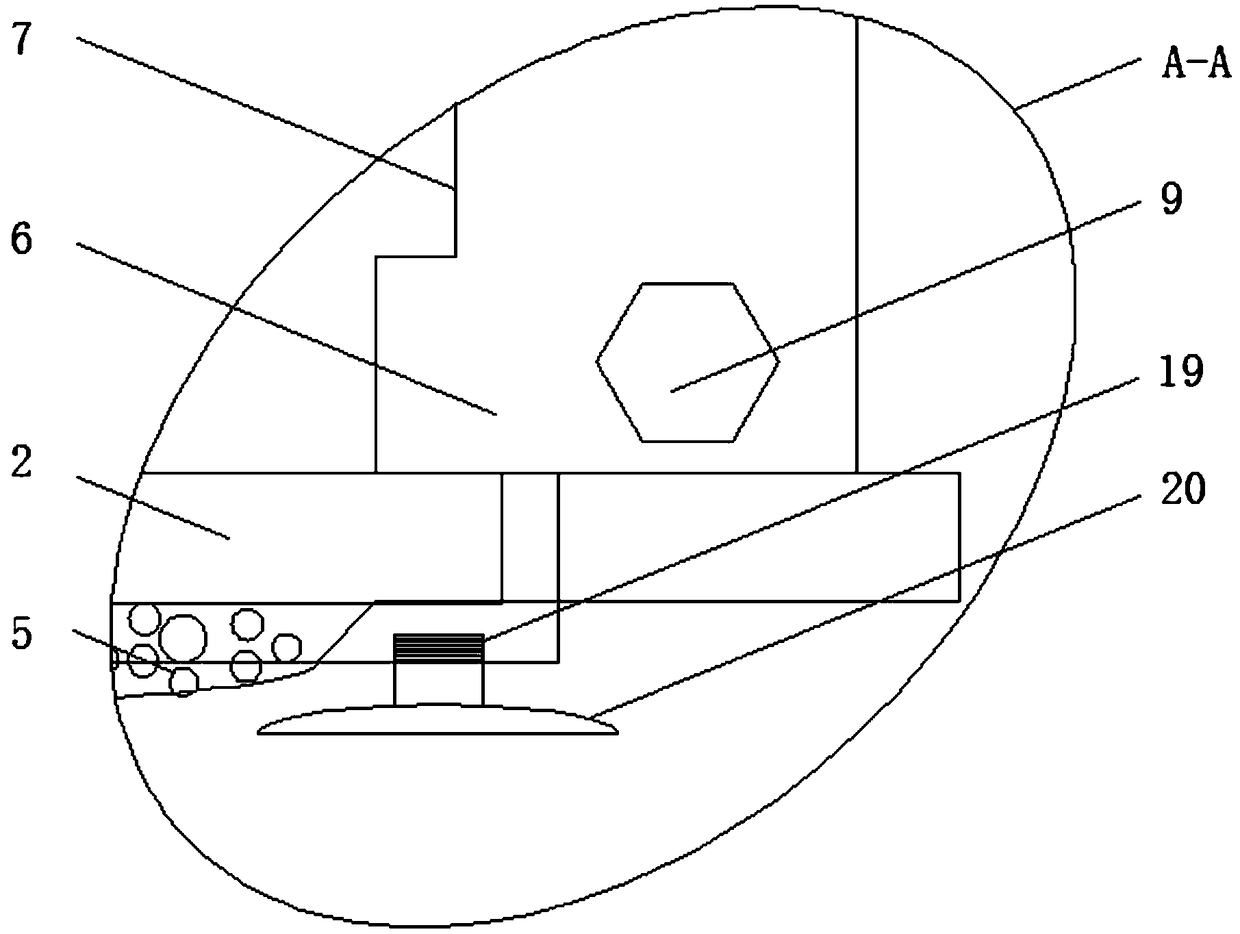

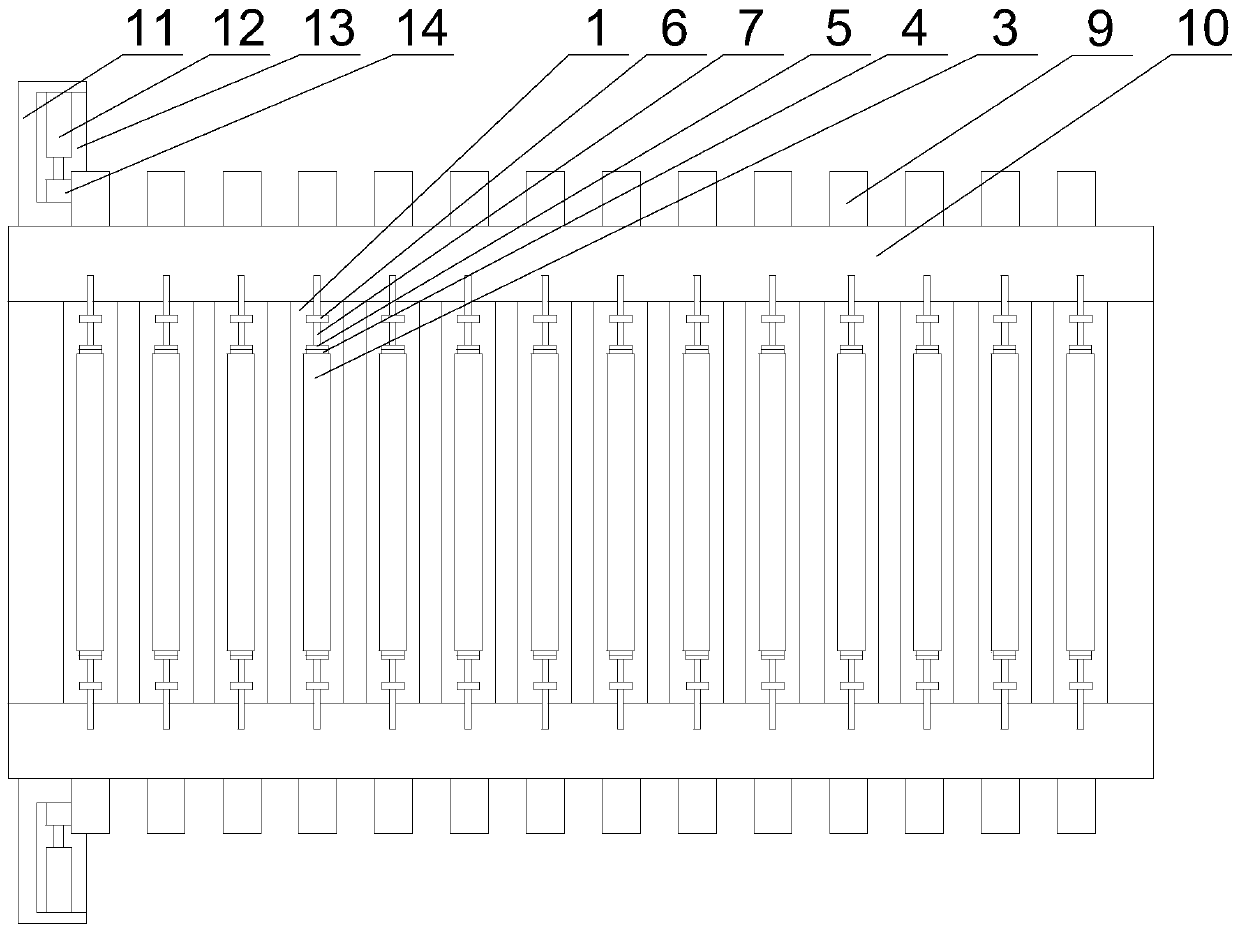

Batch PCB continuous grinding device used in production process of electronic parts

InactiveCN109048537AImprove grinding effectImprove grinding efficiencyEdge grinding machinesGrinding carriagesEngineeringMechanical engineering

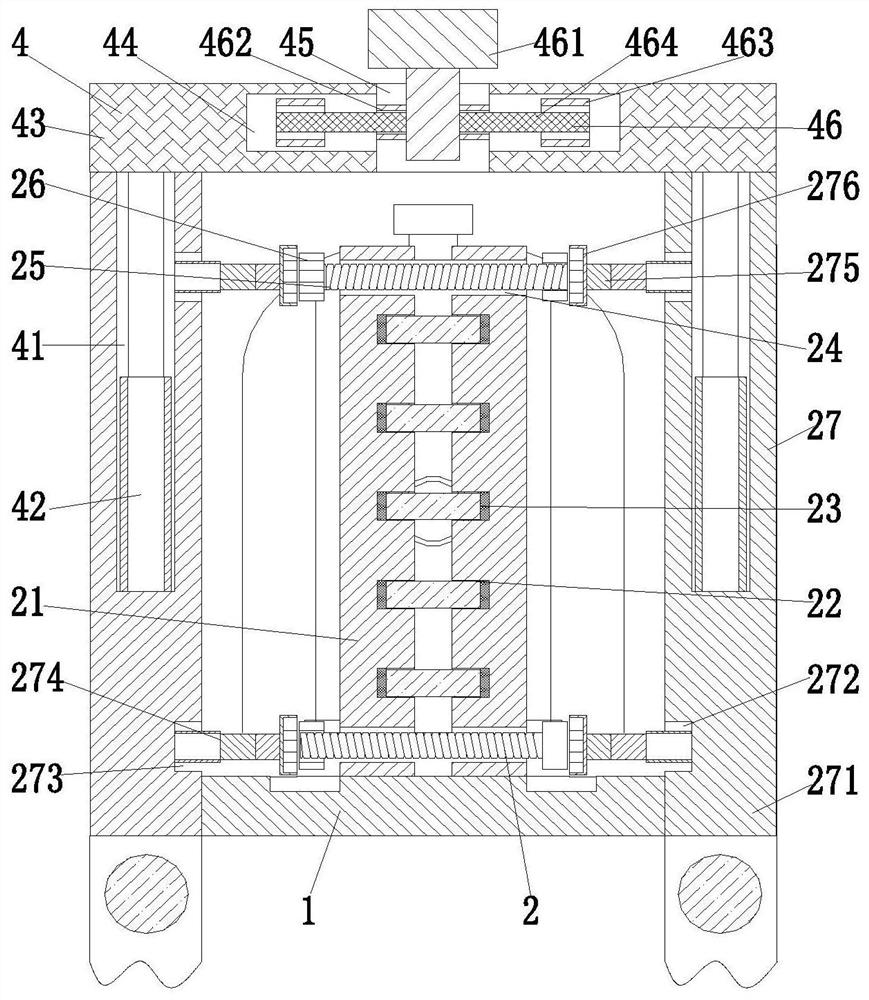

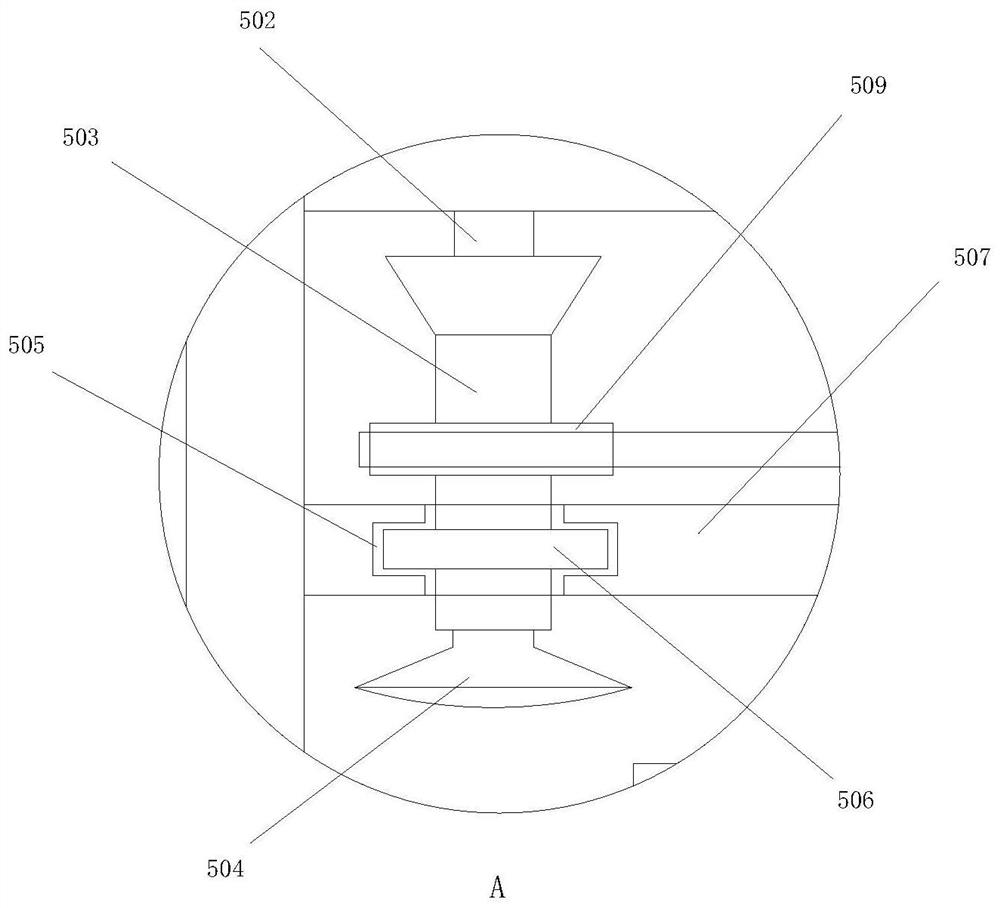

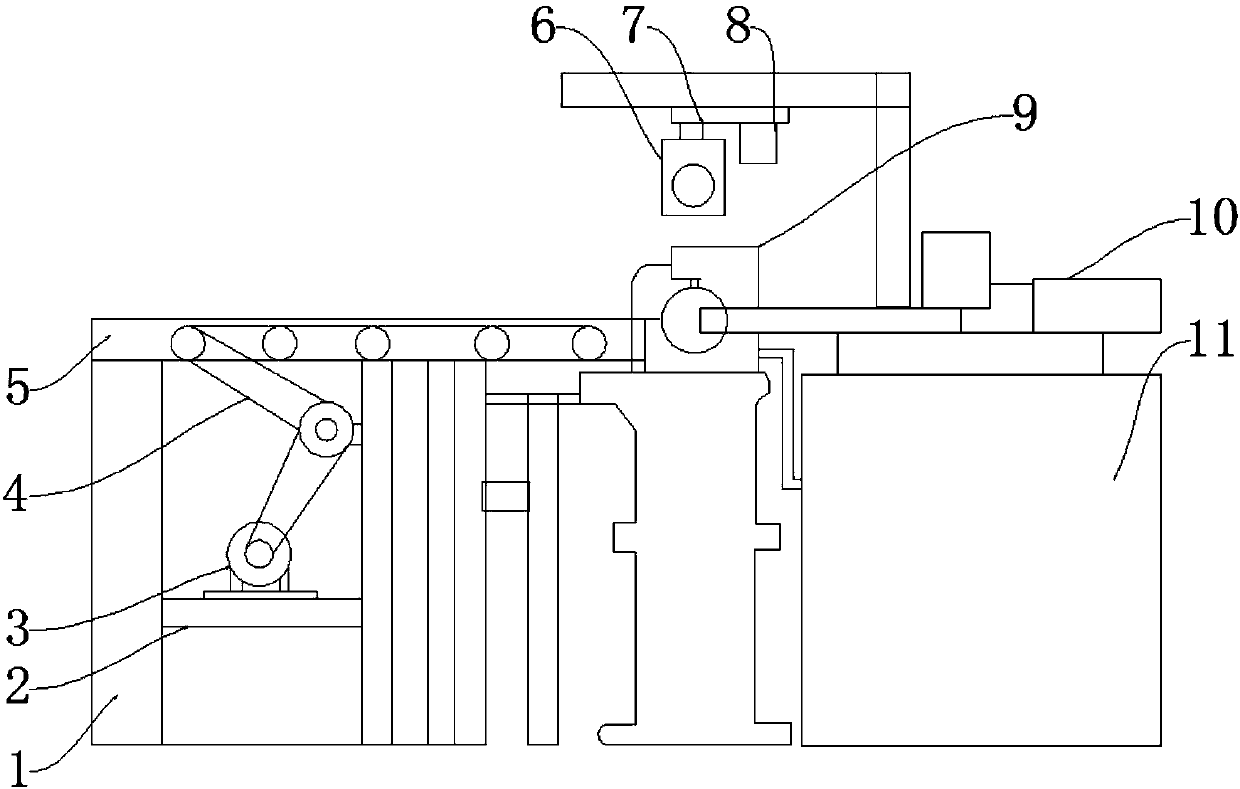

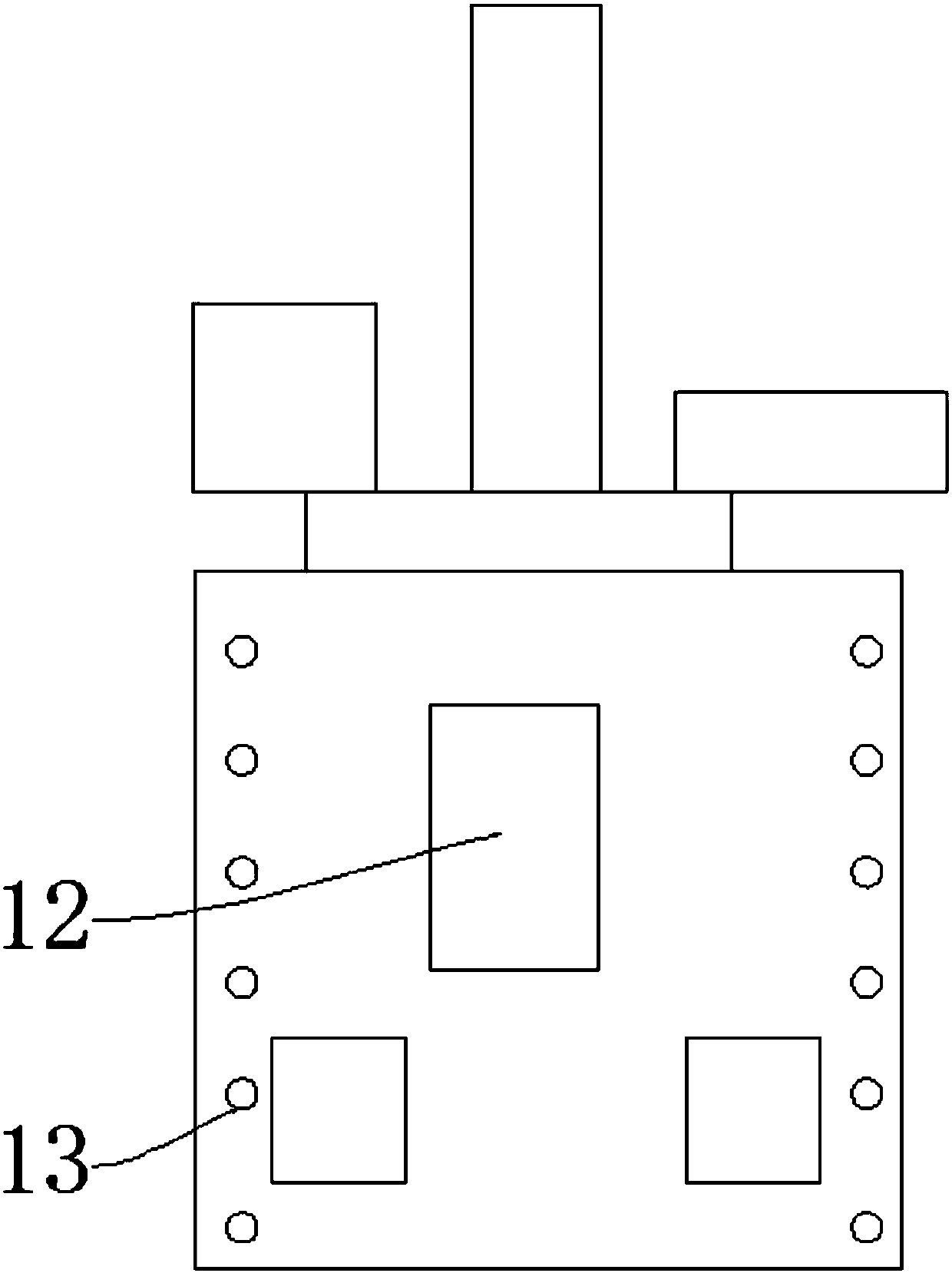

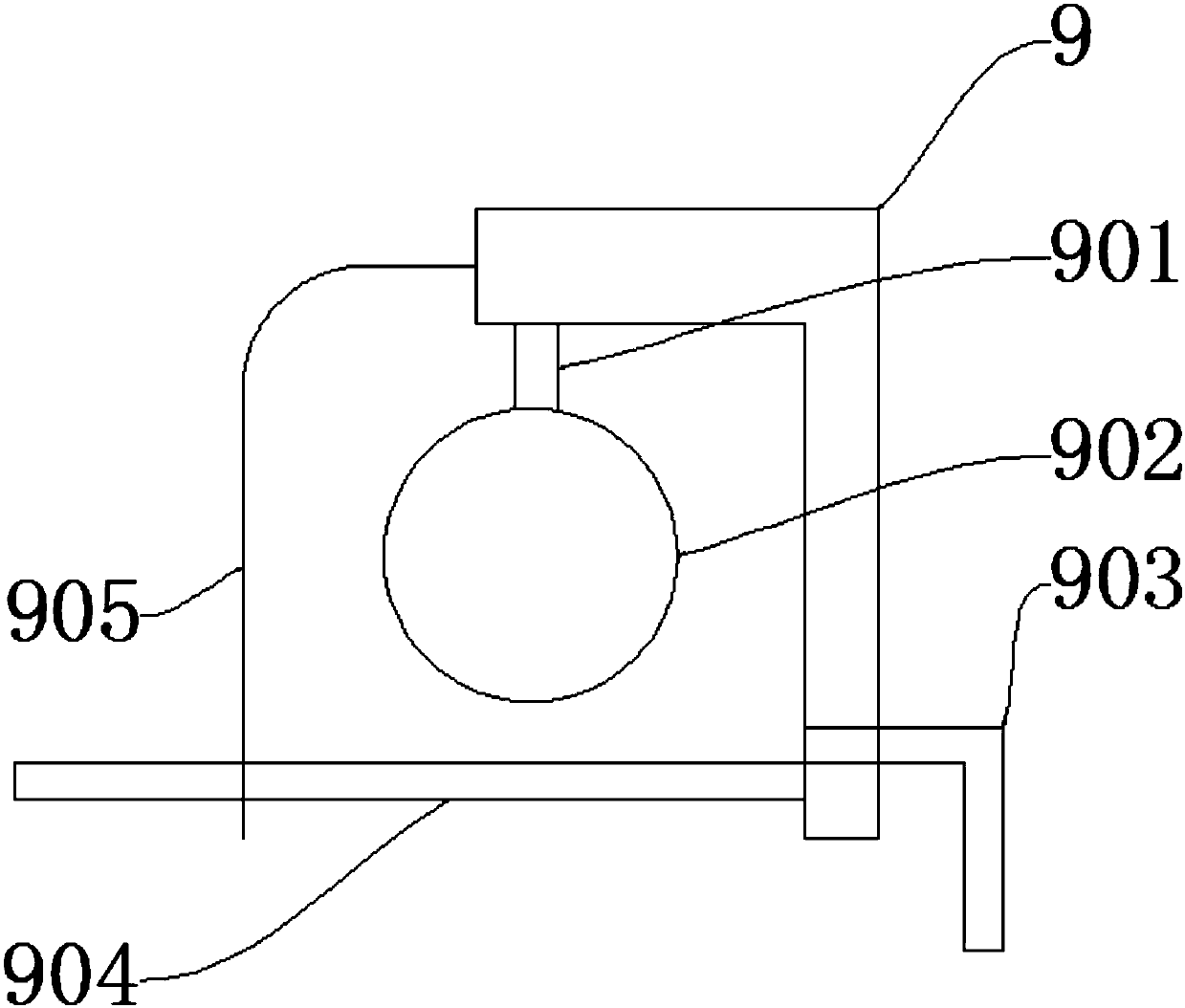

The invention discloses a batch PCB continuous grinding device used in the production process of electronic parts. The batch PCB continuous grinding device comprises a transport frame, the four corners of the bottom end of the transport frame are provided with support legs, the both ends of the transport frame are provided with side frames, the top ends of the side frames are fixedly provided witha top frame, the transport frame is internally provided with a conveying mechanism, a grinding device is arranged above the conveying mechanism, sliding rods are fixedly connected to the both sides of the grinding device, first sliding rails corresponding to the sliding rods are arranged on the side frames, the top end of the grinding device is connected with a lifting rod, the exterior of the top end of the lifting rod is sleeved with an outer sleeve, the outer sleeve is fixedly connected with the top frame, and the outer sleeve is internally provided with a pressing spring fixedly connectedwith the lifting rod, one side of the lifting rod is provided with a first gear, the lifting rod is provided with a first rack engaged with the first gear, a first motor is fixed to the side frames,and the first motor is in transmission connection with the first gear. According to the batch PCB continuous grinding device, the grinding effect of the outer surface of a PCB is good, the grinding efficiency is high, and a clean and tidy working environment can be created.

Owner:刘会

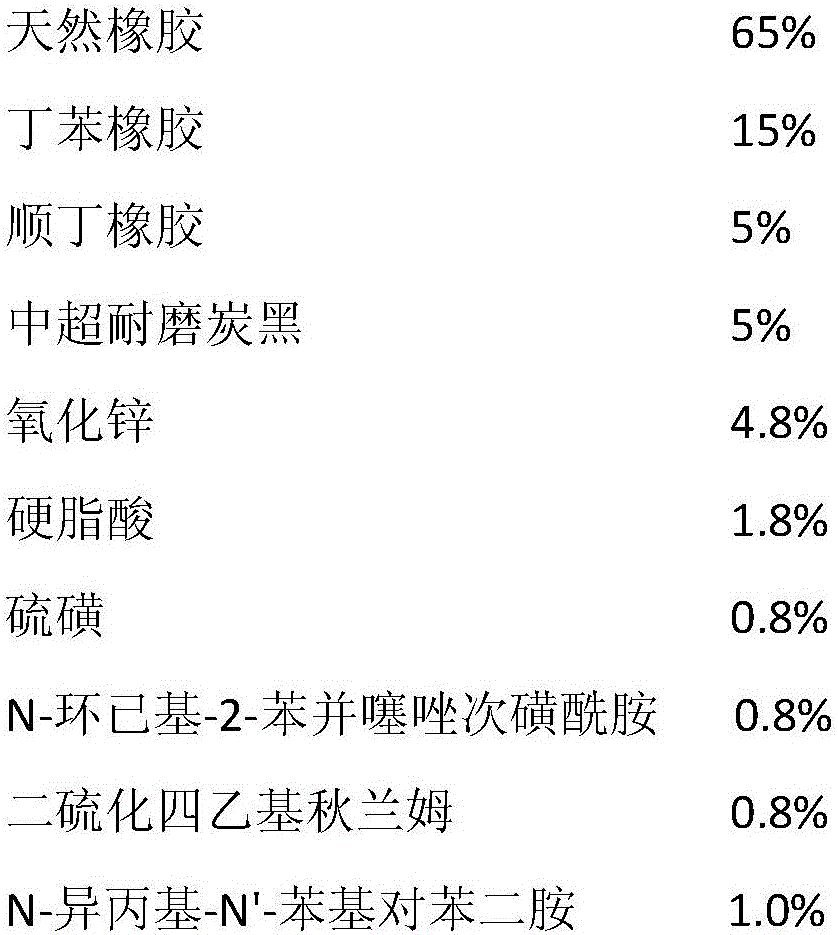

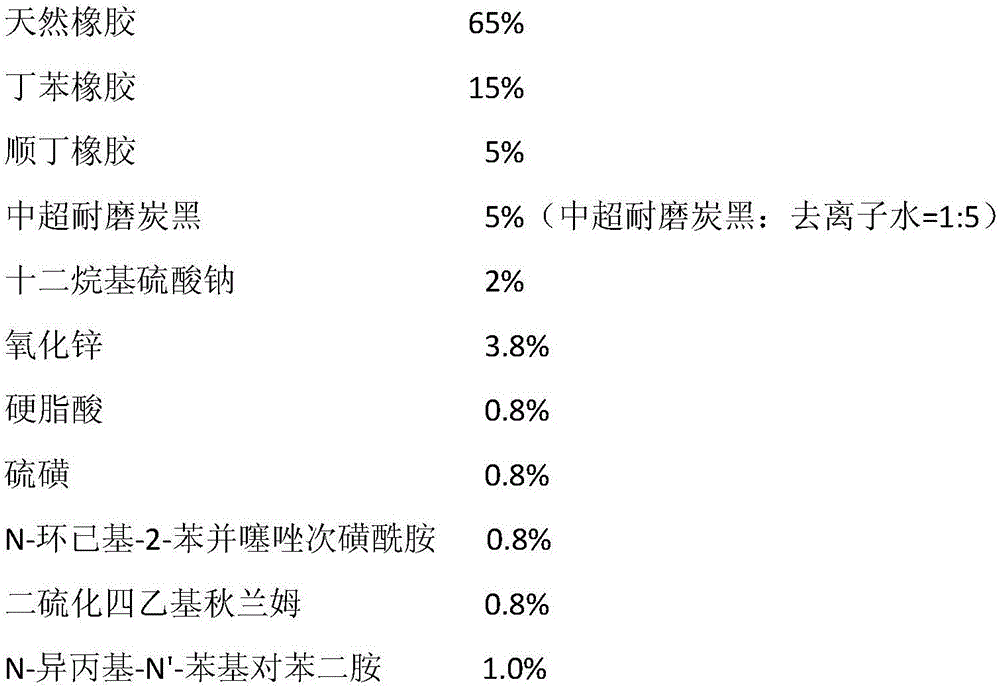

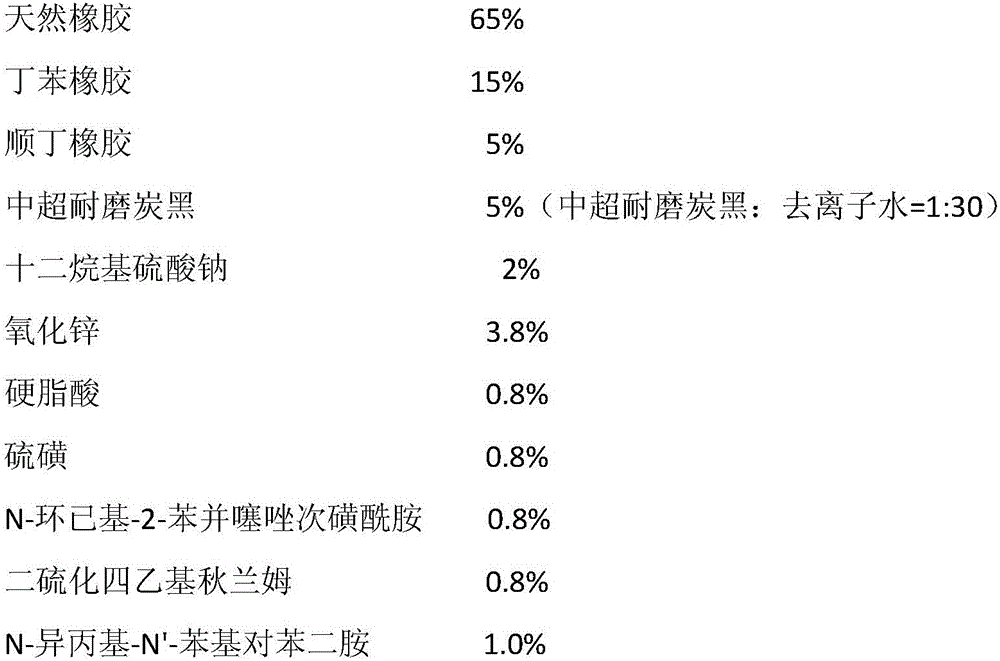

Preparation method of olefin rubber/filler blend vulcanized rubber

The invention discloses a preparation method of olefin rubber / filler blend vulcanized rubber. The method comprises the following steps: preparing a filler predispersion solution; plasticizing unvulcanized natural rubber by a rubber Banbury mixer, mixing with styrene-butadiene rubber and cis-1,4-polybutadiene rubber, increasing the temperature of the Banbury mixer to 110-160 DEG C, adding the filler predispersion solution into the rubber Banbury mixer, compounding, evaporating to remove water, and drying with hot air to obtain an olefin rubber / filler mixture; adding zinc oxide, stearic acid, a vulcanizing agent, an accelerator and an anti-aging agent into a rubber open mill or Banbury mixer, compounding uniformly, discharging, and standing to obtain the olefin rubber / filler compounded rubber; and vulcanizing the olefin rubber / filler compounded rubber on a flat vulcanizing machine to obtain the olefin rubber / filler blend vulcanized rubber. The method has the advantages of simple technique, no solvent pollution and no flying dust, is green and environment-friendly, and can be widely used for mixing multiple fillers and rubber.

Owner:SOUTH CHINA UNIV OF TECH

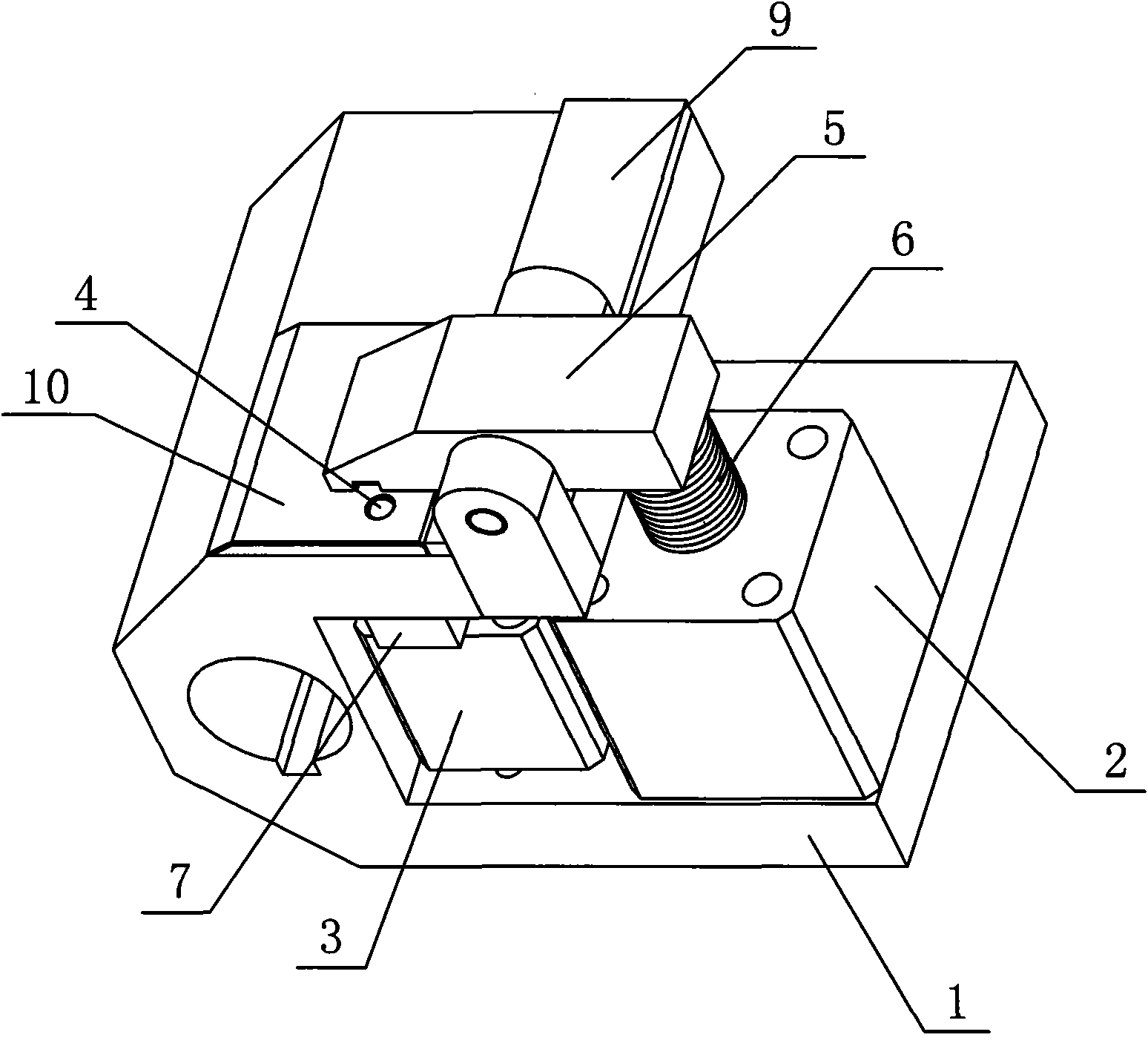

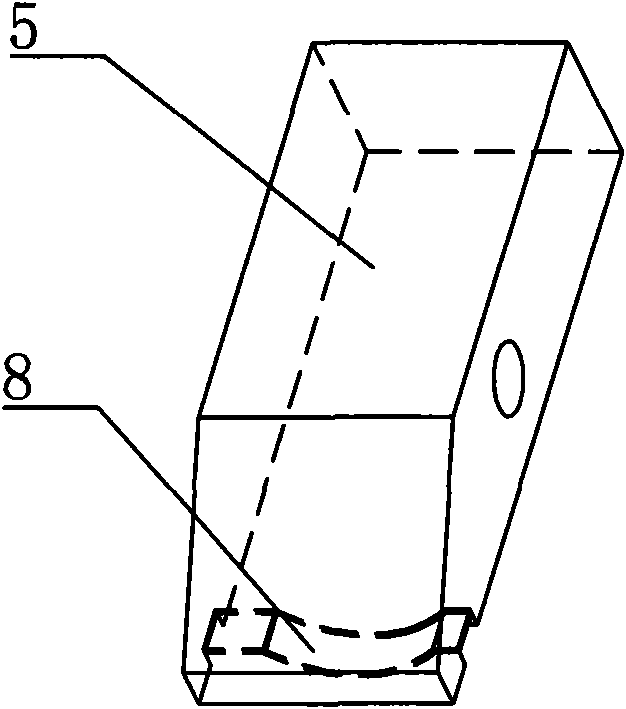

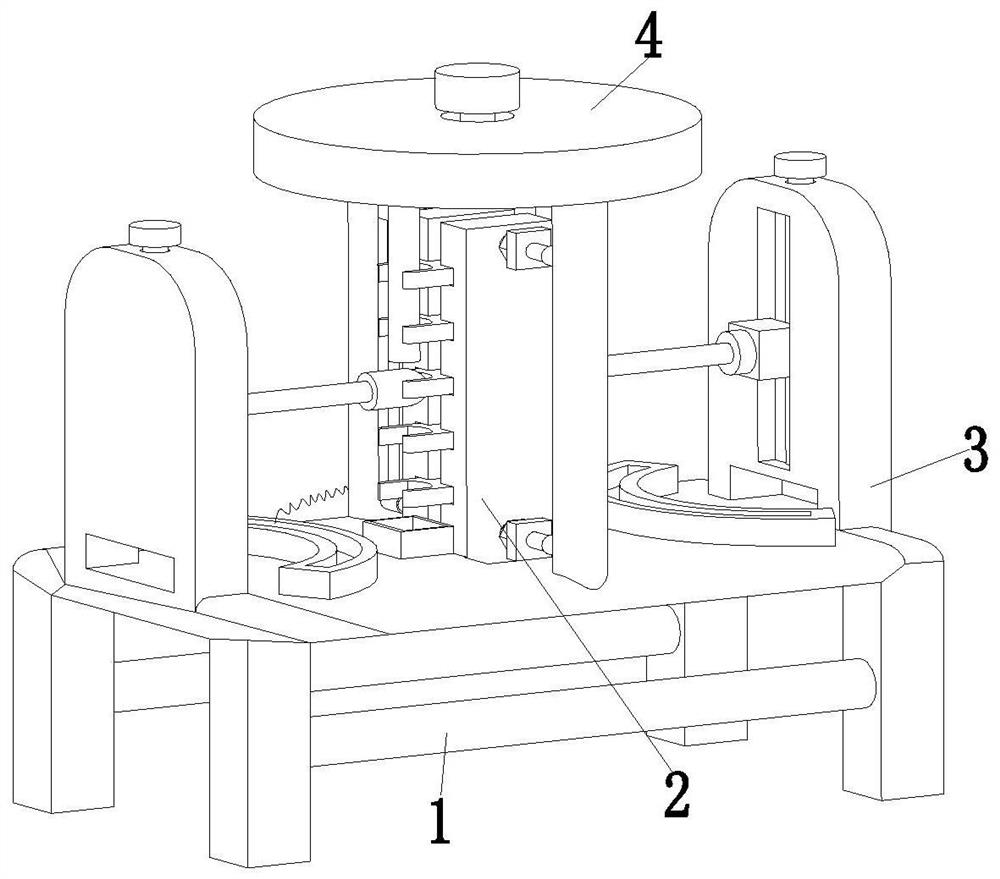

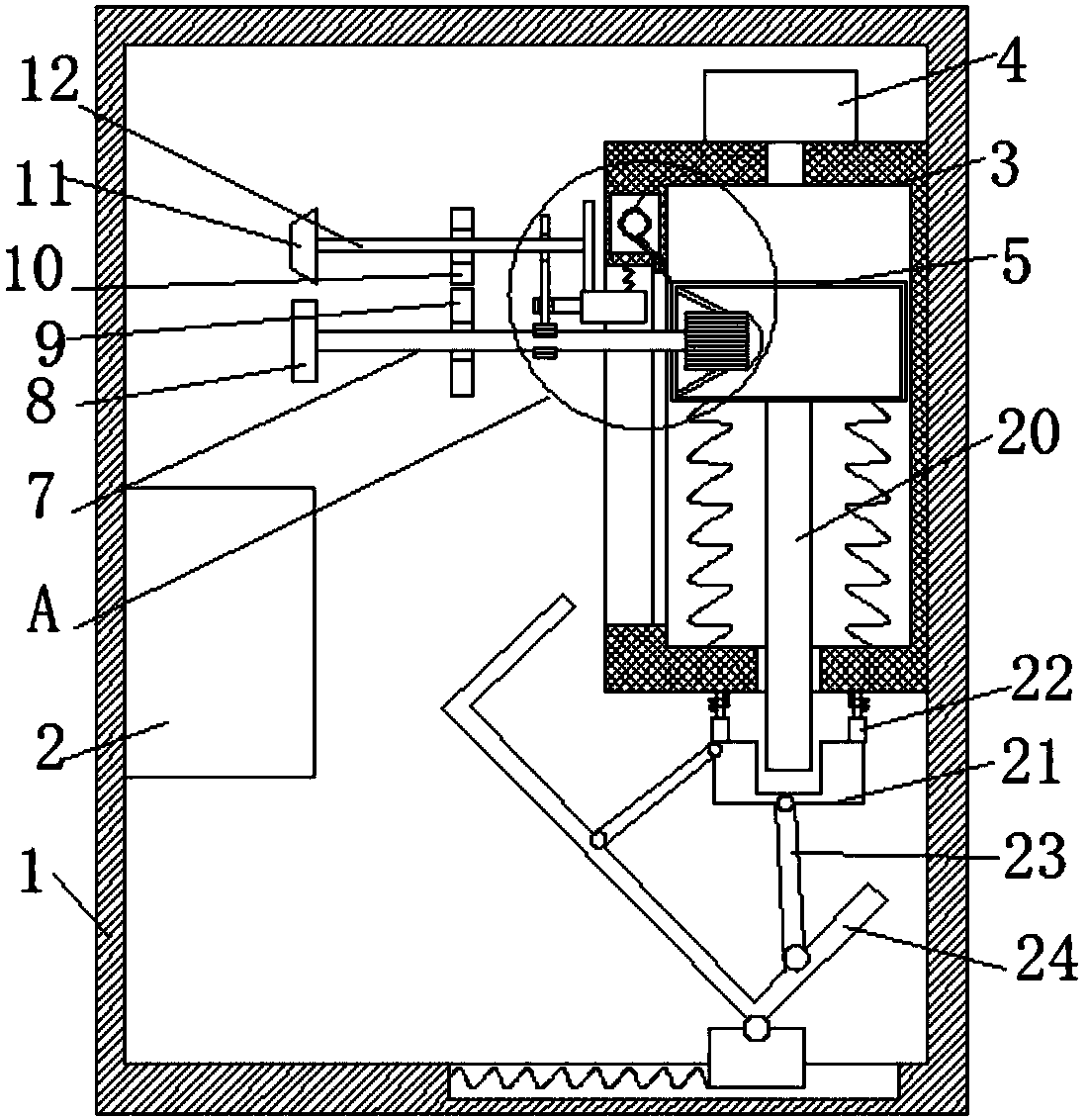

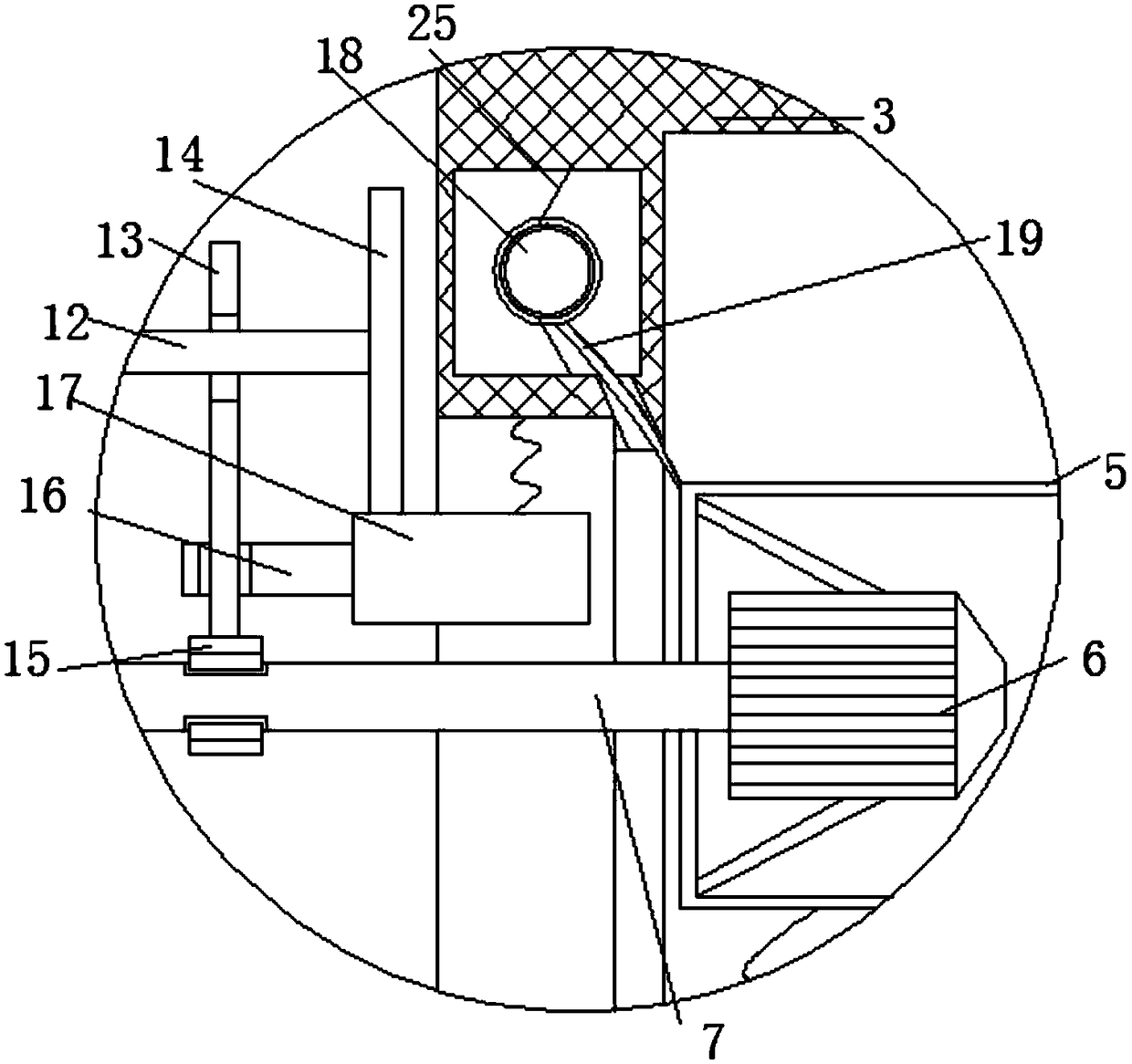

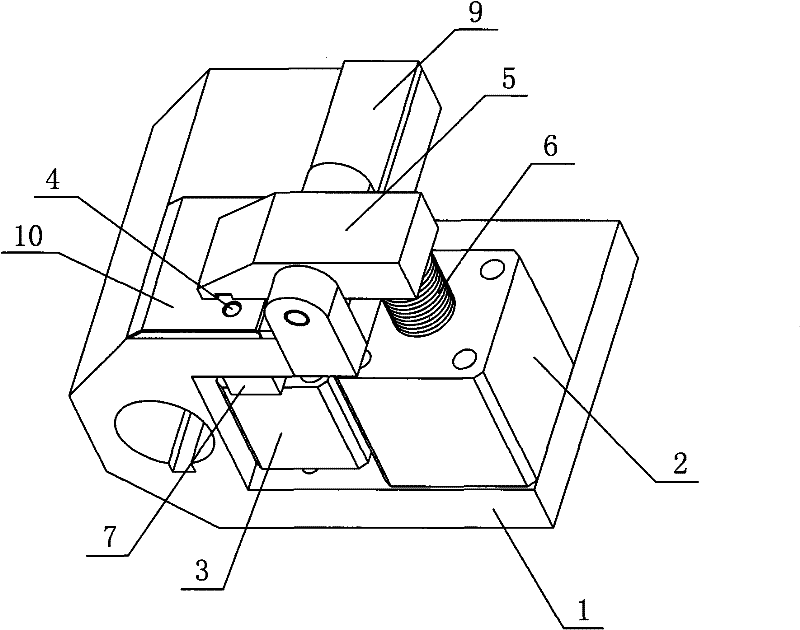

Positioning device for automatically processing blades of push scissors for haircut

InactiveCN101623839ARealize automatic positioningSmooth transmissionOther manufacturing equipments/toolsWorking environmentMachining process

The invention discloses a positioning device for automatically processing blades of a pair of push scissors for haircut, which is characterized by comprising a positioning base, a positioning pin and a press plate, wherein the press plate is axially connected to the positioning base, the back end of the press plate is provided with an elastic jacking device, a through hole is arranged on the positioning base, the positioning pin and the through hole are in sliding fit, and an automatic lifting drive device is connected to the positioning pin. The positioning device has the advantages that the automatic positioning of the blades can be realized by the device; when a previous feeding procedure delivers the blades to the positioning base, the front end part of the press plate presses the blades in advance by the elasticity of a spring; when positioning holes on the blades are aligned with the through hole on the positioning base, a drive rod of a second air cylinder drives the positioning pin to raise upwards and penetrate into the positioning holes of the blades, then a jacking rod of a first air cylinder jacks upwards to drive the press plate to press the blades, and the positioning process is finished; the whole process has no need of artificially delivering the blades into the positioning device for positioning, the work efficiency is high, and the whole processing process can be carried out in a closed environment so that the working environment is clean and tidy.

Owner:王夏生

Heavy belt-type movement machine

The invention discloses a heavy belt-type movement machine, which comprises a rack and a bearing roller machine arranged on the rack, wherein the bearing roller machine comprises a support,and at least a drive roller and a plurality of driven rollers arranged on the support, the drive roller is connected with a roller drive motor through a driving belt, the drive roller and each driven roller are connected by the driving belt, two travelling wheels are installed on two sides of the rack repectively, a track is arranged to match with the travelling wheels, the travelling wheels are connected with a travelling wheel drive motor through a transfer group and the travelling wheel on at least one side of the rack is installed with a limit guide wheel. According to the invention, the heavy belt-type movement machine has a simple and compact structure and small occupied space, and is stable and reliable; can bear heavy workpiece, and is easy to maintain by adoption of belt-type drive; and the adjustable range of the transfer speed is wide, and the flexibility of the whole logistics transportation system is better, thereby being helpful for speeding up production rhythm, improving productivity and optimizing production process.

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

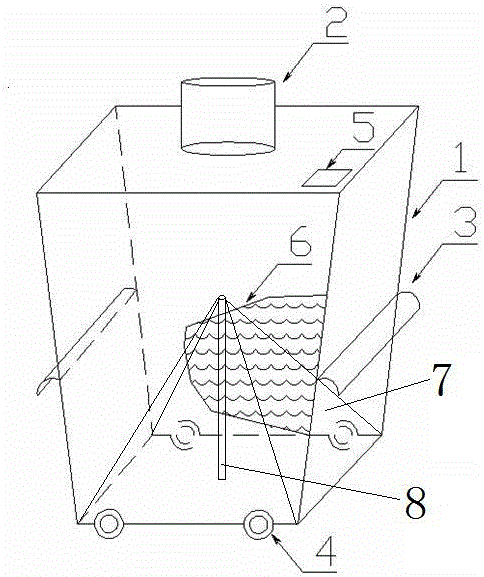

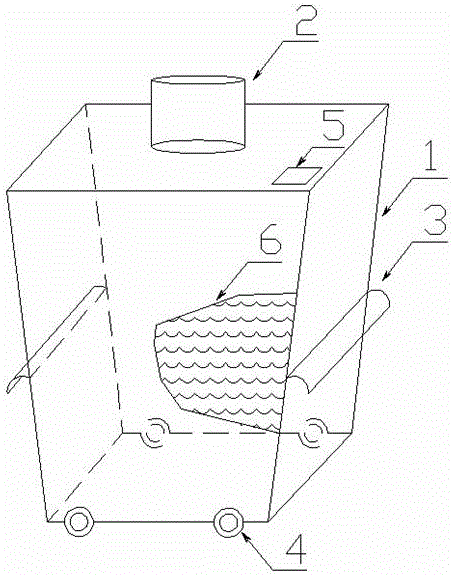

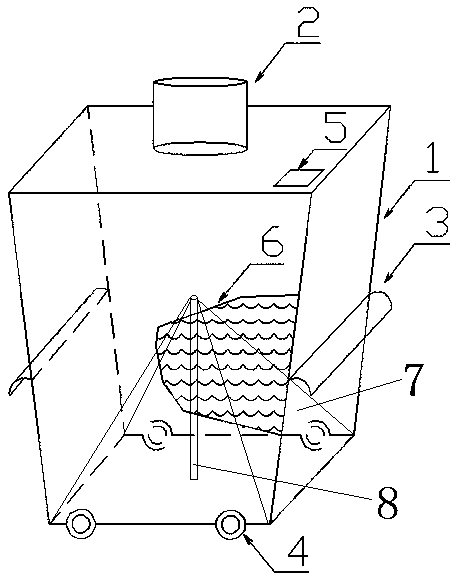

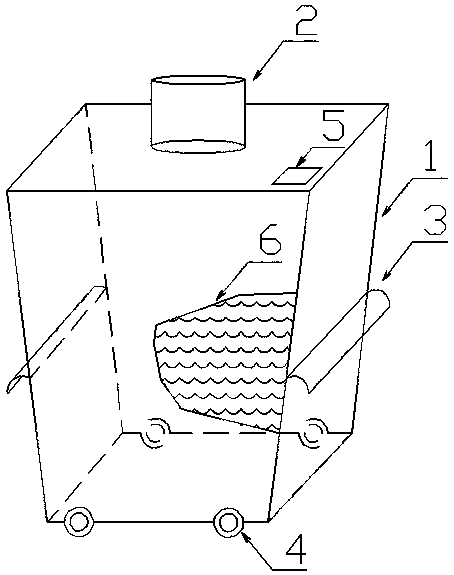

Dust collecting and treating device

ActiveCN106140771AEasy to disassemble and maintainEasy to moveDirt cleaningWater levelWaste management

The invention relates to a dust collecting and treating device. The dust collecting and treating device is characterized by comprising a collecting tank. A water level setting line is arranged in the colleting tank. A dust collecting opening is formed in the top of the collecting tank. A dust collecting and balancing device is arranged in the collecting tank. Wheels are arranged at the bottom of the collecting tank. A dust guide groove is formed in the inner wall of the collecting tank. During use, dust collecting liquid accounting for 1 / 3 of the volume of the collecting tank is loaded into the collecting tank, and accordingly dust can be absorbed sufficiently and dust can be prevented from overflowing and flying off. The dust collecting and balancing device guarantees that the dust entering the collecting tank does not pile up in the middle of the collecting tank, the dust evenly slides towards the periphery of the collecting tank along a collecting hood, the dust can be dissolved in water favorably, and even dust storage is benefited. A top cover plate is provided with an observation hole, the water level condition in the collecting tank can be observed, and a user can judge that the collecting tank is full and needs to be cleaned when the water level reaches a certain height.

Owner:TAOPU SEWAGE TRAEATMENT PLANT OF SHANGHAI CHENGTOU SEWAGE TREATMENT

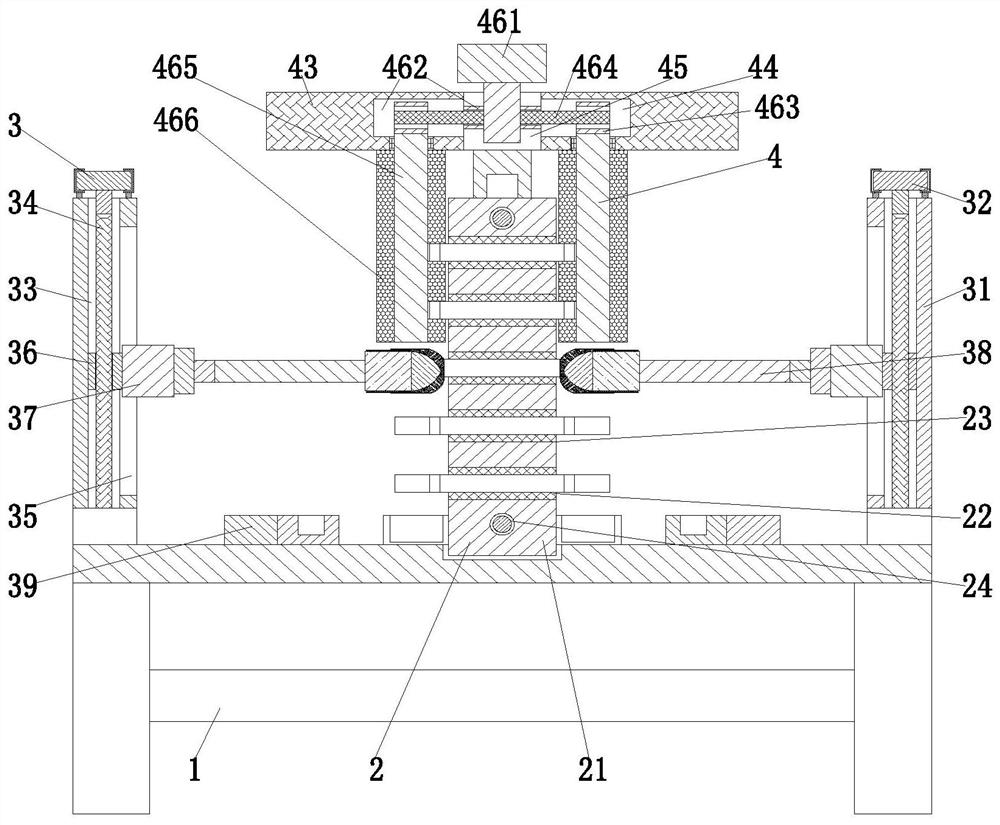

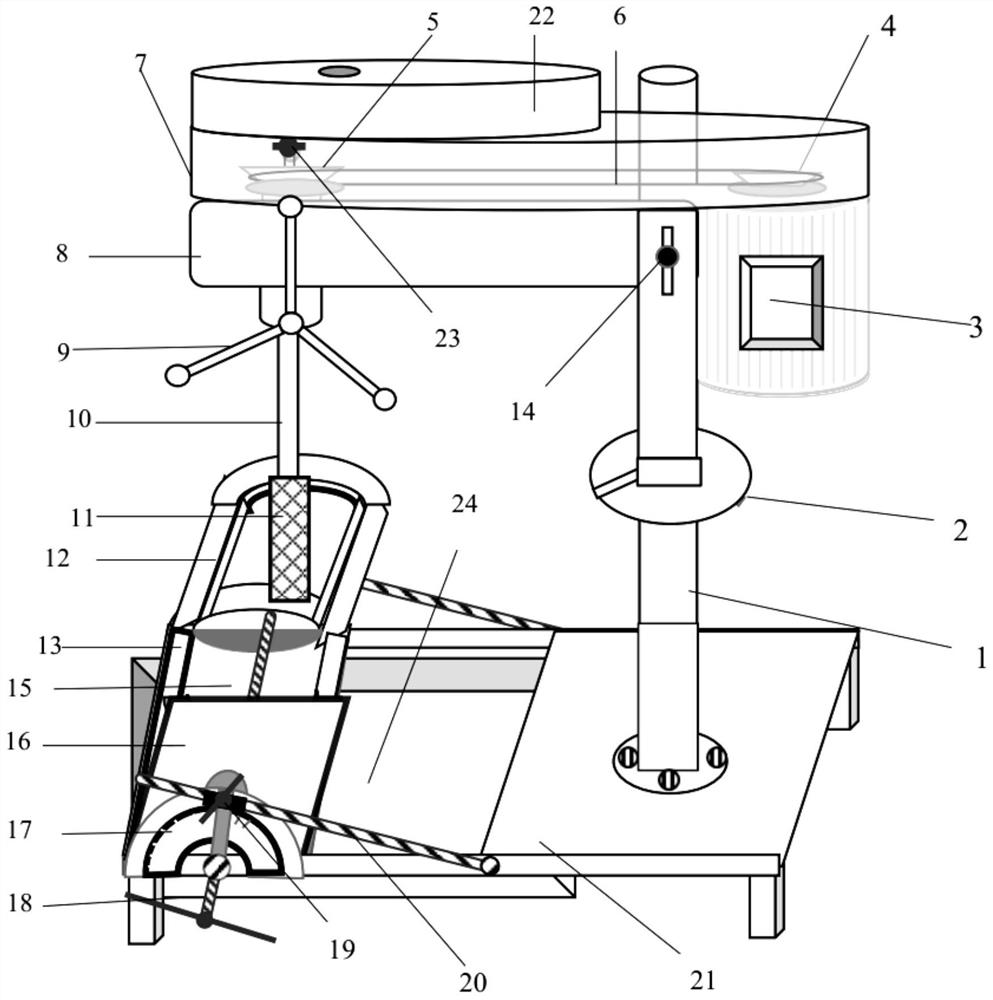

Surface finish machining treatment system and treatment process after casting molding of casting part

ActiveCN111823066AReduces the risk of wearing out the wrenchReduce manual labor intensityEdge grinding machinesGrinding drivesSurface finishPolishing

The invention relates to a surface finish machining treatment system and treatment process after casting molding of a casting part. The surface finish machining treatment system comprises a supportingframe, a clamping device, grinding devices and a cleaning device, the clamping device and the cleaning device are arranged in the middle of the supporting frame, the cleaning device is located abovethe clamping device, and the grinding devices are symmetrically installed at the left end and the right end of the supporting frame; the clamping device comprises a clamping plate, clamping grooves, rubber pads, threaded holes, a locking bolt, a nut cap and a locking mechanism, a groove is formed in the middle of the supporting frame, the clamping plate is installed in the groove in a sliding fitmode, the clamping grooves are evenly formed in the clamping plate, the rubber pads are arranged in the clamping grooves, and the threaded holes are vertically and symmetrically formed in the middle of the clamping plate. The problems that most of existing casting workpieces are polished manually through a polishing machine, the cambered surfaces of wrenches cannot be polished uniformly, castingsare abraded due to improper operation, the manual working efficiency is low, and the labor intensity is high can be solved.

Owner:江西晖旭实业有限公司

Waste plastic pelleting unit

InactiveCN107150418AControl the amount of feedFeed Quantity ObservationCoatingsEngineeringMechanical engineering

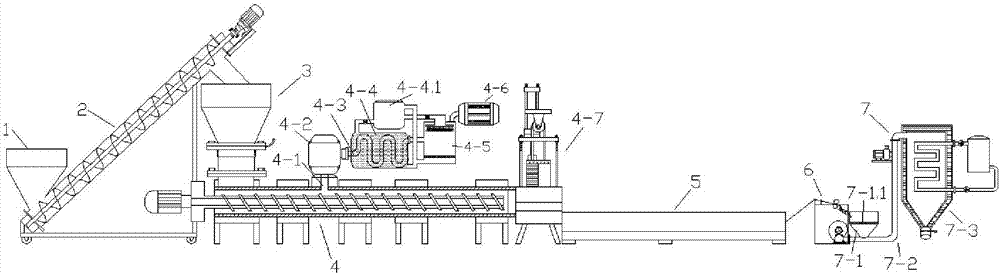

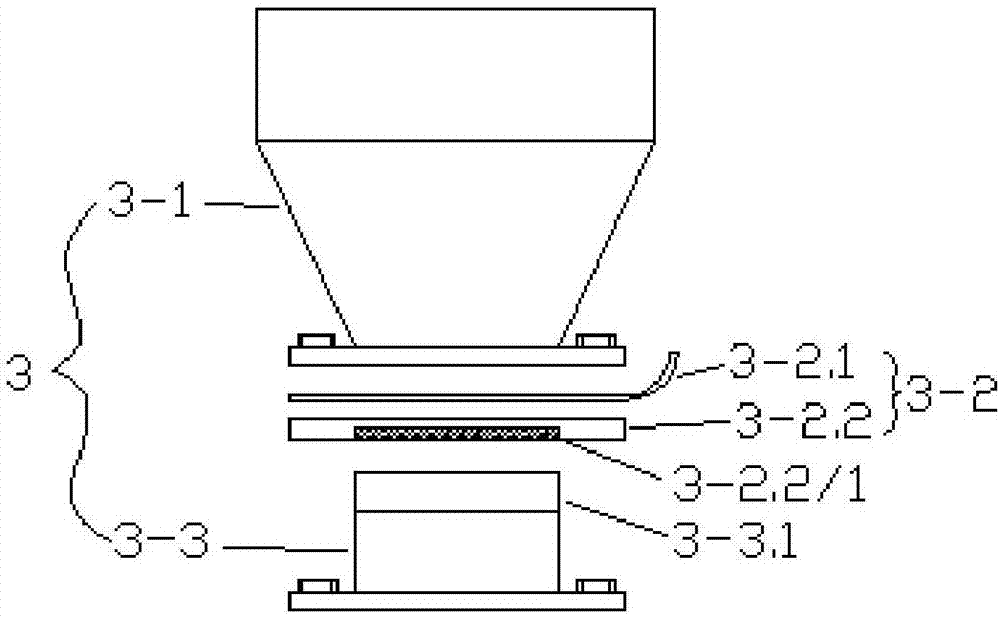

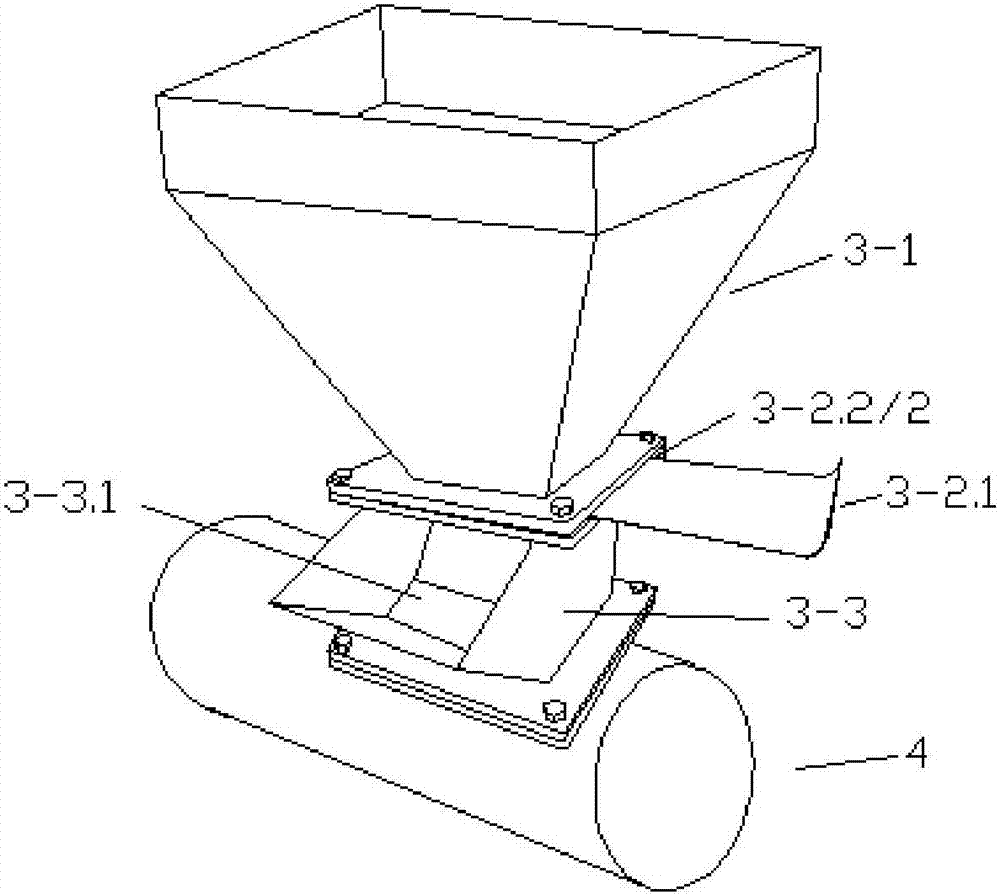

The invention discloses a waste plastic pelleting unit and relates to the technical field of plastic processing equipment. The waste plastic pelleting unit comprises a storage box, a transmission auger, a feeding device, a screw extruder, a cooling device, a granulator and a receiving device which are connected in sequence, wherein the feeding device comprises a first feeding hopper and a second feeding hopper; a flow intercepting assembly for controlling material flow rate is arranged under the first feeding hopper and comprises a flow intercepting plate and a connecting plate; the middle of the connecting plate is hollow; a groove allowing the flow intercepting plate to slide is formed in the connecting plate; the flow intercepting plate can control the material flow rate through sliding along the groove; a feeding filter screen is detachably arranged in the middle hollow part of the connecting plate; the second feeding hopper is connected with the flow intercepting assembly; a remainder viewport is formed in the second feeding hopper; the second feeding hopper is connected with a machine barrel of the screw extruder; and the material quantity in the machine barrel can be observed in real time through the remainder viewport. The waste plastic pelleting unit transmits material through the transmission auger to realize uniform feeding and ensure that the obtained finished plastic product is high in quality.

Owner:绵阳立新科技发展有限公司

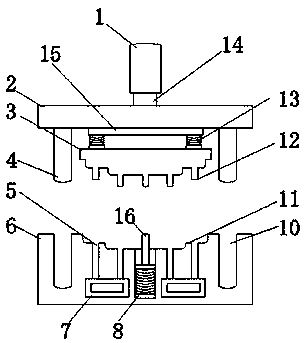

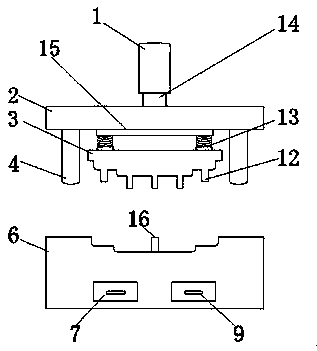

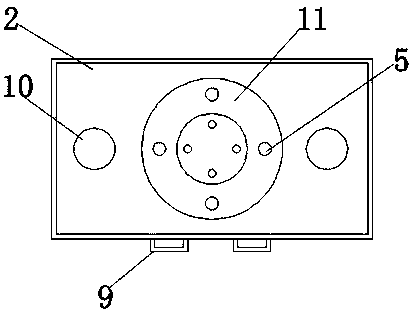

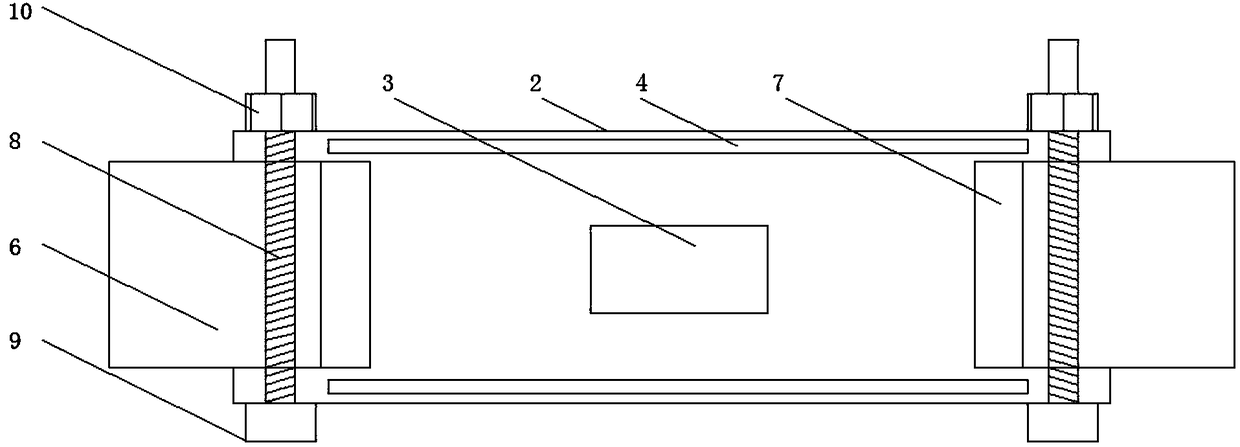

Glass punching device facilitating positioning and processing

InactiveCN110733131AReliable positioning and clampingReliable drillingWorking accessoriesStone-like material working toolsPunchingElectric machinery

The invention discloses a glass punching device facilitating positioning and processing. The glass punching device comprises a base box, wherein a lower positioning seat is fixedly installed at the middle position of the base box, an inner shell with an integrated structure is arranged in an inner cavity of the lower positioning seat, a drill rod is inserted into an inner cavity of the inner shell, the rod end, extending downwards into the interior of the base box, of the drill rod is connected with an electric telescopic rod, and the electric telescopic rod is fixedly installed at an output shaft end of a punching motor; and an upper positioning seat is arranged right above the lower positioning seat in a correspondence mode, an upper positioning column and a lower positioning column aresymmetrically arranged on the left side and the right side of the upper positioning seat, an upper positioning column and a lower positioning column are symmetrically arranged on the left side and theright side of the lower positioning seat, the lower end of each upper positioning column and the top end of each lower positioning column are assembled with one ends of support columns, and the otherends of the supporting columns abut rubber blocks. By the adoption of the technical scheme, drilling of a glass part is stable and reliable, a drilling glass can be prevented from being broken, the operation is convenient, and the punching production efficiency is improved.

Owner:蚌埠市谊诚重型机械制造有限公司

Cutting machine

InactiveCN105328271AExpand the cutting rangeAdjust the cutting direction at willPositioning apparatusMaintainance and safety accessoriesWorking environmentElectric machinery

The invention discloses a cutting machine, and relates to the field of machinery. The cutting machine comprises a base, wheels, a motor, a control mechanism, a vertical sliding rail, sliding blocks, a connecting block, a rotating plate, an upper cover, a cutter blade, a horizontal sliding rail, magnets and an accommodating space. The wheels are arranged at the two ends of the base. The motor is arranged inside the base. The upper cover and the cutter blade form a cutting tool which is arranged on the rotating plate. The rotating plate is connected with the sliding blocks through the connecting block. The sliding blocks are connected with the vertical sliding rail and are further arranged below the vertical sliding rail, and the vertical sliding rail is connected with the horizontal sliding rail through the sliding blocks. The horizontal sliding rail and the control mechanism are both arranged on the base. The control mechanism is located at the left end of the vertical sliding rail. The accommodating space is arranged at the right end of the base. The magnets are arranged on the vertical surface of the right end of the accommodating space. The cutting machine has the beneficial effects that the cutting direction can be adjusted freely, comprehensive cutting is convenient, the cutting efficiency is high, and the cut metal debris can be collected in a concentrated mode, so that the working environment for cutting is clean and tidy.

Owner:吕萍华

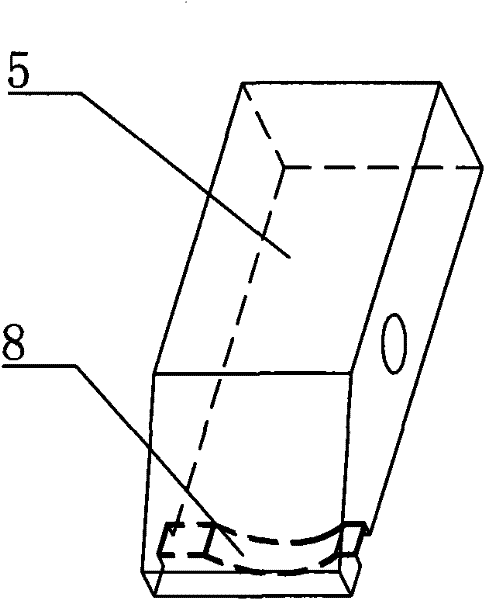

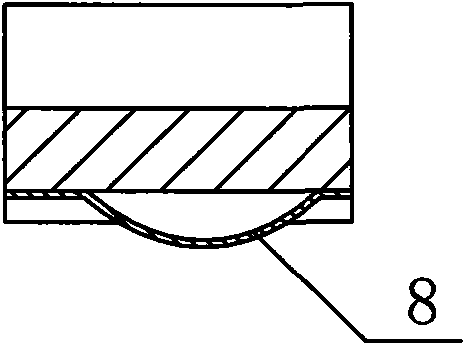

Die for automobile brake disc

PendingCN109127867AIncrease manufacturing costThe working environment is clean and tidyEjection devicesEngineeringHigh pressure

The invention discloses a die for an automobile brake disc. The die for the automobile brake disc comprises a hydraulic cylinder and a lower die base. The output end of the hydraulic cylinder is movably connected with a hydraulic rod, a mounting plate is fixed at the tail end, away from the hydraulic cylinder, of the hydraulic rod, a cushion plate is fixed on the bottom of the mounting plate, second springs are welded on both sides of the bottom of the cushion plate, the cushion plate is connected with an upper die through a second spring, the bottom of the upper die is equidistantly providedwith punching needles, a lower die slot is arranged in the center position of the top of the lower die base, the surface of the lower die slot is provided with punching holes matched with the punchingneedles, and a first spring is welded at the center position inside the lower die base. According to the invention, when the upper die makes contact with the lower die slot through the second spring,a function of cushioning pressure is fulfilled, the direct high-pressure impact on the processing raw material is avoided, and the punching holes communicate with a material box, so that the flushedwaste can directly fall into the material box through the punching holes.

Owner:郑琪

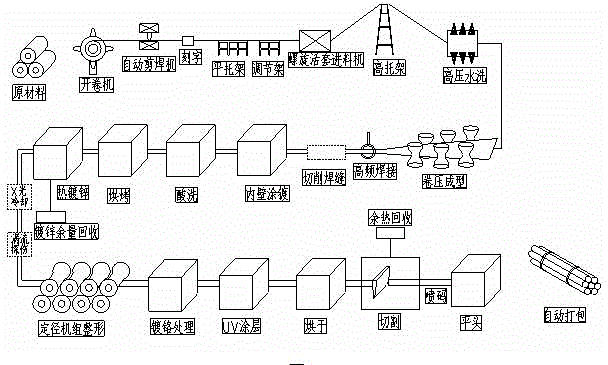

Online continuous plating process

An online continuous plating process comprises placing a raw material black steel belt on an uncoiling machine, shearing an initial portion of the steel belt through an automatic shear welding machine, performing lettering, performing adjustment through a flat supporting frame and an adjustment frame, entering a spiral loop feeding machine to perform adjustment control on the feeding speed and performing high pressure water washing, rolling pressure forming and high frequency welding after passing through a high supporting frame; cutting protruding welds which are formed at the welding position; removing the residual water on the inner wall of a steel pipe through an air cutter, enabling zinc-rich paint to uniformly coat the inner wall of the steel pipe through a spraying gun, performing pickling and preheating and simultaneously baking the zinc-rich paint in the steel pipe; immersing the liquid zinc to the outer surface of the steel pipe through a zinc pump to form the zinc bonding, performing X-ray cooling, performing an online eddy current inspection test, flowing into a sizing unit to shape, performing chrome plating treatment, performing a UV (Ultra Violet) coating process, performing drying and cutting, performing end chamfering end-flatting and inkjet coding and performing automatic packaging. According to the online continuous plating process, the online continuous pipe production and zinc plating is adopted and accordingly the production efficiency can be improved, the labor cost is reduced, the product flexibility is high, and the product competitiveness is improved.

Owner:HUNAN ADTO IND GRP

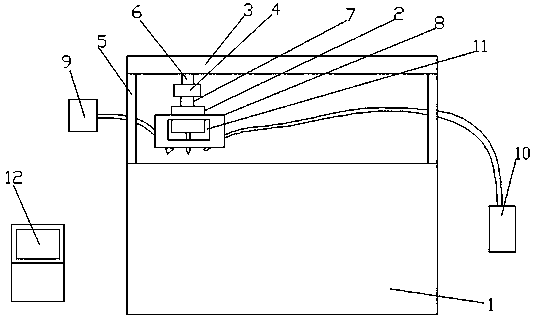

Timed automatic cleaning and water recovery circulatory system

InactiveCN103272793APrevent splashThe working environment is clean and tidyCleaning using liquidsWater sourceThermal insulation

The invention provides a timed automatic cleaning and water recovery circulatory system which is used for solving the technical problems that time, labor and water resource are wasted in cleaning a forming machine which is used for producing a thermal-insulation and decoration integrated plate. According to the technical scheme, a high-pressure pump is connected with a control unit, a shower pipe is arranged above a conveyor of the forming machine by means of a support, a high-pressure shower nozzle is arranged on the shower pipe, a stop valve which is connected with the control unit is arranged on the high-pressure shower nozzle, a sludge treatment port and a water outlet are formed in a setting pond, the high-pressure pump is communicated with the water outlet, the high-pressure pump is started every 10-40min under the control of the control unit, the control unit sends out a control signal to start the stop valve at the same time, water in the setting pond is sprayed out by the high-pressure shower nozzle, the forming machine is cleaned with the water, and the water flows back to the setting pond and is precipitated after the forming machine is cleaned with water. The timed automatic cleaning and water recovery circulatory system has the advantages that the forming machine is cleaned every 10-40min, the automatic operation is convenient and fast, man power and material sources are saved, water in the setting pond can be used circularly, and the water source is saved.

Owner:牛智勇

A dust collection and treatment device

ActiveCN106140771BEasy to disassemble and maintainEasy to moveDirt cleaningWater levelWaste management

The invention relates to a dust collecting and treating device. The dust collecting and treating device is characterized by comprising a collecting tank. A water level setting line is arranged in the colleting tank. A dust collecting opening is formed in the top of the collecting tank. A dust collecting and balancing device is arranged in the collecting tank. Wheels are arranged at the bottom of the collecting tank. A dust guide groove is formed in the inner wall of the collecting tank. During use, dust collecting liquid accounting for 1 / 3 of the volume of the collecting tank is loaded into the collecting tank, and accordingly dust can be absorbed sufficiently and dust can be prevented from overflowing and flying off. The dust collecting and balancing device guarantees that the dust entering the collecting tank does not pile up in the middle of the collecting tank, the dust evenly slides towards the periphery of the collecting tank along a collecting hood, the dust can be dissolved in water favorably, and even dust storage is benefited. A top cover plate is provided with an observation hole, the water level condition in the collecting tank can be observed, and a user can judge that the collecting tank is full and needs to be cleaned when the water level reaches a certain height.

Owner:TAOPU SEWAGE TRAEATMENT PLANT OF SHANGHAI CHENGTOU SEWAGE TREATMENT

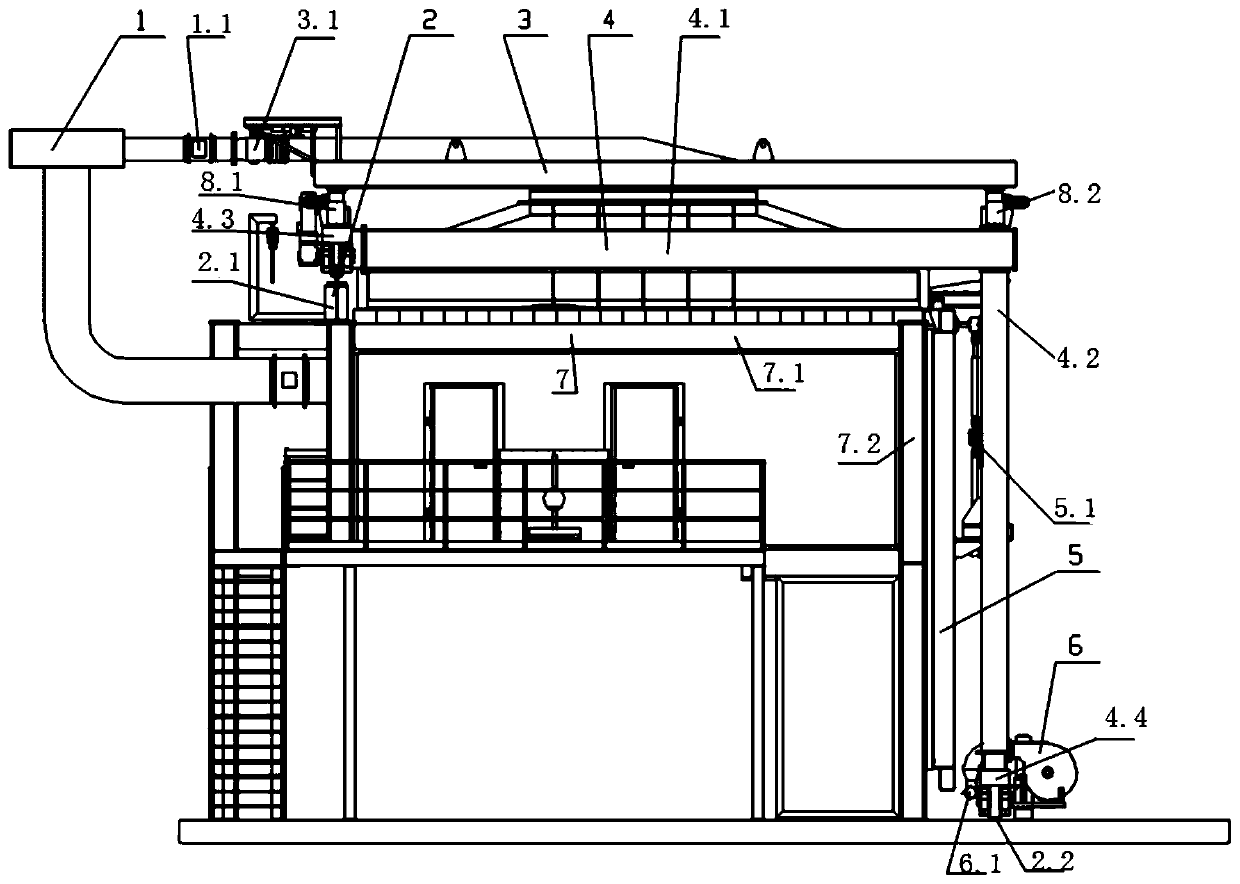

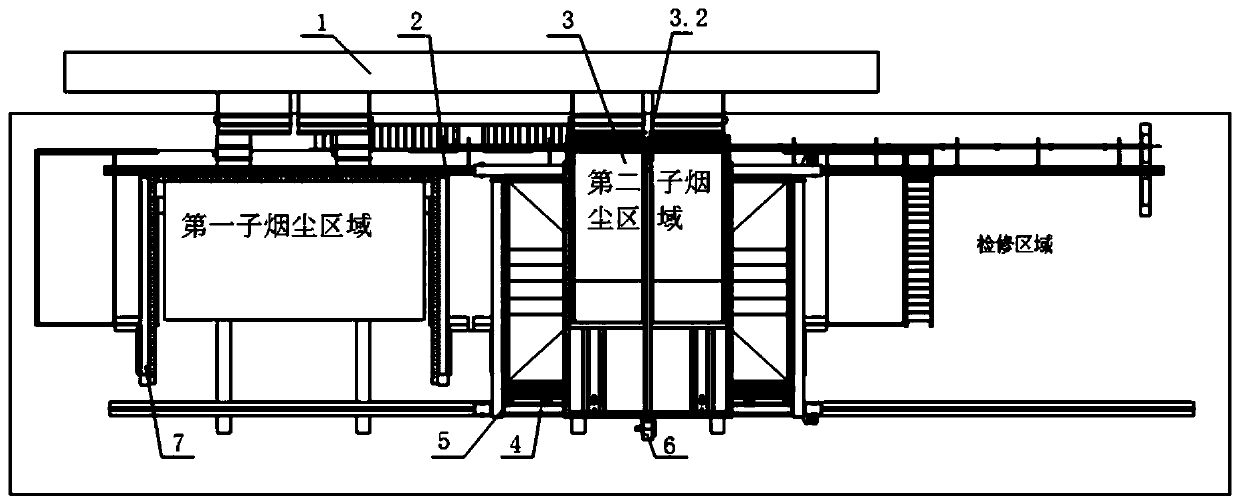

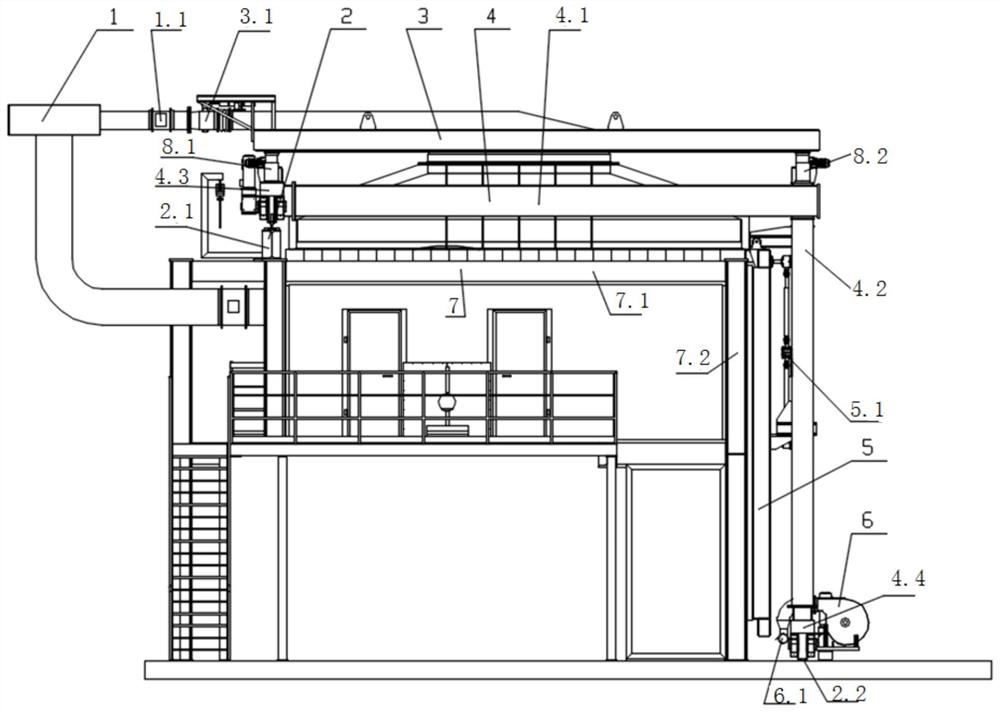

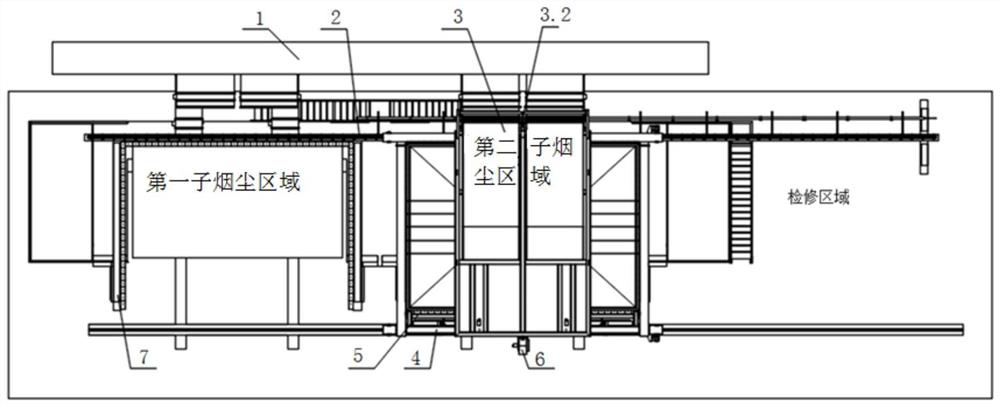

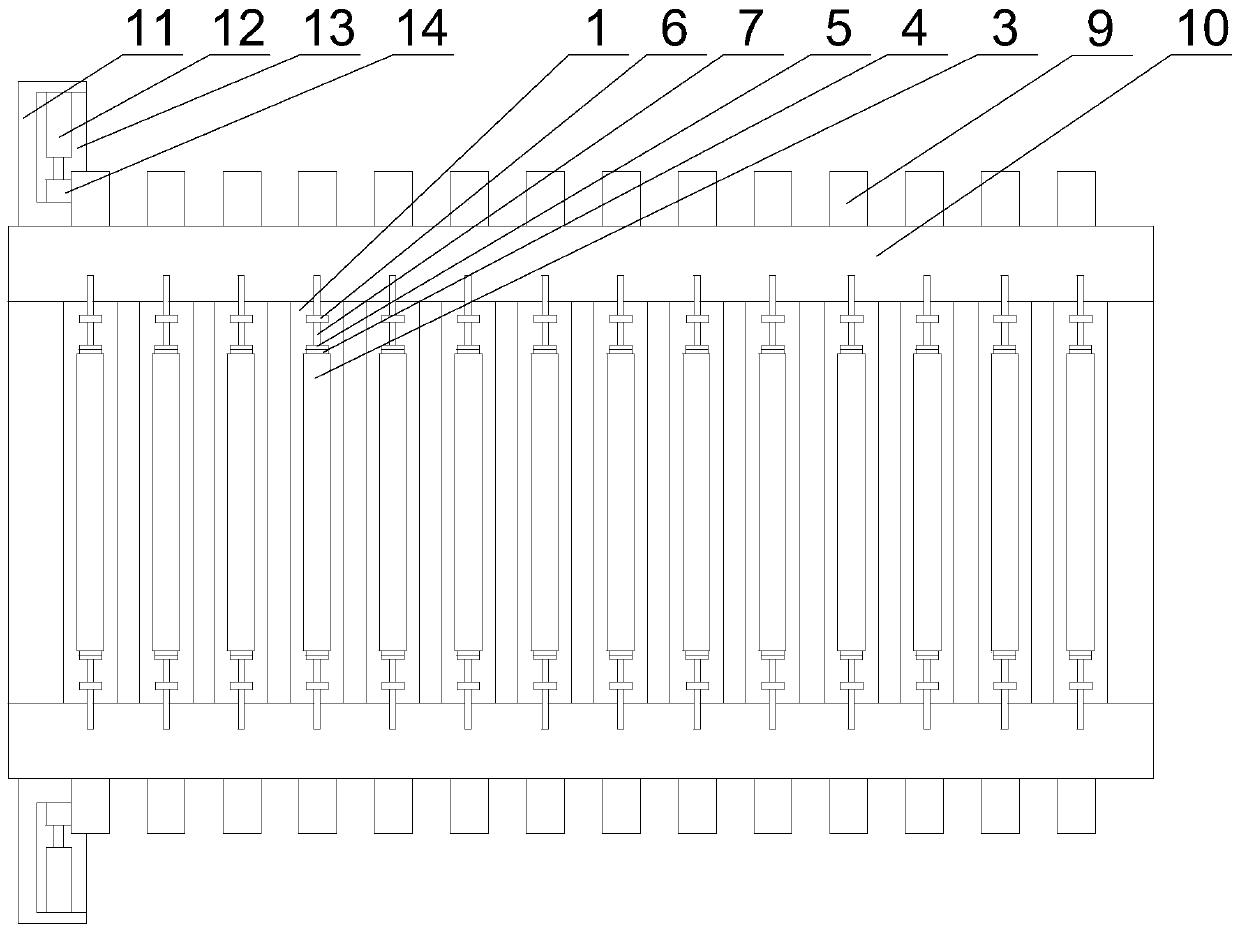

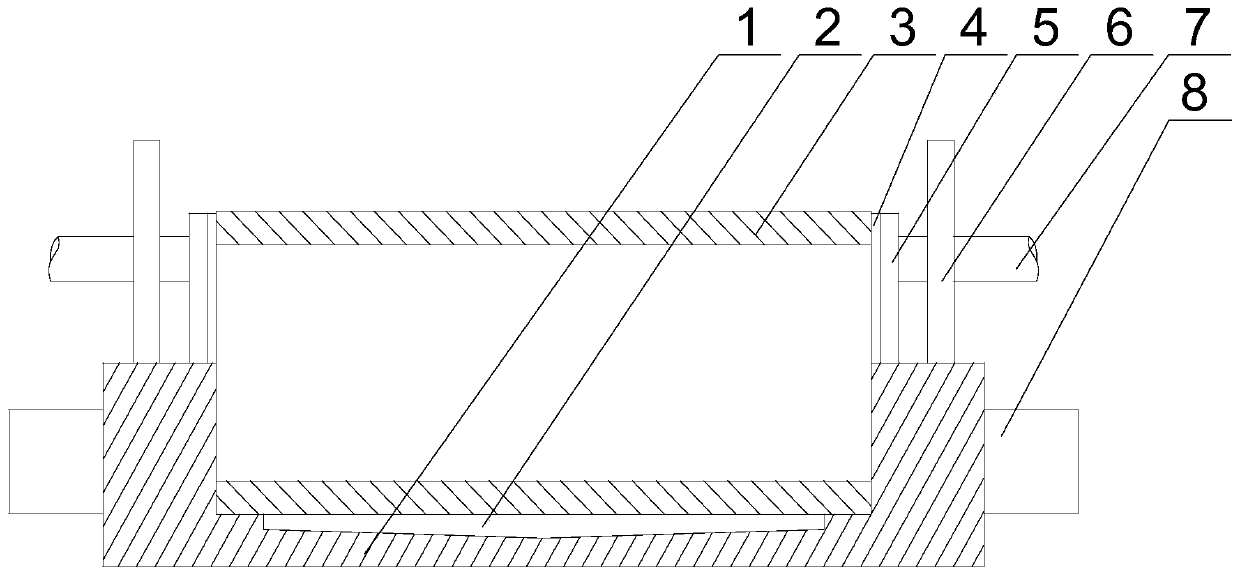

Movable type tundish tipping table dedusting device and dedusting method adopting same

ActiveCN111375750AExtended service lifeLow costMelt-holding vesselsDirt cleaningEngineeringDust abatement

The invention provides a movable type tundish tipping table dedusting device and a dedusting method adopting the same. The movable type tundish tipping table dedusting device comprises a fixed frame,a fixed pipeline, a rail, an L shaped vehicle body, a lifting cover and a lifting driving mechanism, wherein the fixed frame is divided along a smoke dust area into at least two sub smoke dust areas,openings are formed in the upper ends of the two sub smoke dust areas, and lateral openings are formed in the same side of the lateral direction of the two sub smoke dust areas; the fixed pipeline communicates with an induced draft fan; the rail is arranged on the fixed frame; the L shaped vehicle body comprises a horizontal beam and a vertical beam; the horizontal beam can move and is arranged onthe rail; the vertical beam is used for mounting a movable door and is also used for a movable door driving mechanism for driving the movable door to move; the lifting cover is arranged above the L shaped vehicle body and is provided with a structure fitting the upper end openings of the sub smoke dust areas and a movable ventilating pipeline communicating with the fixed pipeline; and the liftingdriving mechanism is connected between the lifting cover and the L shaped vehicle body and drives the lifting cover to move up and down. According to the movable type tundish tipping table dedustingdevice, smoke dust can be sucked to a dust remover for unified and centralized treatment without being dispersed into a working space.

Owner:北京中冶设备研究设计总院有限公司

Cutting machine

InactiveCN105945359AExpand the cutting rangeAdjust the cutting direction at willMaintainance and safety accessoriesWorking environmentEngineering

The invention discloses a cutting machine and relates to the field of machinery. The cutting machine comprises a base, wheels, a motor, a control mechanism, a vertical slide rail, a sliding block, a connection block, a rotating disk, an upper cover, a blade, a horizontal slide rail, magnets and an accommodating space. The wheels are arranged at the two ends of the base; the motor is arranged in the base; the upper cover and the blade compose a cutting tool arranged on the rotating disk; the rotating disk is connected with the sliding block through the connection block; the sliding block is connected with the vertical slide rail and arranged on the lower portion of the vertical slide rail; the vertical slide rail is connected with the horizontal slide rail through the sliding block; the horizontal slide rail and the control mechanism are both arranged on the base; the control mechanism is arranged at the left end of the vertical slide rail; the accommodating space is arranged at the right end of the base; and the magnets are arranged on a vertical face at the right end of the accommodating space. The cutting machine has the beneficial effects that the cutting direction can be randomly adjusted, omnibearing cutting is convenient, the cutting efficiency is high, cut-off metal chippings can be intensively collected, and the working environment for cutting is clean and tidy.

Owner:张志峰

Part machining device

InactiveCN108311893AAchieve the effect of saving energy and reducing consumptionAchieve a neat and clean effectOther manufacturing equipments/toolsWorking environmentGrinding process

The invention discloses a part machining device comprising a rectangular frame and a part body. The inner side wall of the rectangular frame is fixedly connected with the part body; the side, away from the part body, of the inner side wall of the rectangular frame is fixedly connected with an air cylinder; a moving rod moves to push a sleeve to downwards move, the sleeve moves to enable a first hinging rod to push a second sliding block through a recovering groove to move away from the part body, the recovering groove rotates under the effect of a second hinging rod, a moving box downwards moves to enable a cutting tool and grinding stone to get close to the part body, a motor works to enable a first rotating rod to rotate, thus the cutting tool and the grinding stone rotate to cut and grind the part body sequentially, therefore, according to the part machining device, the effects of energy saving and consumption reduction are achieved by means of the method that the cutting and grinding process can be completed at a time, and the effects of tidiness and cleanliness of the work environment can also be achieved.

Owner:潘建明

Cutting machine

InactiveCN106239231AExpand the cutting rangeAdjust the cutting direction at willFeeding apparatusMaintainance and safety accessoriesWorking environmentAgricultural engineering

The invention discloses a cutting machine and relates to the field of machinery. The cutting machine comprises a base, vehicle wheels, a motor, a control mechanism, a vertical slide rail, slide blocks, a connection block, a rotating disc, an upper cover, a blade, a horizontal slide rail, magnets and a containing space. The vehicle wheels are arranged at the two ends of the base. The motor is arranged in the base. The upper cover and the blade constitute a cutting tool. The cutting tool is arranged on the rotating disc. The rotating disc is connected with the corresponding slide block through the connection block. The corresponding slide block is connected with the vertical slide rail. Another slide block is arranged below the vertical slide rail, and the vertical slide rail is connected with the horizontal slide rail through the corresponding slide block. The horizontal slide rail and the control mechanism are both arranged on the base. The control mechanism is arranged at the left end of the vertical slide rail. The containing space is formed in the right end of the base. The magnets are arranged on the vertical face of the right end of the containing space. The cutting machine has the beneficial effects that the cutting direction can be adjusted at will; all-dimensional cutting can be conducted conveniently; cutting efficiency is high; metal chippings obtained after cutting can be collected in a centralized manner; and the cutting work environment can be tidy and clean.

Owner:洪义英

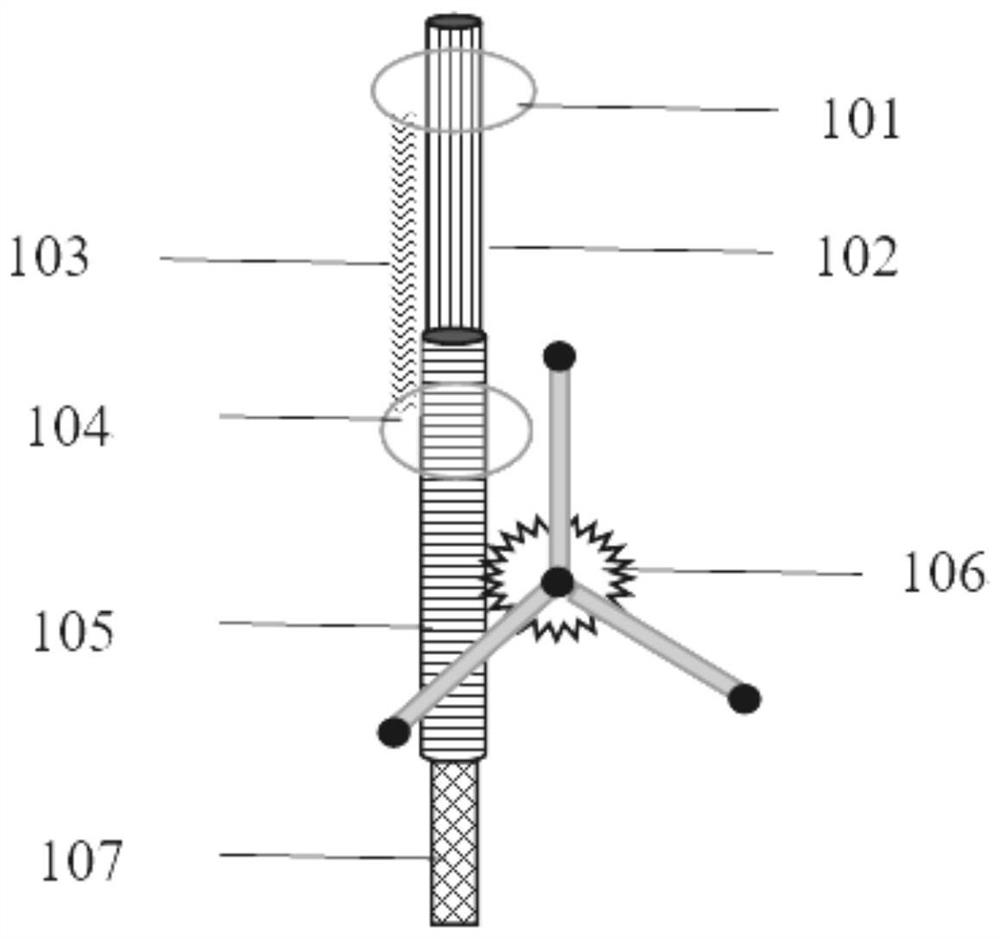

Multi-angle anisotropic medium experimental rock sample drilling device

ActiveCN112045866AEnable internal lubrication samplingImprove sampling success rateWithdrawing sample devicesWorking accessoriesThermodynamicsEngineering

The invention discloses a multi-angle anisotropic medium experiment rock sample drilling device. The device comprises a drilling machine base, a supporting assembly, a drill bit assembly, a power assembly, a lubricating assembly and a clamping assembly. The supporting assembly and the clamping assembly are arranged on the drilling machine base, and the power assembly is arranged at the upper end of the supporting assembly; the drill bit assembly is connected with the power assembly; the lubricating assembly comprises a lubricant box, the drill bit assembly comprises a drill bit power transmission shaft and a hollow sampling drill bit, the drill bit power transmission shaft is a hollow shaft, and the top of the drill bit power transmission shaft communicates with a lubricant control switch;the drill bit power transmission shaft is driven by the power assembly to rotate; and the hollow sampling drill bit is arranged at the lower end of the drill bit power transmission shaft, and the interior of the hollow sampling drill bit communicates with an inner cavity of the drill bit power transmission shaft. Lubricant in the lubricant box above a drilling machine is transferred into the drill bit through the hollow power transmission shaft, internal lubrication is achieved, and corresponding lubricant can be used for different lithologic rock samples.

Owner:PETROCHINA CO LTD

Drilling method for mother board of circuit board

InactiveCN113141717AResolve the breakImprove cooling efficiencyInsulating layers/substrates workingCleaning processes and apparatusChemical reactionThermodynamics

The invention discloses a drilling method for a mother board of a circuit board. According to the method, after drilling is completed every time, drilling dirt can be more effectively discharged out of the hole, the hole blocking phenomenon caused by excessive accumulation of the drilling dirt is avoided, the heat dissipation efficiency of the inner-layer thick copper drill hole can be improved, the bad problems that the roughness in the hole is too large due to too large heat and the like are solved, and meanwhile the problem that a drill point is broken is solved; the tool retracting speed is correspondingly reduced to 320 mm / s, so that the smoothness of the wall of the drilled hole is improved; a segmented drilling method which is the same as a back drilling method is adopted, so that the heat dissipation efficiency of drilling is effectively improved; in the plasma chemical reaction, particles playing a chemical role are mainly positive ion and free radical particles, the effect on different materials is uniform, and the drilling dirt removing effect is good. Through testing, the working environment in the drilling process is clean and tidy, stains are reduced, and the tidiness in the mother board drilling process is improved.

Owner:丰顺县和生电子有限公司

Corn thresher with washing function

ActiveCN106717587AEasy to adjustControl the depth of threshingThreshersFood treatmentEngineeringWater spray

The invention discloses a corn thresher with a washing function. The corn thresher with the washing function comprises a frame body and a threshing cylinder. The threshing cylinder is slantwise installed on the frame body. The threshing cylinder comprises parallelly-installed main roller and sub-roller. Two sides of the threshing cylinder are provided with baffles. A collecting groove is installed below the threshing cylinder. A bottom plate of the collecting groove is slantwise installed. One lower end of the bottom plate of the collecting groove is provided with a grain outlet. Two side walls opposite to the grain outlet are provided with sliding rails. A row of screw rods is connected between the sliding rails. A water spray pipe of which a water injection nozzle faces to the lower part is further installed above the grain outlet. An adjusting plate is further installed above the threshing cylinder. The adjusting plate is connected with the frame body on the bottom of the baffles by a spring. The upper surface of the adjusting plate is provided with an acting force control device. The adjusting plate, the baffles and the threshing cylinder form the inlet and the outlet of corn cobs. The inlet and the outlet of the corn cobs are respectively positioned at the higher end and the lower end of the threshing cylinder. The corn thresher with the washing function is capable of solving the problems that the corn thresher cannot separate the corn silks from the corn kernels, the corn thresher has not the washing function and the process is complicated while the threshing degree is adjusted.

Owner:宜良县东毅农机制造有限公司

A numerical control cutting device with good safety and protection

InactiveCN108890377ASimple structureEasy to useMaintainance and safety accessoriesNumerical controlEngineering

The invention discloses a numerical control cutting device with good safety protection, including CNC machines, displacement rails and cutting machines, the displacement rail comprises an X-axis displacement rail and a Y-axis displacement rail, the two ends of the X-axis displacement slide rail are correspondingly arranged on the two sides of the numerical control machine tool through brackets, Amovable block is arranged above the Y-axis displacement slide rail, the movable block is correspondingly arranged below the X-axis displacement slide rail, A drive pulley is correspondingly arranged on the top of the cutting machine, the drive pulley is correspondingly arranged below the Y-axis displacement slide rail, a protective cover shell is correspondingly arranged on the cutting machine, the protective cover shell is arranged in a hollow structure and the bottom part is an opening structure, and the top part of the protective cover shell is sleeved on the cutting machine body. The invention has the advantages of simple structure, convenient use, effectively avoiding splash phenomenon caused by cutting, and has a cooling and adsorption mechanism to ensure a relatively clean and tidyworking environment.

Owner:苏州捷捷威自动化装备有限公司

Energy-saving environmentally-friendly novel plastic processing device

The invention discloses an energy-saving environmentally-friendly novel plastic processing device. The device comprises a closed box body. The bottom of the closed box body is fixedly connected with asliding rail, and the middle of the sliding rail located inside the closed box body is provided with a worktable. The top surface of the worktable is provided with a horizontal hole, and the portionof the closed box body disposed at the bottom of the horizontal hole is provided with a waste collecting tank. A sliding block is mounted on the surface of the sliding rail. One side of the sliding block close to the worktable is provided with a half-opening groove. A moving motor is mounted on the top of the closed box body, and one side of the moving motor close to the middle top of the closed box body is connected to a moving rod by a coupling. The device relates to the technical field of plastic product processing devices. The device can conveniently collect the debris generated during theprocessing of workpieces through a collecting device, and the stability of the device is ensured by means of legs and suckers.

Owner:湖州吴兴旭诚塑料制品有限公司

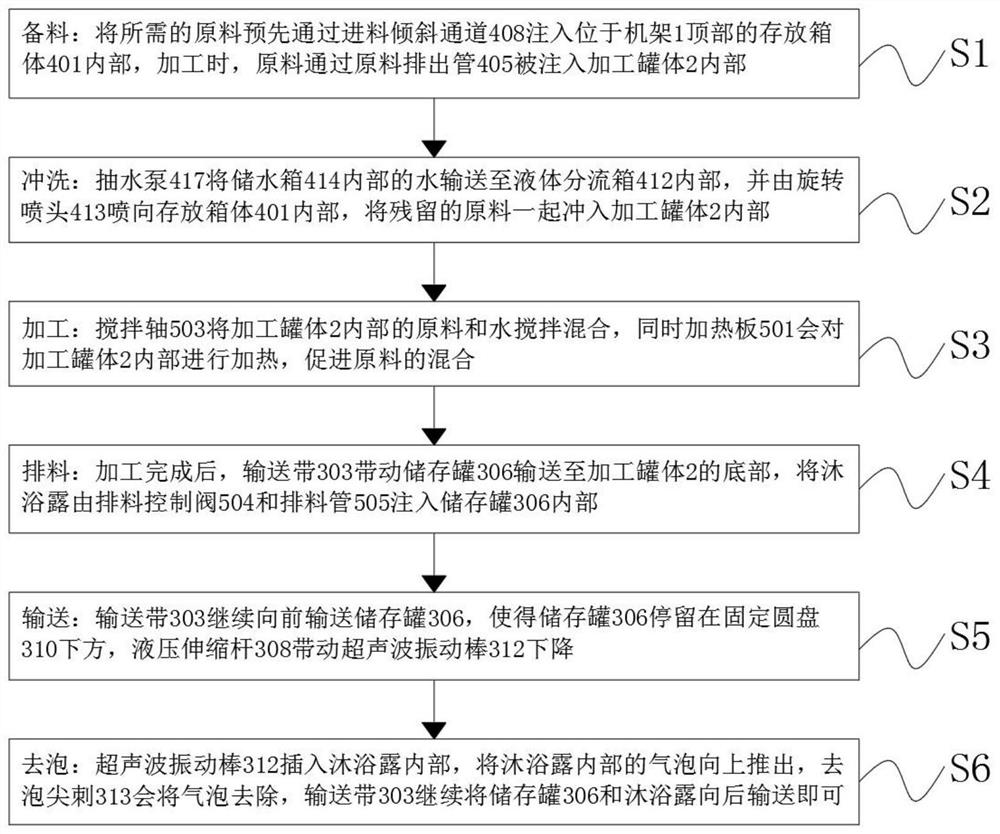

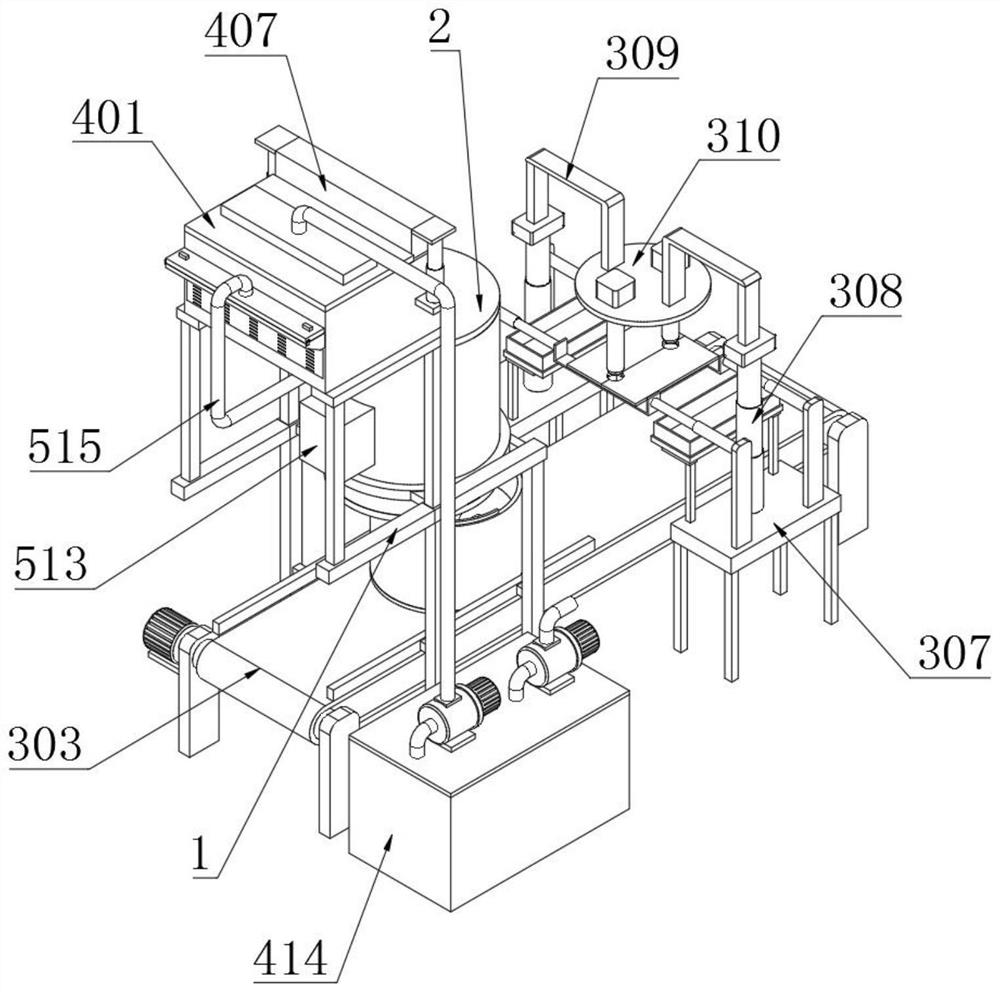

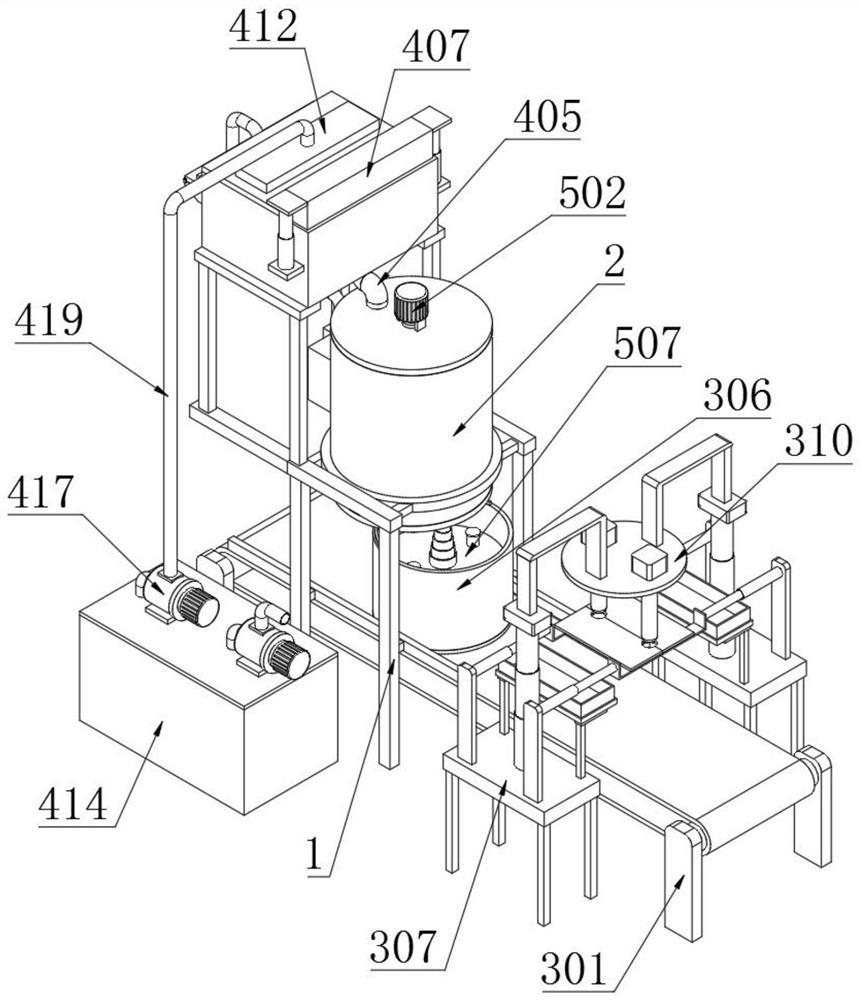

Shower gel containing natural plant components and preparation method thereof

ActiveCN113697752AScientific and reasonable structureEasy to useRotary stirring mixersHollow article cleaningShower gelEngineering

The invention discloses a preparation method of shower gel containing natural plant ingredients. The preparation method comprises the following steps that conveying is achieved: a storage tank is conveyed continuously forwards by a conveying belt, so that the storage tank stays below a fixing disc, and an ultrasonic vibration rod is driven to descend by a hydraulic telescopic rod. According to the preparation method of the shower gel containing the natural plant ingredients, after shower gel processing is finished, the shower gel is discharged and injected into the storage tank, the storage tank and the shower gel are conveyed backwards through a conveying shaft and the conveying belt, standing is needed for a certain time when shower gel processing is finished, and the interior of a processing tank can still keep a certain temperature by discharging the shower gel, heat in the storage tank cannot be lost, then a new raw material is injected to directly carry out next processing, the processing procedure of the shower gel can be continuously carried out, the waiting time of processing equipment is shortened, the working efficiency is improved, meanwhile, a positioning batten plays a role in positioning the storage tank, and it is ensured that the position of the storage tank cannot deviate in the conveying process.

Owner:亨特酒店用品(汕头)有限公司

Positioning device for automatically processing blades of push scissors for haircut

InactiveCN101623839BRealize automatic positioningSmooth transmissionOther manufacturing equipments/toolsWorking environment

The invention discloses a positioning device for automatically processing blades of a pair of push scissors for haircut, which is characterized by comprising a positioning base, a positioning pin and a press plate, wherein the press plate is axially connected to the positioning base, the back end of the press plate is provided with an elastic jacking device, a through hole is arranged on the positioning base, the positioning pin and the through hole are in sliding fit, and an automatic lifting drive device is connected to the positioning pin. The positioning device has the advantages that theautomatic positioning of the blades can be realized by the device; when a previous feeding procedure delivers the blades to the positioning base, the front end part of the press plate presses the blades in advance by the elasticity of a spring; when positioning holes on the blades are aligned with the through hole on the positioning base, a drive rod of a second air cylinder drives the positioning pin to raise upwards and penetrate into the positioning holes of the blades, then a jacking rod of a first air cylinder jacks upwards to drive the press plate to press the blades, and the positioning process is finished; the whole process has no need of artificially delivering the blades into the positioning device for positioning, the work efficiency is high, and the whole processing process can be carried out in a closed environment so that the working environment is clean and tidy.

Owner:王夏生

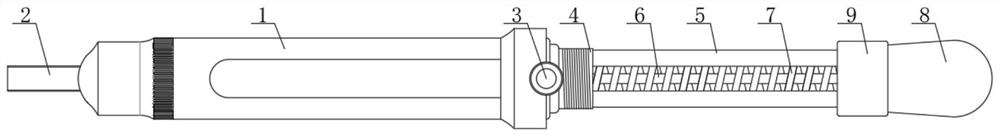

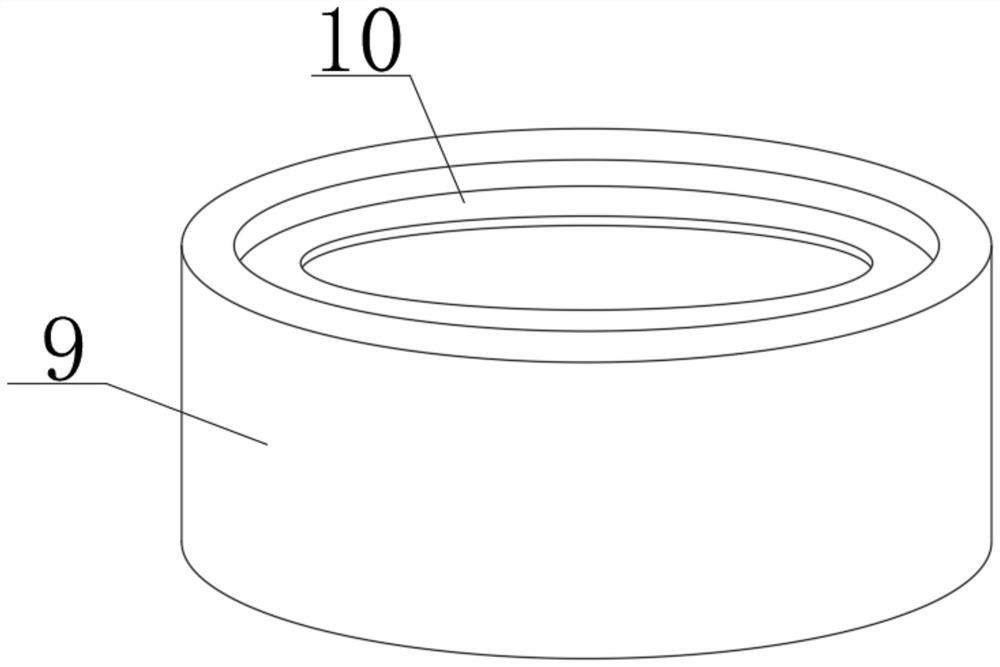

Solder sucker with protection mechanism

PendingCN113369631AShorten the lengthAvoid extrusion breakageSoldering auxillary devicesEngineeringStructural engineering

The invention provides a solder sucker with a protection mechanism. The solder sucker comprises a solder sucker body and a solder sucker nozzle, wherein one side of the solder sucker body is fixedly connected with the solder sucker nozzle, the front side of the solder sucker body is fixedly connected with a button, the interior of the solder sucker body is slidably connected with a spring arm, and supporting rods are arranged in the spring arm; and telescopic springs are arranged at the outer sides of the supporting rods correspondingly, the right side of spring arm is fixedly connected with an upper strength head, and the other side of the solder sucker body is fixedly connected with a threaded sleeve. According to the solder sucker, through the arrangement of the solder sucker nozzle, the button, the threaded sleeve, a rotating sleeve and a rotating ring, when a worker goes out to work, the fixing effect is achieved by extruding the upper strength head and enabling the rotating sleeve to be spirally connected with the threaded sleeve, at the moment, the length of the solder sucker can be shortened, and meanwhile the situation that the spring arm is extruded to be broken is effectively avoided, a good protection effect is achieved, and the service life is guaranteed.

Owner:LIAONING TECHNICAL UNIVERSITY

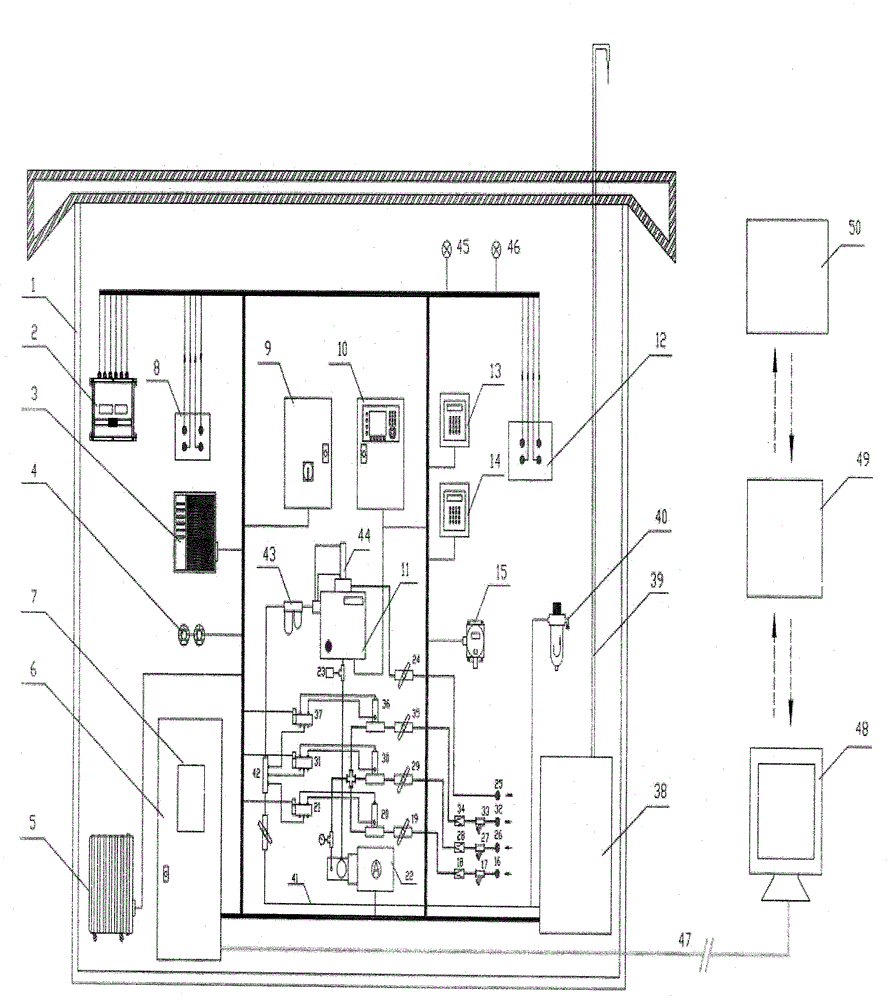

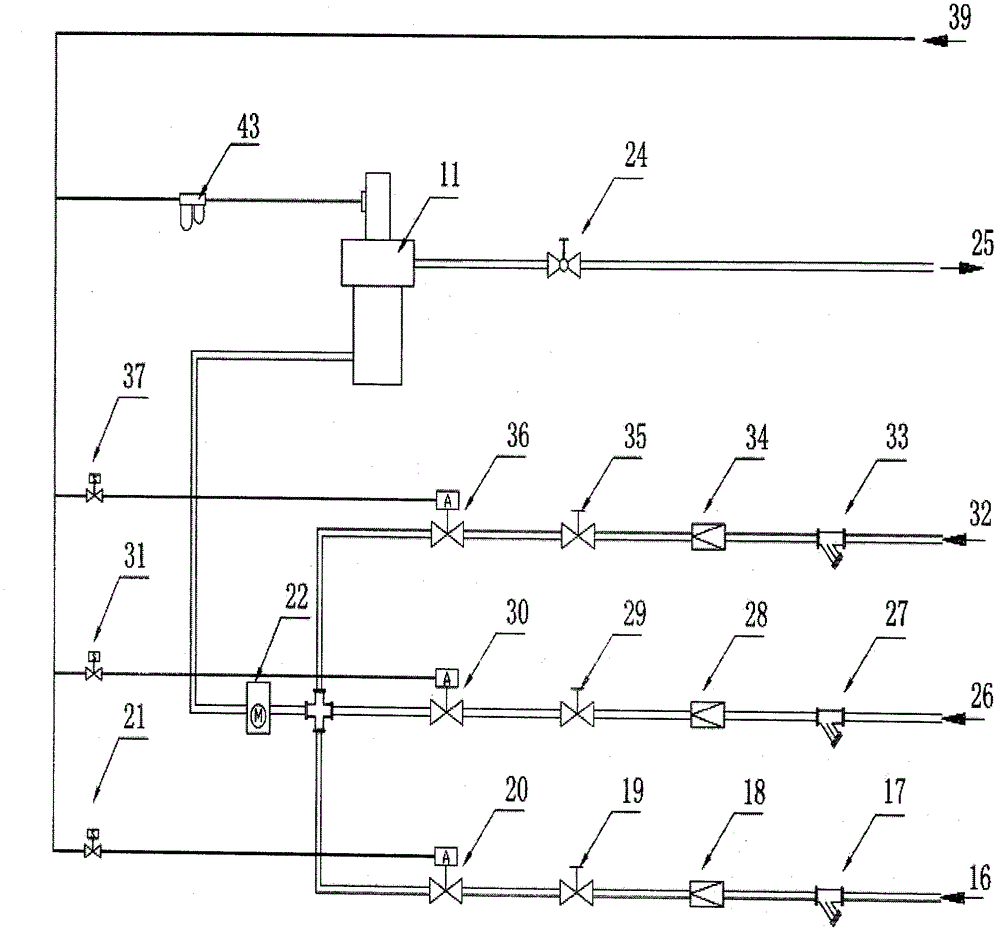

A new online monitoring system for oilfield produced water

ActiveCN102253176BEffective integrated positive pressure protectionThe working environment is clean and tidyTesting waterPositive pressureWater quality

The invention relates to a novel oil field produced water online monitoring system, which comprises online monitoring equipment with a non-explosionproof structure, wherein the monitoring equipment with the non-explosionproof structure is integrated highly to be arranged in a positive pressure explosionproof analytical cabin. In the online monitoring system, a sampling and pretreatment unit adopts three sampling points which are at an outlet of a setting tank, an outlet of a purification tank and an outlet of a clear water tank respectively; a water path switching and pneumatic control unit is realized by the programmable logic controller (PLC) programming control technology and the electromagnetic and pneumatic technology; data monitored by a monitoring analytical and data processing unit is collected by a PLC control cabinet and is connected with a station control upper computer, a station control server, a factory level information center and a digitalized command system platform of an oil field company sequentially by a recommendation standard 485 (RS485) bus signal; automation control is realized by the PLC programming technology; the self-cleaning and maintenance-free of a pipeline and measuring unit are realized by a double action mode of 'air purge and hydraulic pressure cleaning', so that water quality can be monitored continuously in real time and the running state of deoiling equipment or a filtering system can be monitored. The novel oil field produced water online monitoring system has the advantages that: the automaticity is high; the labor intensity of workers is relieved; the remote transmission of data is realized; and the like.

Owner:陕西睿海丽君环境科技有限公司

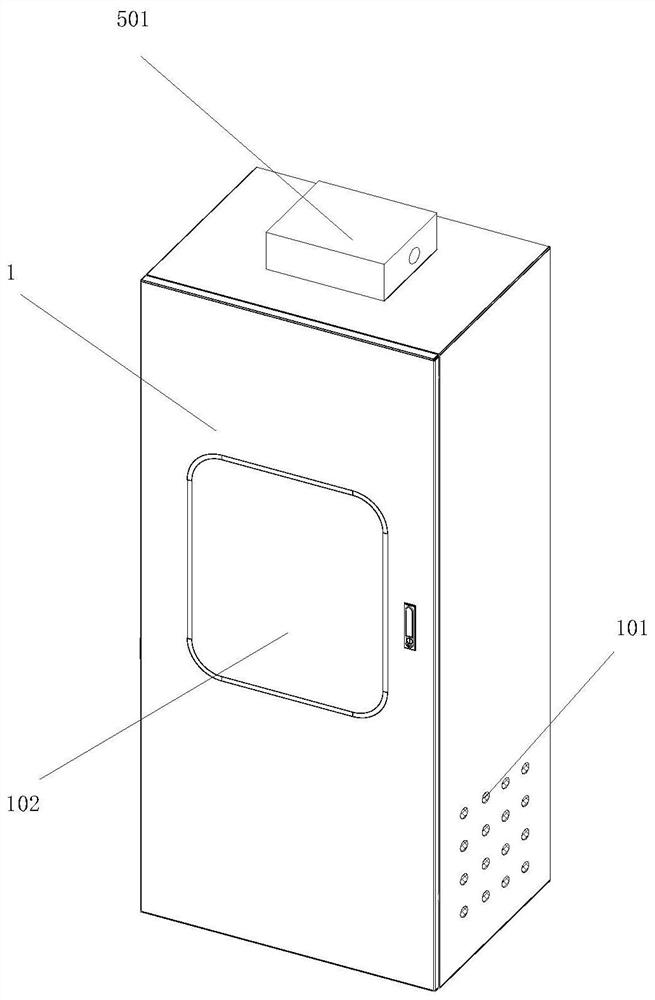

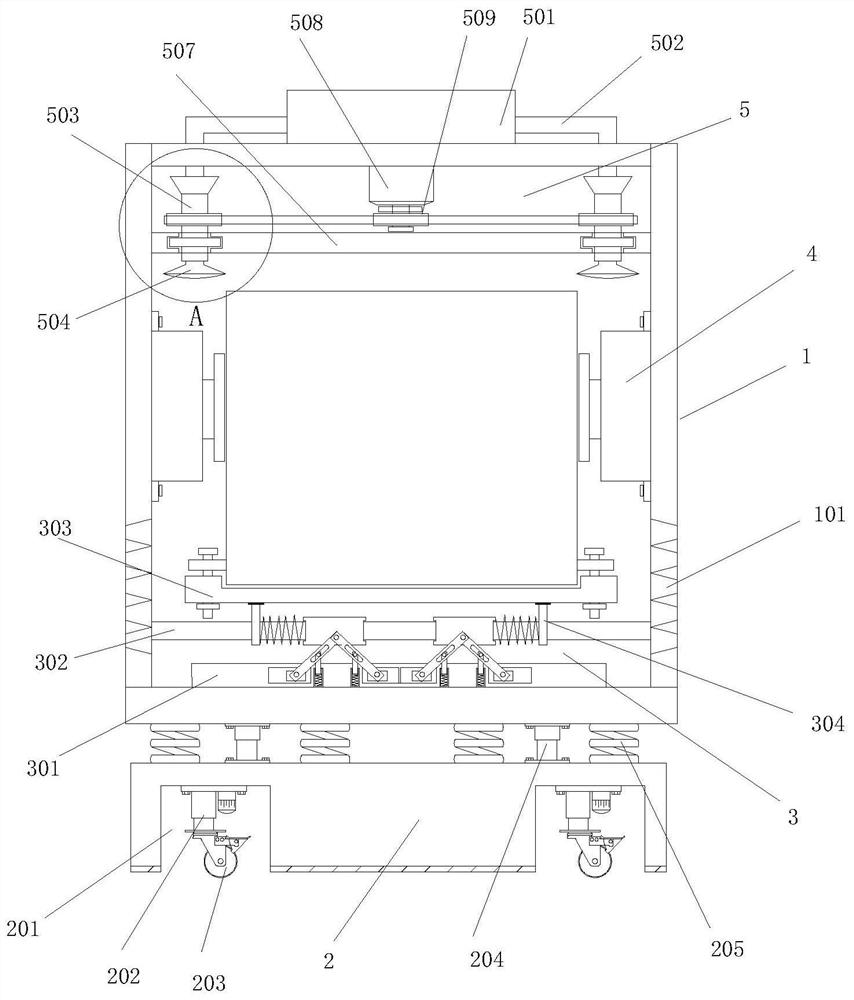

An intelligent noise reduction cabinet for servers

ActiveCN112739094BRealize shock and noise reductionImplement bufferingCasings/cabinets/drawers detailsVibration suppression adjustmentsElectric machineryEngineering

The invention discloses an intelligent noise-reducing cabinet for servers, which comprises a cabinet body, the cabinet body is fixedly erected on a base, server components are arranged inside the cabinet body, and the server components are fixedly arranged on a vertical On the noise frame, the interior of the cabinet body and the two sides of the server components are provided with horizontal noise reduction frames, the interior of the cabinet body and above the server components are provided with a heat dissipation chamber, and the interior top of the heat dissipation chamber is provided The motor drives the pulley through the belt to drive the connecting pipes on both sides of the heat dissipation chamber to rotate, so that the connecting pipe drives the shower-type air spray head to spirally supply air in the cabinet body, and the heat inside the cabinet body is sent out through the air outlet through the wind force to achieve air cooling. The heat dissipation treatment of the cabinet body, and the air outlet is set into a horn-shaped structure, which effectively prevents dust from entering the inside of the cabinet body and effectively prevents dust from adhering to server components.

Owner:ANHUI FEIKAI ELECTRONICS TECH CO LTD

Mechanical processing device with waste recovery device and mechanical processing method

InactiveCN108032135AAvoid safety accidentsReduce manufacturing costMeasurement/indication equipmentsMaintainance and safety accessoriesTransmission beltWorking environment

The invention discloses a mechanical processing device with a waste recovery device and a mechanical processing method. The mechanical processing device includes a device main supporting leg, a motorsupporting table, a material transporting motor, a transmission belt, an infrared locator, a locator moving groove and a locator limiting board. The infrared locator is installed above a material transporting table, the locator moving groove is installed above the infrared locator, a cutting processing room is installed below the locator limiting board, a cutting drive motor is installed below thecutting processing room, a waste recovery chamber is installed below the cutting drive motor, an operation control panel is installed on the outer side of the motor supporting table, and work indicating lamps are installed below the operation control panel. The mechanical processing device with the waste recovery device and the mechanical processing method have the advantages that waste generatedby mechanical processing can be recovered in the mechanical processing, not only can the occurrence of safety accidents be avoided, but also the waste can be uniformly processed, the production costis reduced, and the working environment is clean and tidy.

Owner:韩玲

Movable tundish tipping table dust removal device and dust removal method using same

ActiveCN111375750BExtended service lifeLow costMelt-holding vesselsDirt cleaningFixed frameControl theory

The invention provides a movable type tundish tipping table dust removal device and a dust removal method using the same. The device includes: a fixed frame, which is divided into at least two openings at the upper end along the smoke and dust area, and side openings on the same side. The sub-smoke and dust area; the fixed pipeline is connected with the induced draft fan; the track is arranged on the fixed frame; the L-shaped car body includes a horizontal beam and a vertical beam, the horizontal beam is movable, and is arranged on the track, and the vertical beam is used for To install the movable door, and the movable door driving mechanism used to drive the movable door to move; the lifting cover is arranged above the L-shaped vehicle body, the lifting cover has a structure that fits with the upper opening of the sub-smoke and dust area, and is connected with the fixed A mobile ventilation duct connected by pipelines; a lifting drive mechanism, connected between the lifting cover and the L-shaped vehicle body, drives the lifting cover to move up and down. The smoke and dust of the present invention can be sucked to the dust collector for unified and centralized treatment without spilling into the working space.

Owner:北京中冶设备研究设计总院有限公司

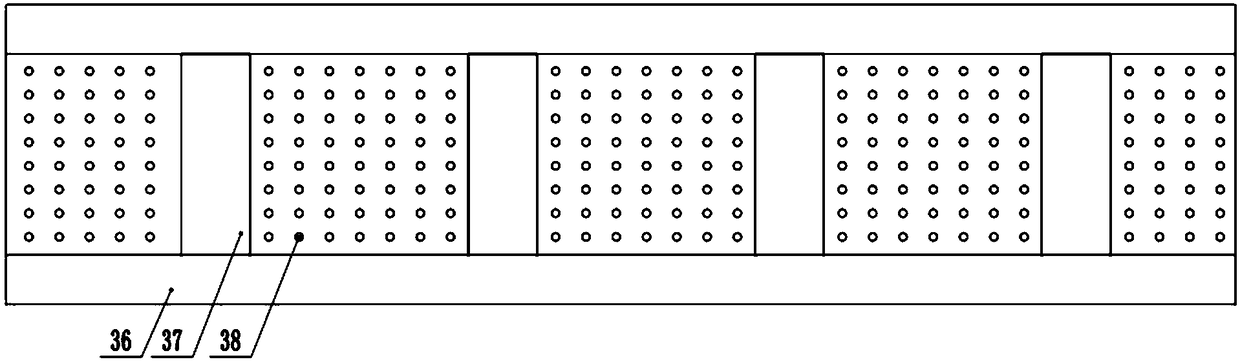

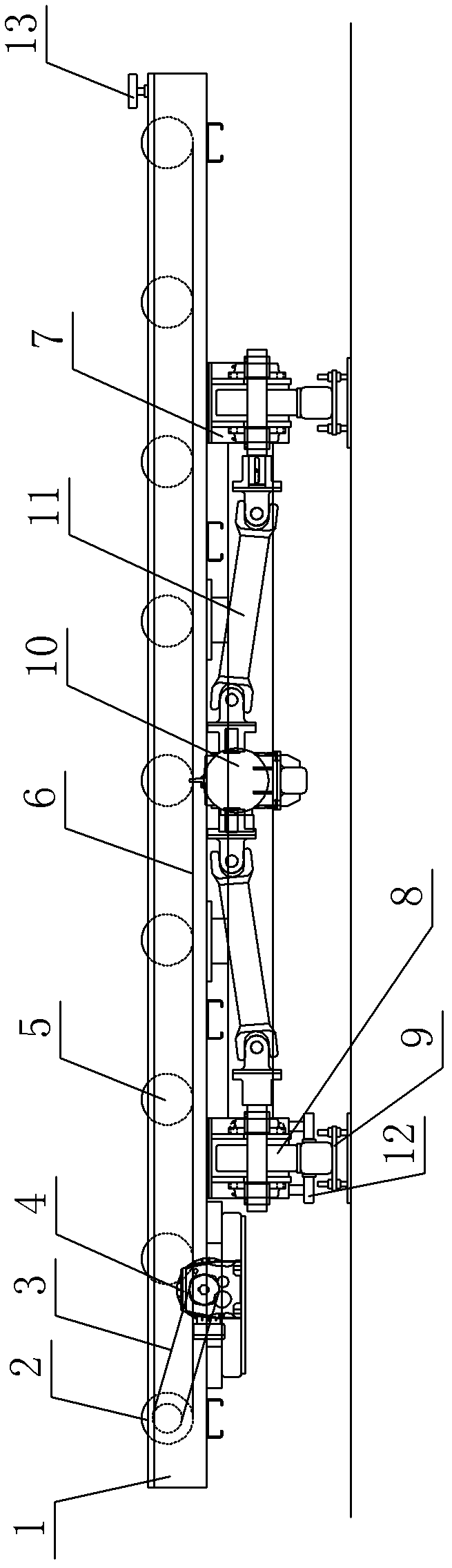

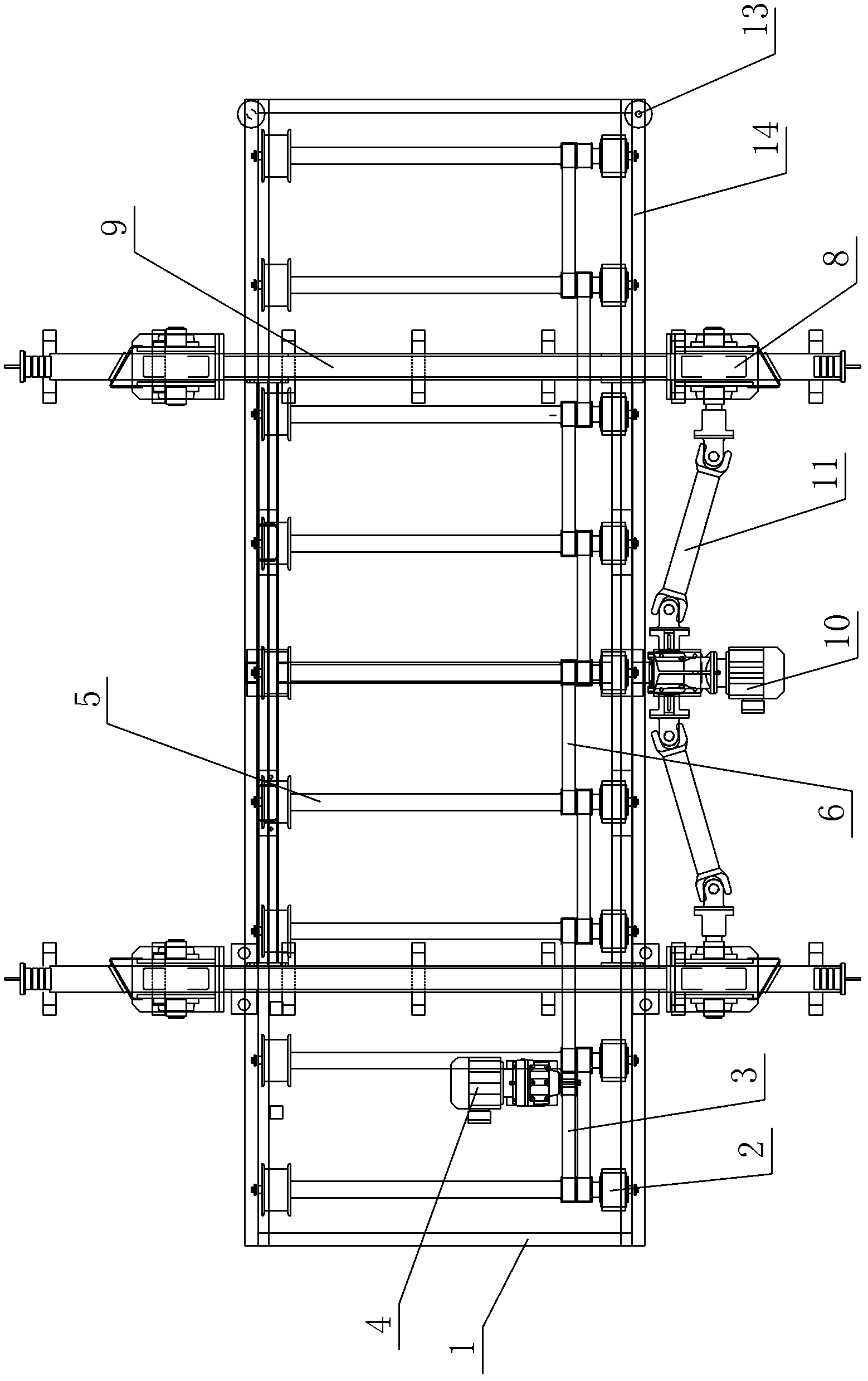

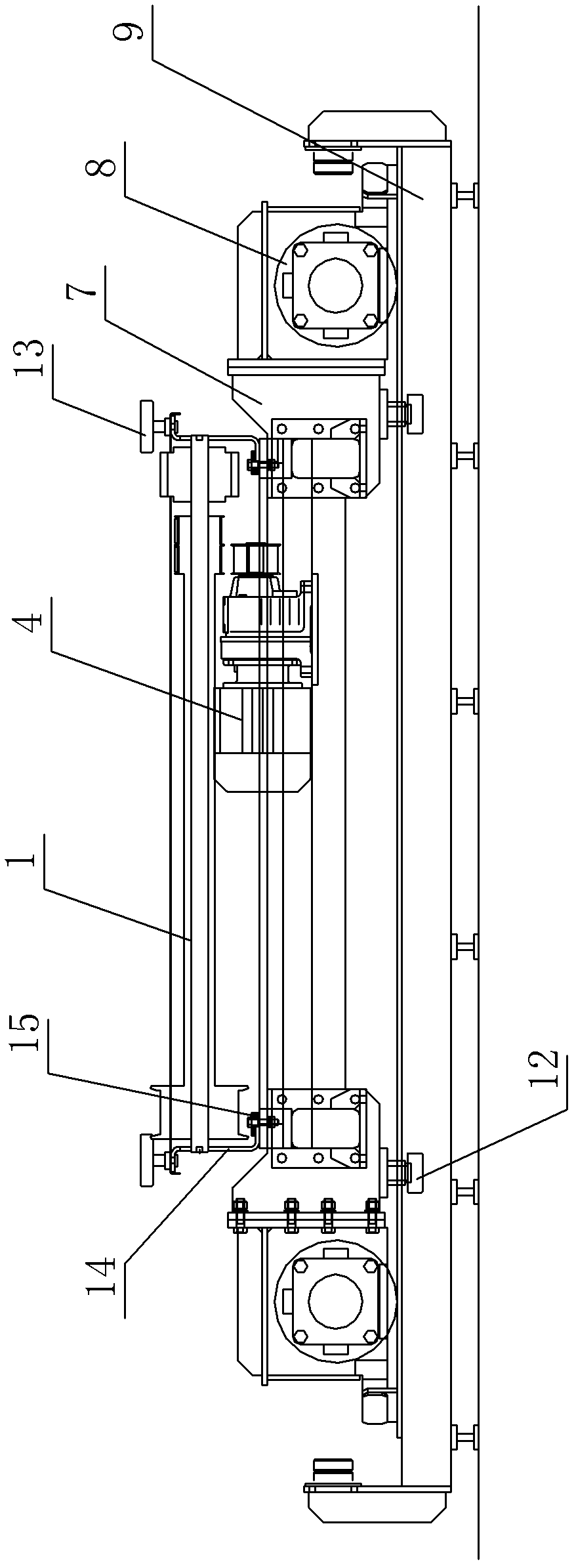

Conveyor system for electrothermal film element production line

ActiveCN107161595BAvoid breakingThe working environment is clean and tidyConveyor partsRoller-waysProduction lineTransfer system

The invention discloses a conveying system for an electrothermal film element production line. The conveying system comprises two transmission chains; a plurality of rollers are rotationally arranged between the two transmission chains, rotating shafts at the two ends of each roller movably penetrate through the transmission chains and then extend outwards, and transmission gears are installed on the rotating shafts; a rectangular groove is formed in the upper surface of each roller; and supporting seats are arranged on the side walls of the two transmission chains, vertically-placed air cylinders are fixed to the supporting seats, bottom plates are fixed to the output ends of the air cylinders, motors are fixed on the bottom plates, and the output ends of the motors are provided with main gears matched with the transmission gears. In the moving process of glass tubes, the rollers move smoothly, mutual interference does not occur between every two adjacent glass tubes, and the residues attached to the outer walls of the glass tubes directly fall into the rectangular grooves after falling off and do not cause any pollution to the working environment of the production line.

Owner:CHENGDU YANGZHONG NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com