Corn thresher with washing function

A thresher and corn technology, applied in threshing equipment, agricultural machinery and implements, food processing and other directions, can solve the problems of cumbersome steps, no cleaning function, inability to separate corn silk and corn kernels, etc., and achieves a clean and tidy working environment. The effect of reducing work steps and protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

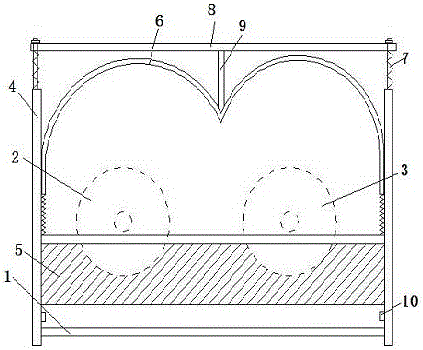

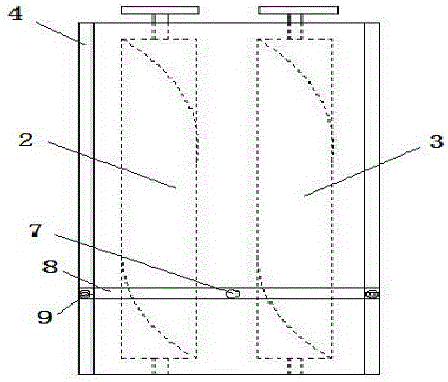

[0025] figure 1 and figure 2 A corn thresher with cleaning function is shown, including a frame body 1 and a threshing cylinder, the above-mentioned threshing cylinder is arranged on the frame body 1 obliquely, the threshing cylinder includes a positive cylinder 2 and a secondary cylinder 3 arranged side by side, the positive cylinder 2 The gap between it and the auxiliary drum 3 is smaller than the diameter of the corn to be processed. The two sides of the above-mentioned threshing drum are provided with baffles 4, and the bottom is provided with a collecting tank 5. The bottom plate of the collecting tank 5 is inclined, and the bottom end of the collecting tank is provided with a There is a grain outlet, slide rails are arranged on the opposite side walls of the grain outlet, a row of retaining screw rods are connected between the slide rails, and a water spray pipe is arranged above the grain outlet in the collecting tank 5, and the water spray of the water spray pipe The...

specific Embodiment 2

[0028] This embodiment further explains the structure of the force control device on the basis of specific embodiment 1. The above-mentioned force control device includes a pressing vertical bar 7, a pressing horizontal bar 8 and a spring support bar 9. The spring support bar 9 Including a threaded rod and a spring, the pressing vertical rod 7 is vertically arranged on the upper surface of the adjustment plate 6, the pressing cross bar 8 is arranged on the top of the pressing vertical rod 7 along the horizontal direction, and the above-mentioned threaded rod is arranged on the baffle plate 4 along the vertical direction The top of the threaded rod passes through the pressing cross bar 8 and is flexibly connected with the pressing cross bar 8, and the spring is passed through the threaded rod and is positioned under the pressing cross bar 8.

[0029]When adjusting the distance between the adjusting plate 6 and the threshing cylinder, you only need to adjust the position of the n...

specific Embodiment 3

[0031] The present invention adds a buffer plate on the basis of the specific embodiment 1. The above-mentioned corn cob outlet is provided with a buffer plate, and the buffer plate is movably connected with the adjustment plate 6 through a hinge.

[0032] Setting the buffer plate at the corn cob outlet can minimize the speed at which the corn cobs rush out from the corn cob outlet of the corn thresher with cleaning function, and can effectively prevent people from being injured by the corn cobs that are rushed out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com