Mechanical processing device with waste recovery device and mechanical processing method

A technology of mechanical processing and recycling devices, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as working environment impact, human injury, safety accidents, etc., to avoid safety accidents, work environment is clean and tidy, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

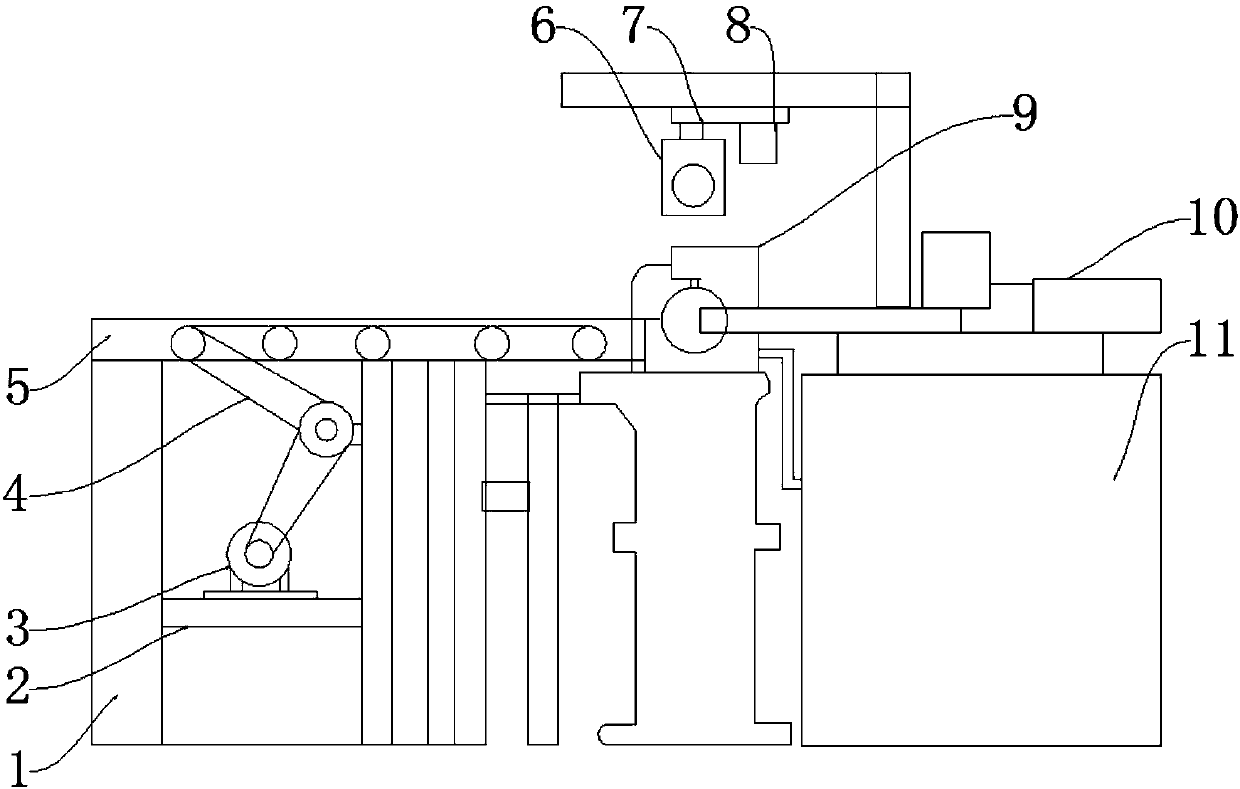

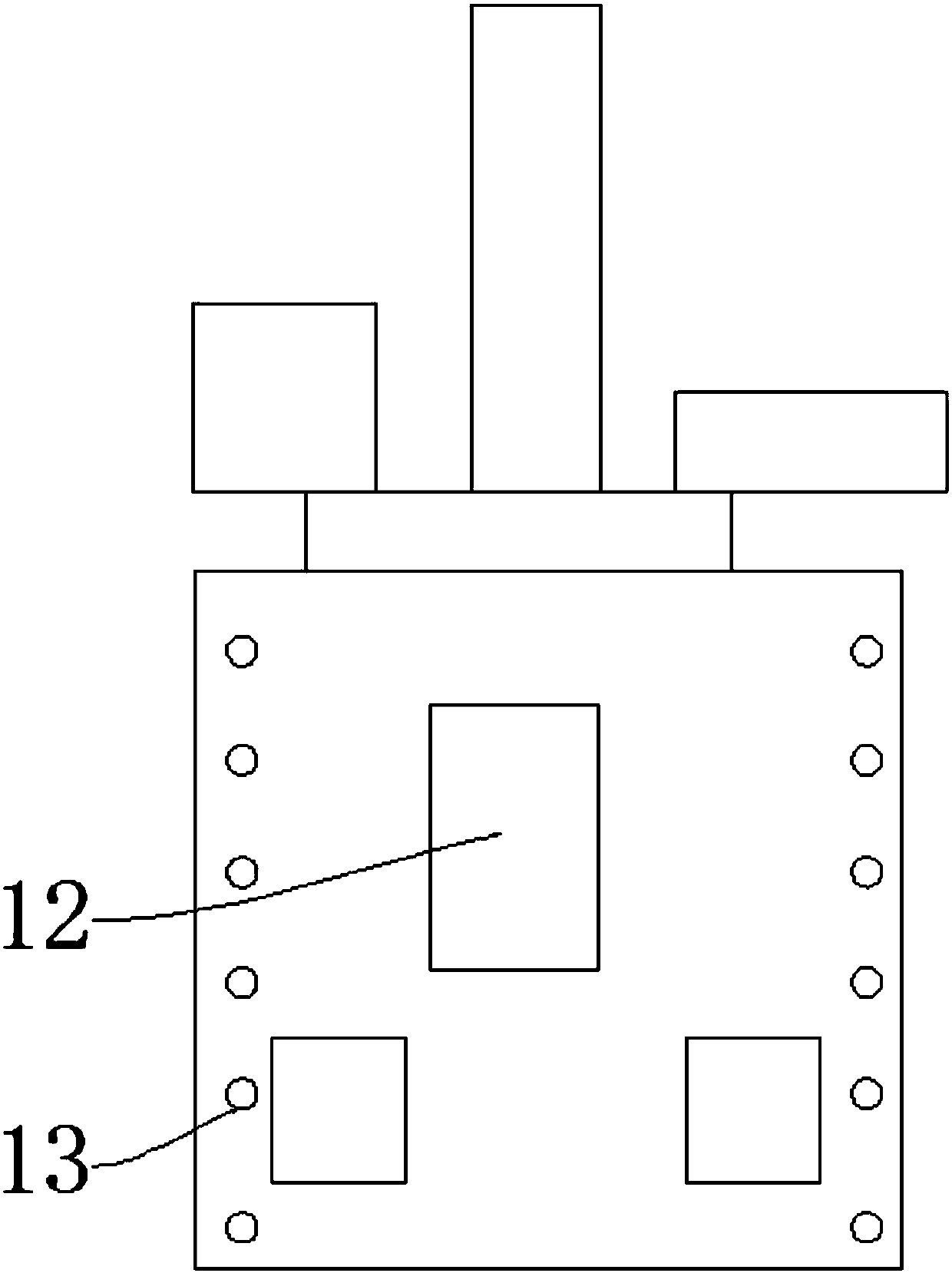

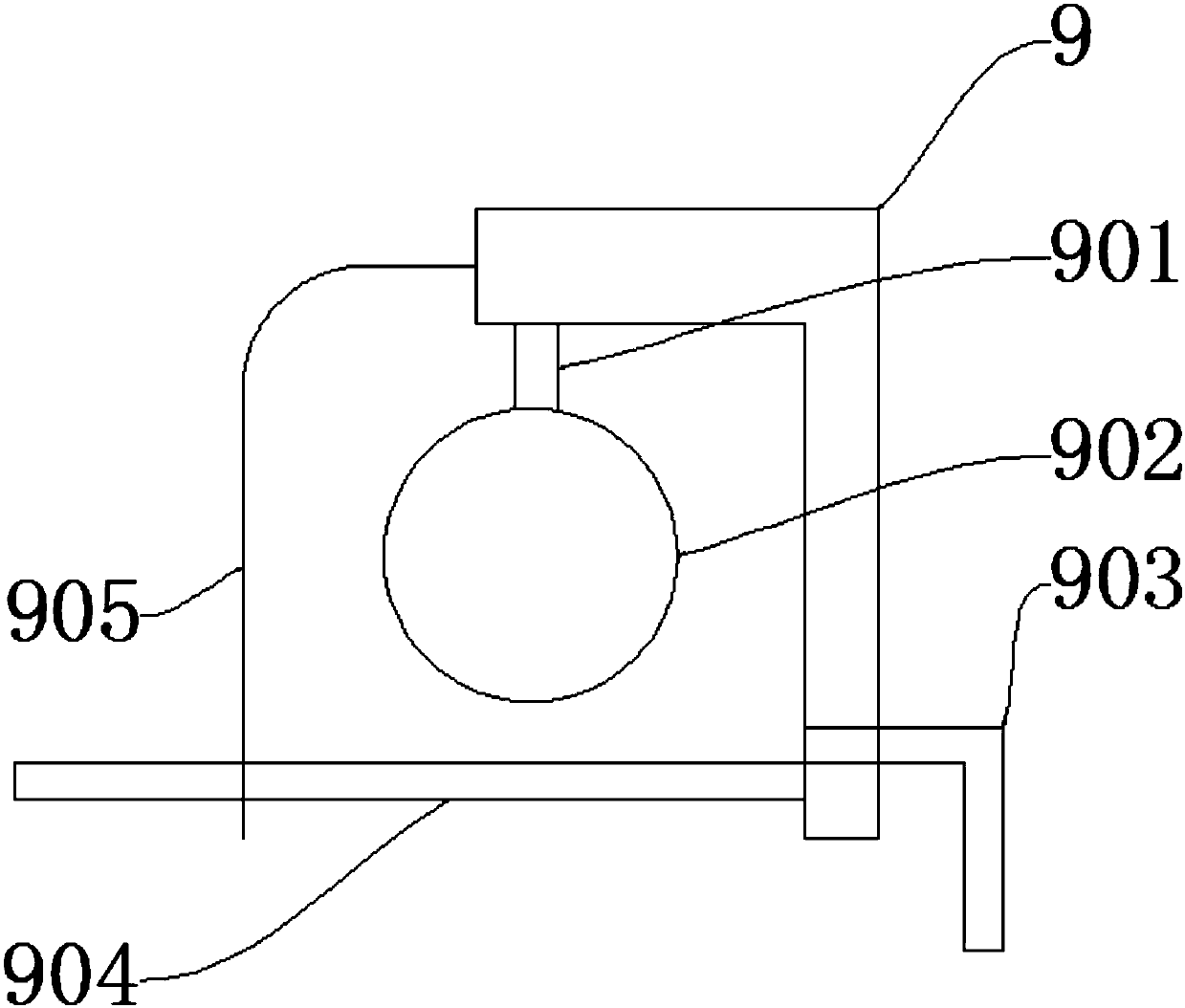

[0027] Such as Figure 1-Figure 5 As shown, a mechanical processing device and a mechanical processing method equipped with a waste recovery device include the main support leg 1 of the device, the motor support table 2, the material transportation motor 3, the transmission belt 4, the Infrared locator 6, described locator moving groove 7, described locator limit plate 8, described motor supporting platform 2 is arranged above the main support leg 1 of the device, described motor supporting platform 2 is provided with described A material transport motor 3, the transmission belt 4 is arranged above the material transport motor 3, the material transport platform 5 is installed above the transmission belt 4, and the infrared positioner 6 is installed above the material transport platform 5 , the positioner moving slot 7 is installed above the infrared positioner 6, the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com