Solder sucker with protection mechanism

A technology of protection mechanism and tin suction device, which is applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve the problems of fragile spring arms, difficult to disassemble, and easy to damage printed circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

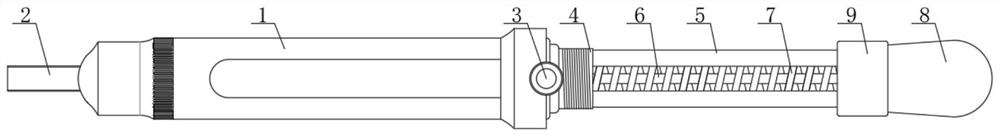

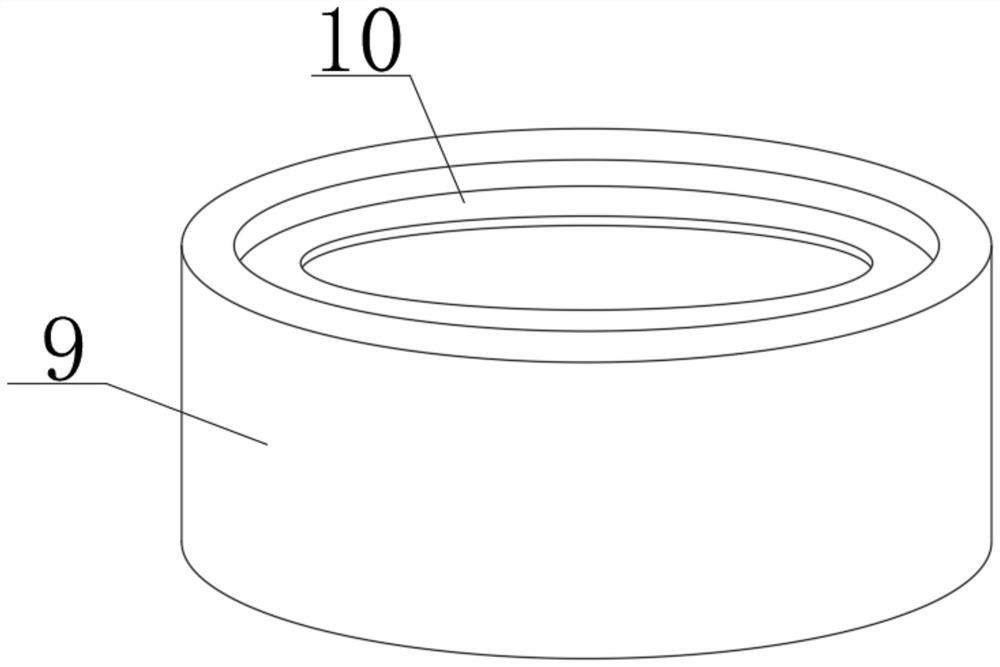

[0019] see figure 1 , figure 2 and image 3 , the present invention provides a technical solution:

[0020] A tin absorber with a protective mechanism, comprising a tin absorber body 1 and a tin absorber nozzle 2, one side of the tin absorber body 1 is fixedly connected with the tin absorber nozzle 2, and the front side of the tin absorber body 1 is fixedly connected with a button 3. There is a spring arm 5 slidingly connected inside the body 1 of the tin absorber. There is a support rod 6 inside the spring arm 5. A telescopic spring 7 is provided on the outside of the support rod 6. The right side of the spring arm 5 is fixedly connected with an upper force 8 to absorb tin. The other side of the device body 1 is fixedly connected with a threaded sleeve 4, and the outer side of the upper head 8 is rotatably connected with a rotating ring 10, and the outer side of the rotating ring 10 is fixedly connected with a rotating sleeve 9, and the left side of the tin absorber body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com