Preparation method of olefin rubber/filler blend vulcanized rubber

A technology of olefinic and vulcanized rubber, which is applied in the field of preparation of olefinic rubber and olefinic rubber/filler blended vulcanized rubber, which can solve the problems of short storage time of rubber latex, short storage time of solid rubber, easy deterioration and precipitation, etc. , to achieve the effect of excellent comprehensive performance of the product, improvement of physical and mechanical properties, and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

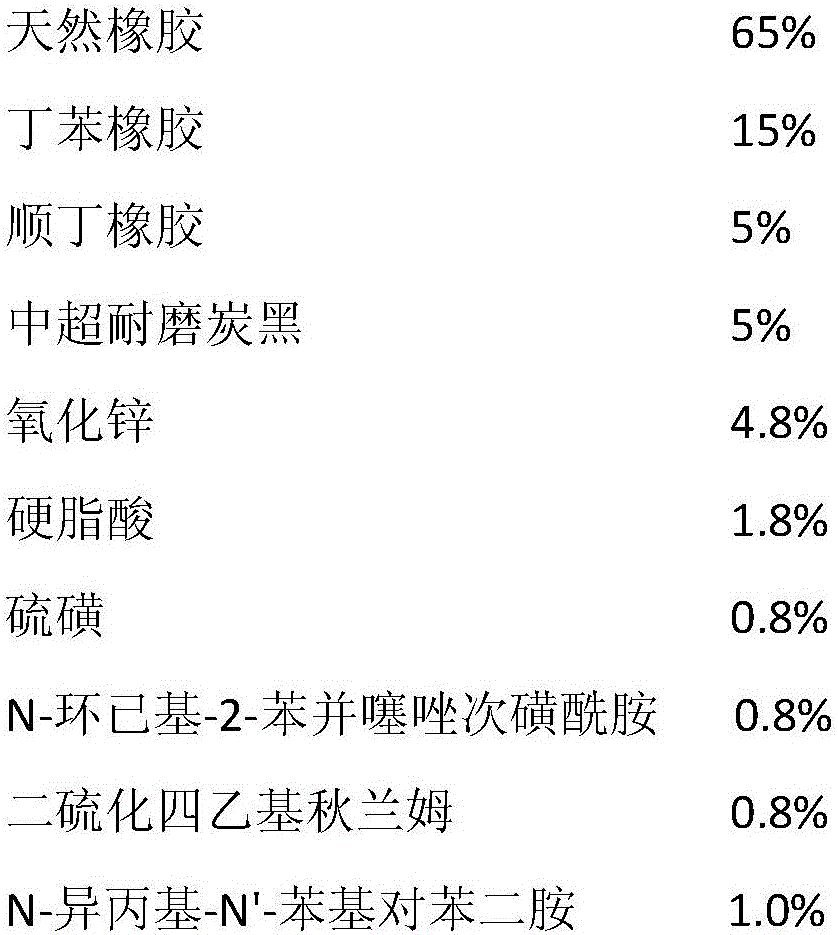

[0037] In terms of mass percentage, the consumption of each raw material is as follows:

[0038]

[0039] First add Zhongchao wear-resistant carbon black (N220) into deionized water (the mass ratio of N220 carbon black to deionized water is 1:5), then add sodium lauryl sulfate, stir mechanically for 180min, and rotate at a speed of 400r min ‐1 , Ultrasonic dispersion for 30min, power 1600w, to obtain N220 carbon black pre-dispersion.

[0040] The natural rubber raw rubber was masticated with a rubber internal mixer at a temperature of 40 °C and a rotor speed of 40 r min ‐1 , masticating for 5 minutes, adding styrene-butadiene rubber and butadiene rubber, mixing for 2 minutes, setting the temperature of the rubber internal mixer to 110 ° C, and the rotor speed to 40 r min ‐1 , add N220 carbon black pre-dispersion from the feeding port of the internal mixer, and the adding time is 5 minutes. During this process, a large amount of water vapor appears above the internal mixer....

Embodiment 2

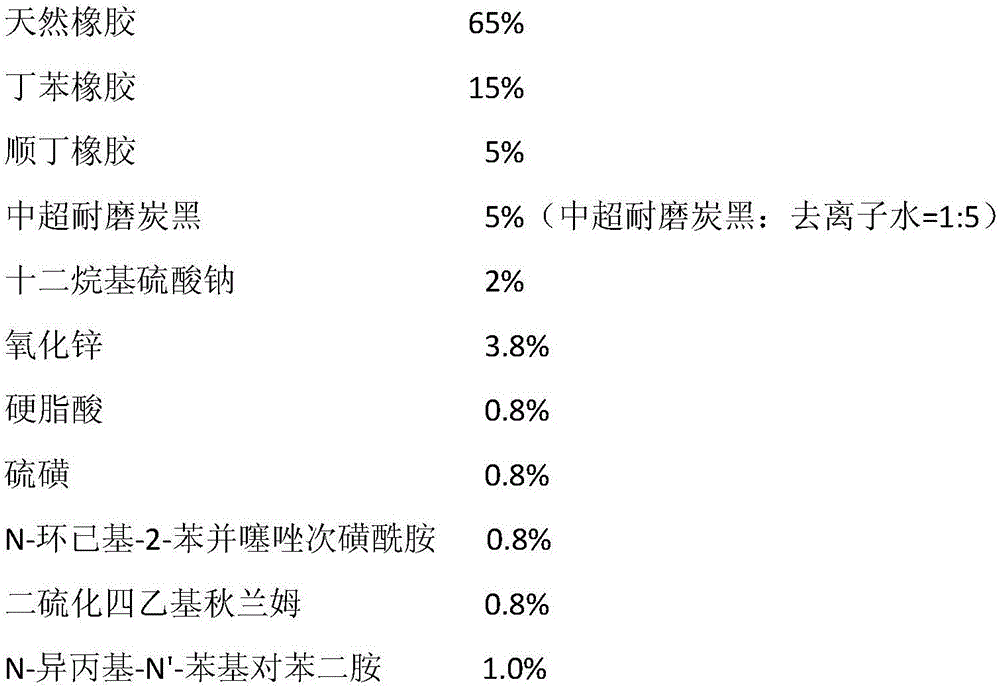

[0042] In terms of mass percentage, the consumption of each raw material is as follows:

[0043]

[0044] First add Zhongchao wear-resistant carbon black (N220) into deionized water (the mass ratio of N220 carbon black to deionized water is 1:30), then add sodium lauryl sulfate, stir mechanically for 30min, and rotate at a speed of 3000r min ‐1 , Ultrasonic dispersion for 180min, power 120w, to obtain N220 carbon black pre-dispersion.

[0045] The natural rubber raw rubber was masticated with a rubber internal mixer at a temperature of 40 °C and a rotor speed of 40 r min ‐1 , masticating for 5 minutes, adding styrene-butadiene rubber and butadiene rubber, mixing for 2 minutes, setting the temperature of the rubber internal mixer to 110 ° C, and the rotor speed to 40 r min ‐1 , add N220 carbon black pre-dispersion from the feeding port of the internal mixer, and the adding time is 10 minutes. During this process, a large amount of water vapor appears above the internal mixe...

Embodiment 3

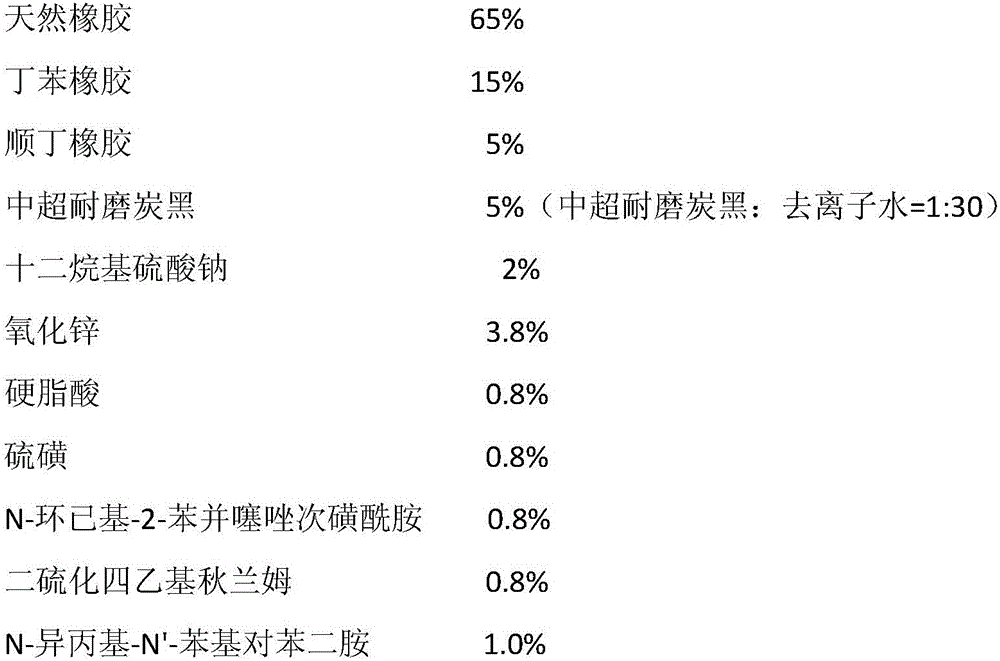

[0048] In terms of mass percentage, the consumption of each raw material is as follows:

[0049]

[0050]

[0051] First add Zhongchao wear-resistant carbon black (N220) into deionized water (the mass ratio of N220 carbon black to deionized water is 1:30), then add surfactant octylphenol polyoxyethylene ether, stir mechanically for 30min, and rotate at 3000r min ‐1 , Ultrasonic dispersion for 180min, power 120w, to obtain N220 carbon black pre-dispersion.

[0052] The natural rubber raw rubber was masticated with a rubber internal mixer at a temperature of 40 °C and a rotor speed of 40 r min ‐1 , masticating for 5 minutes, adding styrene-butadiene rubber and butadiene rubber, mixing for 2 minutes, setting the temperature of the rubber internal mixer to 110 ° C, and the rotor speed to 40 r min ‐1 , add N220 carbon black pre-dispersion from the feeding port, and the adding time is 15 minutes. During this process, a large amount of water vapor appears above the internal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com