Heavy belt-type movement machine

A technology of traveling machine and heavy-duty belt, which is applied in the direction of transportation, packaging, roller table, etc. It can solve the problems of high maintenance cost for users, limit the use range of chain traveling machine, and cannot further increase the speed, etc., and achieve easy maintenance and maintenance , Accelerate the production tempo and take up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

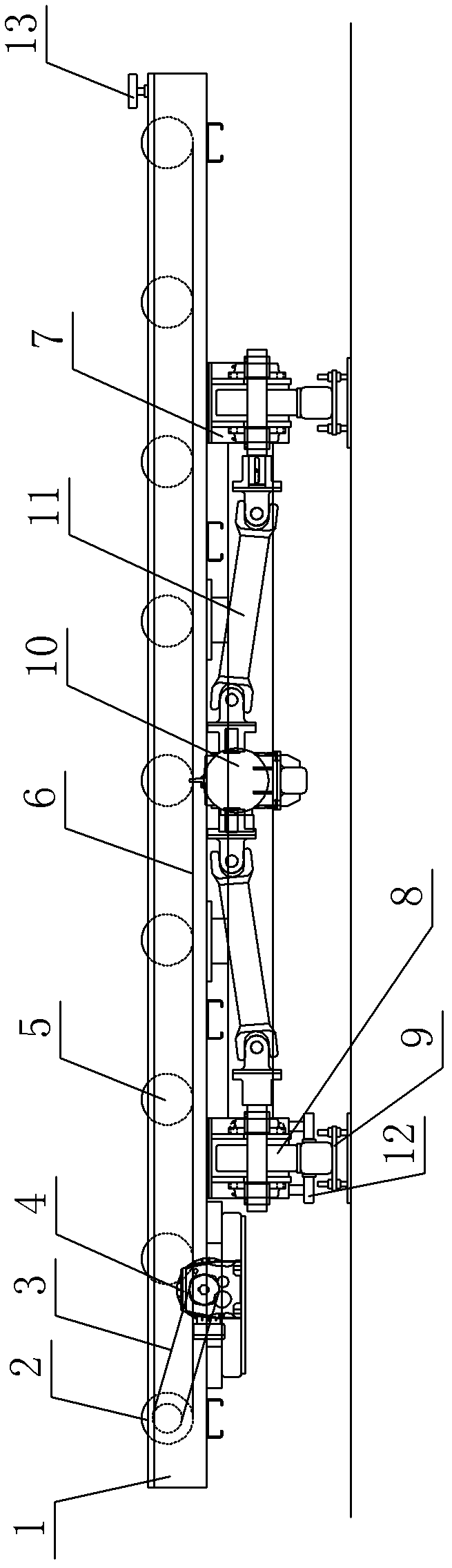

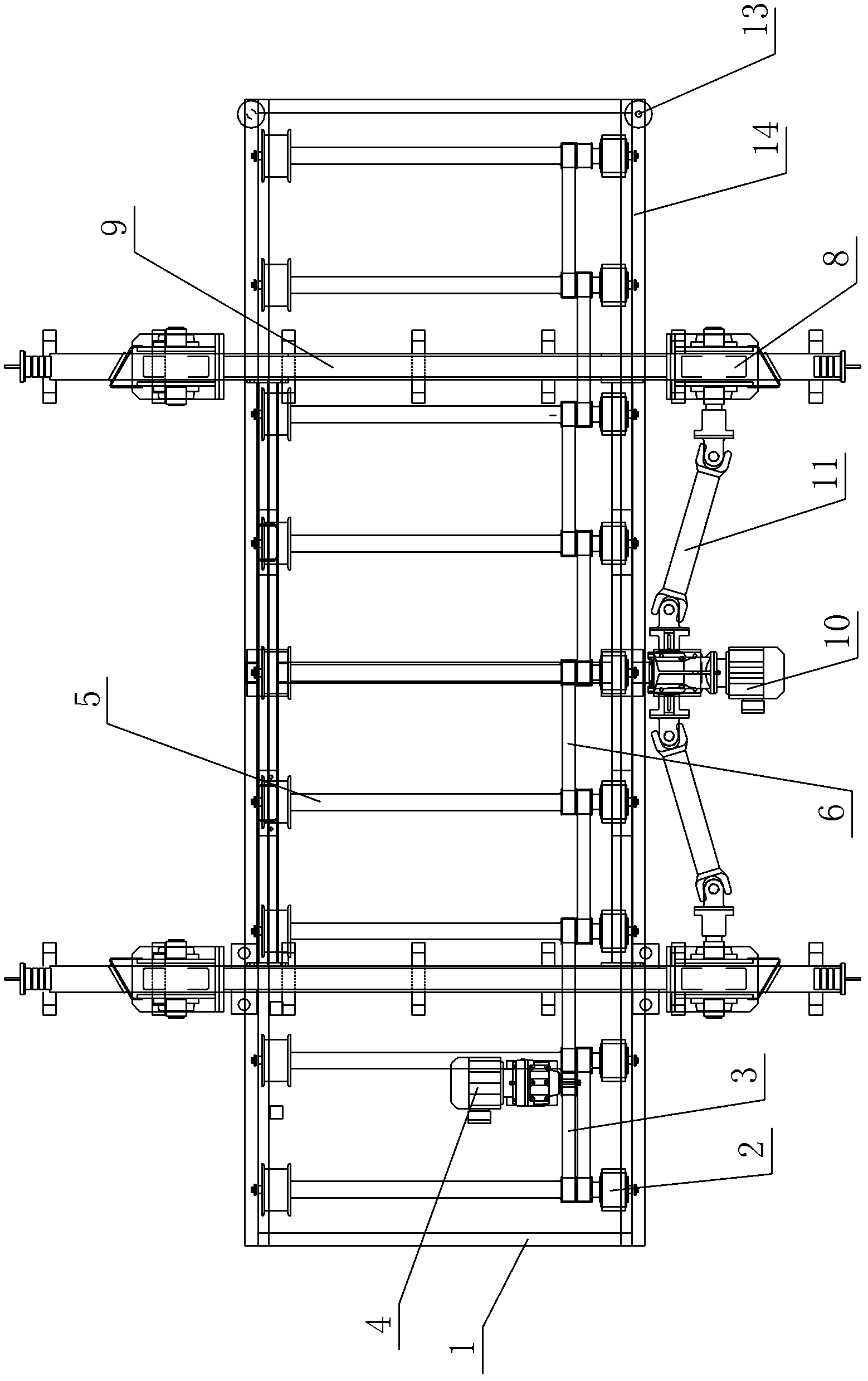

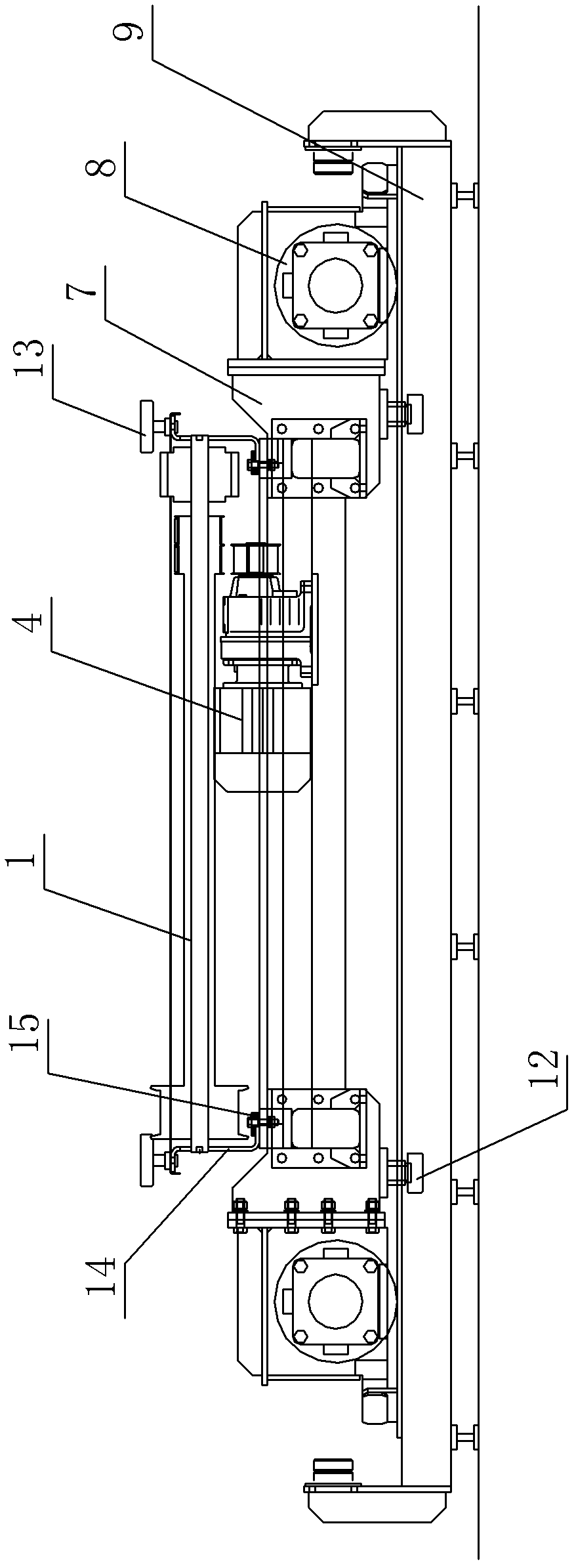

[0016] see Figure 1 to Figure 3 As shown, in this embodiment, a heavy-duty belt-type traveling machine includes a frame 7 and a bearing roller bed assembled on the frame 7 through a pressing plate 15. The bearing roller bed includes a bracket 1 and a A drive roller 2 and a plurality of driven rollers 5, the drive roller 2 is connected to the roller drive motor 4 through the drive belt 3, and the drive belt 6 is connected to the drive roller 2 and each driven roller 5, the machine Two running wheels 8 are installed on both sides of the frame 7, two rails 9 installed on the ground or steel structure platform are arranged in parallel with the running wheels 8, and on the frame 7 between the walking wheels 8 on the two sides A traveling wheel driving motor 10 is installed, and the power output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com