A new online monitoring system for oilfield produced water

A technology for monitoring systems and produced water, which is applied in the direction of testing water, instruments, and analytical materials, etc., and can solve problems such as lightning strikes, exceeding standards, and short circuits of online monitoring equipment, and achieve the effect of standardized installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

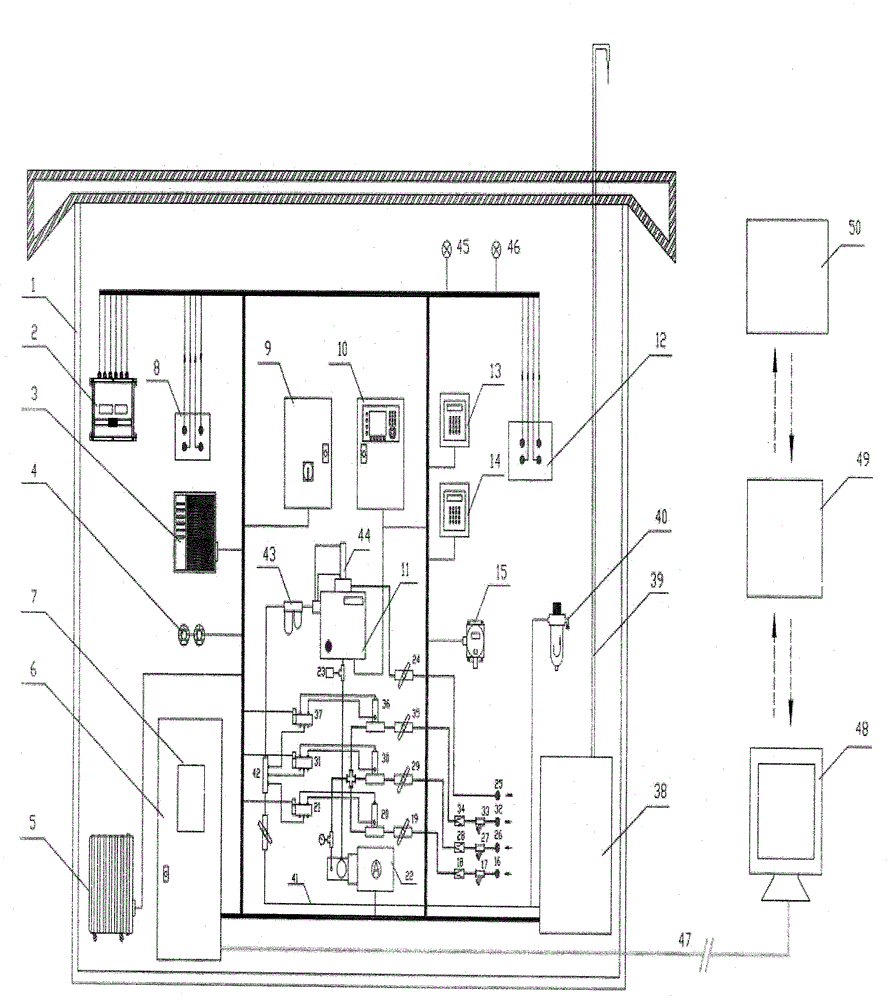

[0028] refer to figure 1 , a new online monitoring system for oilfield produced water, including non-explosion-proof online monitoring equipment, which is highly integrated and installed in an integrated positive pressure explosion-proof analysis cabin.

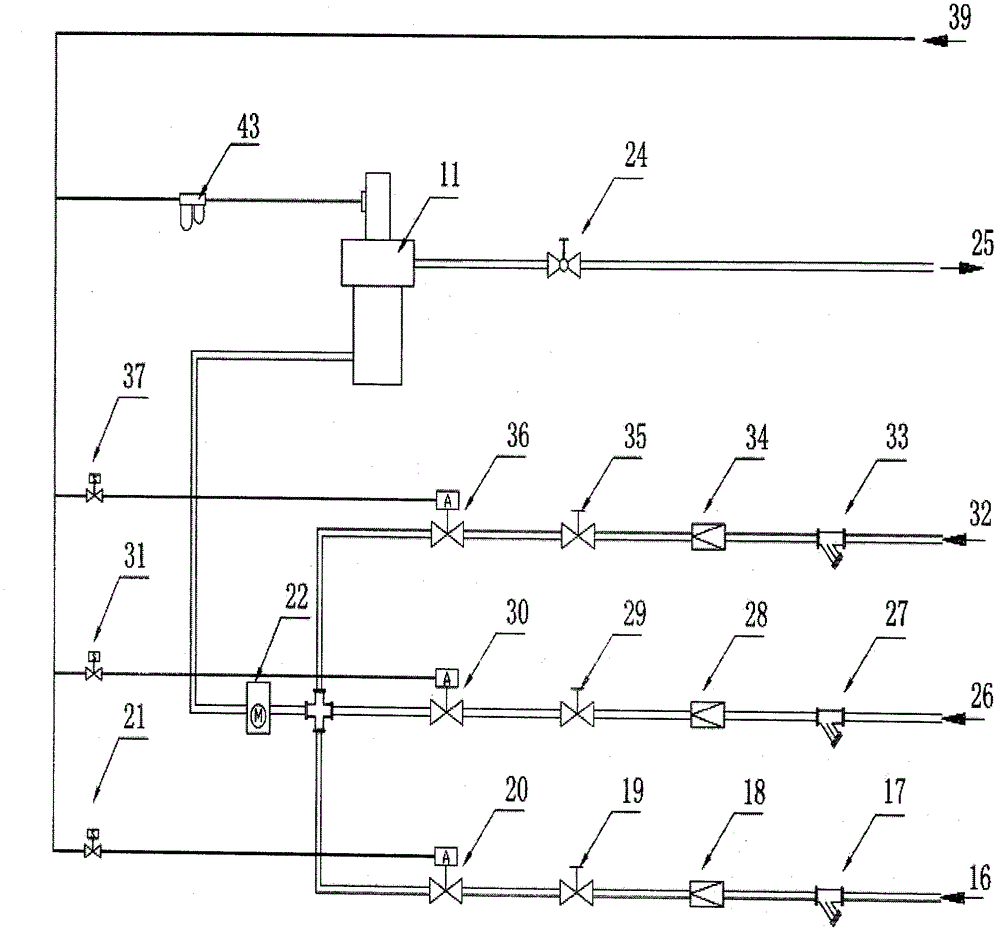

[0029] The sampling and pretreatment unit of the online monitoring system arranges three sampling points at the outlet of the settling tank, the outlet of the purification tank, and the outlet of the clean water tank, and connects with the inlet of the monitoring and analysis unit, and connects the outlet of the monitoring and analysis unit with the discharge pipeline.

[0030] Non-explosion-proof online monitoring equipment includes: PLC control cabinet 6, true color touch screen 7, oil meter controller 9, oil meter host 10, oil meter 11, purified water flow meter 13, sewage flow meter 14, sampling Pump 22, air co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com