Conveyor system for electrothermal film element production line

A technology of conveying system and production line, applied in the field of conveying system, can solve problems such as polluting production lines, and achieve the effect of clean and tidy working environment, avoiding breakage and ensuring working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

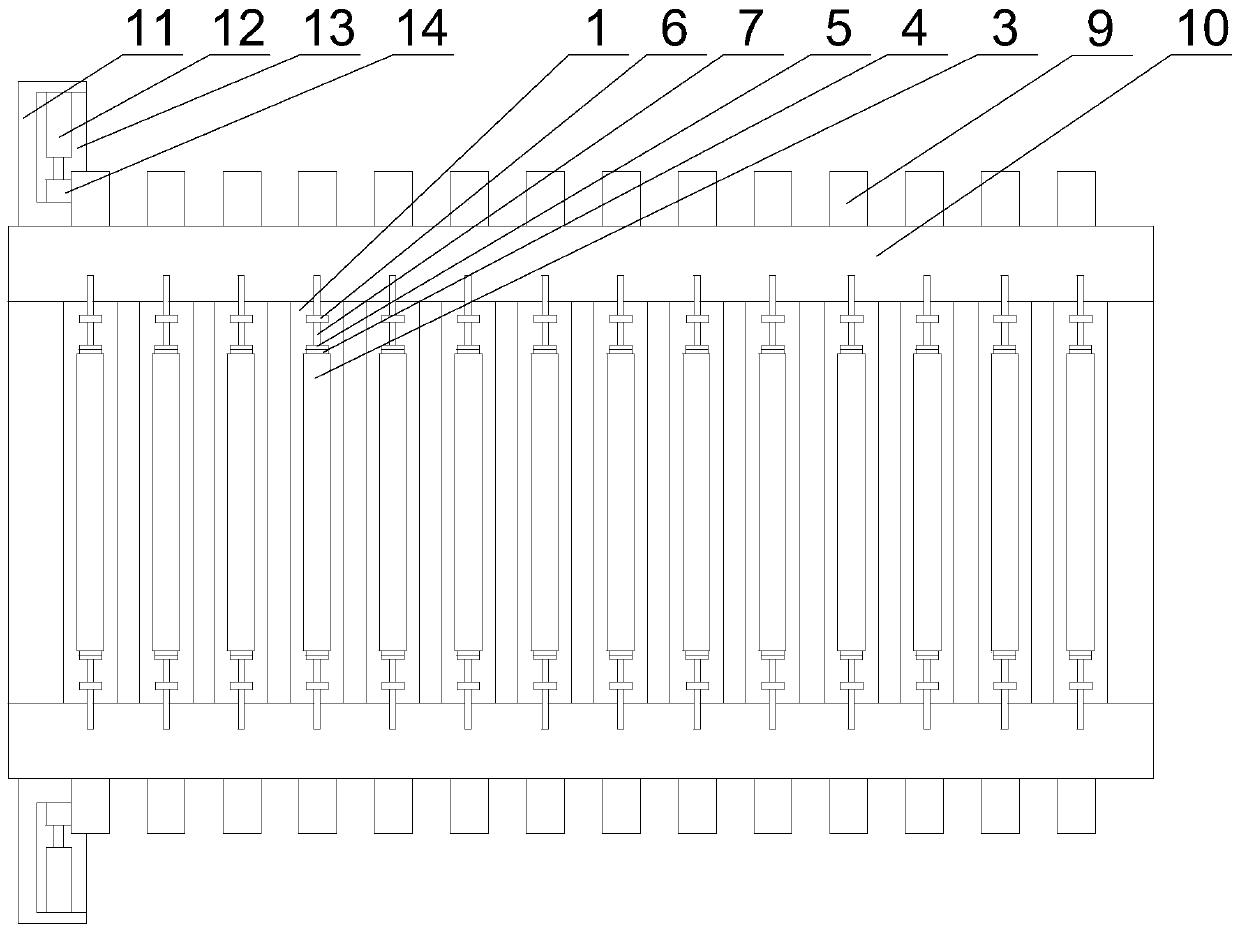

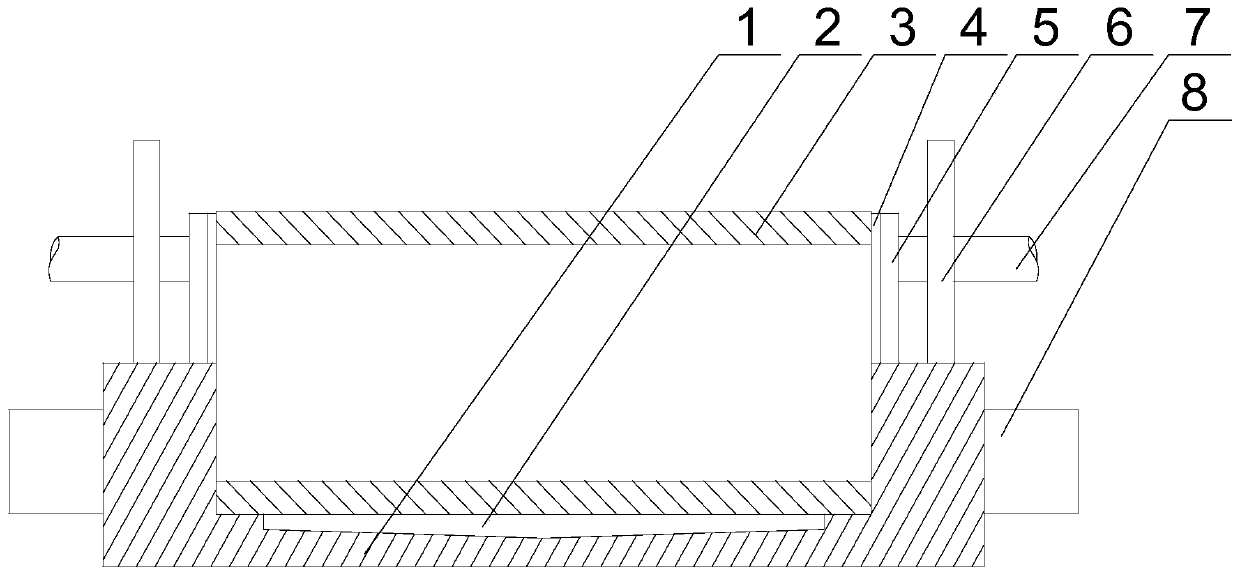

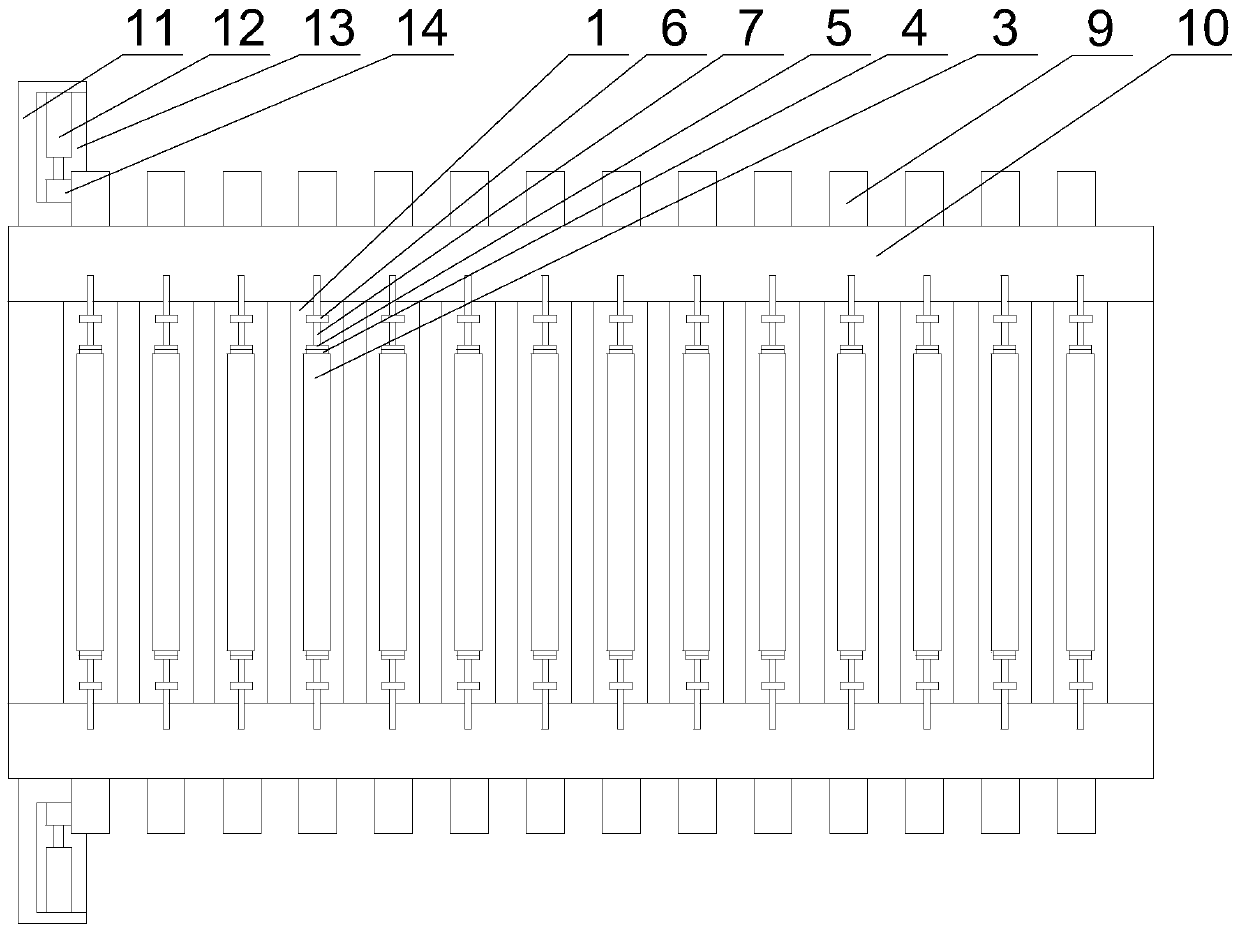

[0023] Such as Figure 1~2 As shown, this embodiment includes two transmission chains 10, and a plurality of rollers 1 perpendicular to the transmission chains are rotated between the two transmission chains, and the rotating shafts 8 at both ends of the rollers 1 move through the transmission The chain extends outwards, and a transmission gear 9 is installed on the rotating shaft 8, a rectangular groove for placing the glass tube 3 is opened on the upper surface of the roller 1, and a support 11 is provided on the side walls of the two transmission chains 10 , the vertically placed cylinder is fixed on the support 11, the output end of the cylinder is fixed with a base plate 13, the motor 12 is fixed on the base plate 13, and the output end of the motor 12 is equipped with a main gear that cooperates with the transmission gear 9 14, and in the initial state, the main gear 14 is located directly below the transmission gear 9, and the main gear 14 is not in contact with the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com