Timed automatic cleaning and water recovery circulatory system

A circulatory system and automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of time-consuming and laborious cleaning, waste of water resources, hardening, etc., and achieve a clean and tidy working environment. , Save manpower and material resources, and ensure the effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

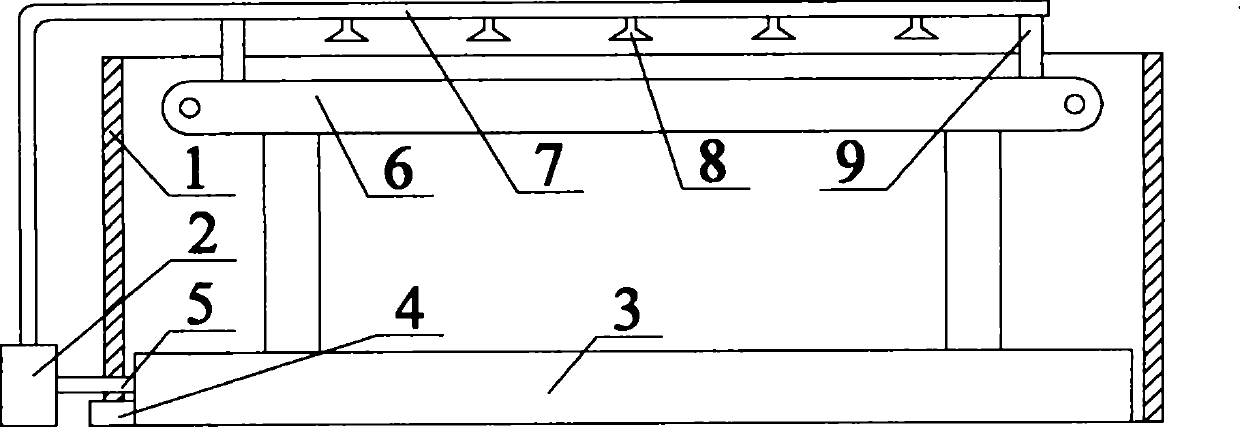

[0012] Embodiment 1: According to the initial setting time of the slurry, the control unit is used to set the interval time of the high-pressure pump 2 to be 25 minutes, and the spray washing time is 2 minutes. When the set interval time is reached, the control unit sends a signal to make the molding machine Stop working, and at the same time the control unit outputs the signal to open the solenoid valve on the high-pressure pump 2 and the high-pressure nozzle 8, and the water in the settling tank 3 enters the spray pipe 7 through the water outlet 5 under the action of the high-pressure pump 2, and is discharged by the high-pressure nozzle 8. Spray out to clean off the powder ash and slurry on the molding machine. After the spraying time is reached, the control unit sends a control signal to close the high-pressure pump 2 and the solenoid valve, and at the same time, the molding machine is turned on to continue working. The cleaned water flows into the sedimentation tank 3 Prec...

Embodiment 2

[0013] Embodiment 2: According to the initial setting time of the slurry, the control unit is used to set the interval time of the high-pressure pump 2 to be 35 minutes, and the spray washing time is 3 minutes. When the set interval time is reached, the control unit sends a signal to make the molding machine Stop working, and at the same time the control unit output signal to turn on the high-pressure pump 2, and make the solenoid valves on the high-pressure nozzle 8 cycle open in sequence, and the water in the settling tank 3 enters the spray pipe through the water outlet 5 under the action of the high-pressure pump 2 7. It is sprayed by the high-pressure nozzle 8 to clean the powder ash and slurry on the molding machine. Each high-pressure nozzle 8 is sprayed for 3 to 5 seconds. After the spraying time is reached, the control unit sends a control signal to connect the high-pressure pump 2 and the solenoid valve. Close, make molding machine open and continue to work at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com