Welding seam tracking method in membrane wall welding process

A technology of welding process and water-cooled membrane wall, which is applied in the field of tracking and detection, can solve the problems of difficult welding and the failure of monitoring and tracking technology to achieve the effects of ensuring tracking of weld seams, enhancing core competitiveness and improving welding productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

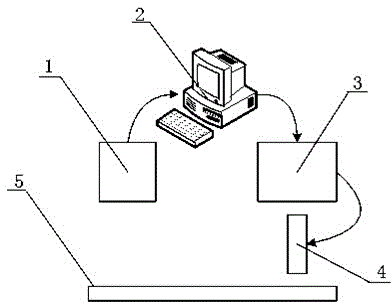

[0015] Such as figure 1 The block diagram of the seam tracking system in the welding process of the membrane water wall is shown, mainly including the laser vision sensor 1, the vision recognition server 2, the adaptive welding torch adjustment device 3 and the welding torch 4, and the deployment of the laser vision sensor 1 in front of the welding torch 4, Including adding an adaptive welding torch adjustment device 3 on each welding torch 4, collecting video information of the weld 5 between flat steel and adjacent steel pipes through the laser vision sensing device 1 in front of each welding torch, and the collected video information will be sent to the visual recognition The server 2, the server 2 quickly recognizes the change of the weld 5 through the digital image processing software; when the server 2 detects the change of the weld 5, the server 2 specifies the position and angle of the weld 5 at the moment of the adaptive welding torch adjustment device 3 Information, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com