Spray booth for automatically recycling spray mist through electrostatic adsorption

A technology of electrostatic adsorption and electrostatic adsorption net, which is applied in the field of spraying booths, can solve the problems of strong volatility and toxicity of paint, pollution of the working environment, waste of water resources, etc., to reduce the damage to workers' bodies and the environment, ensure personal safety, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

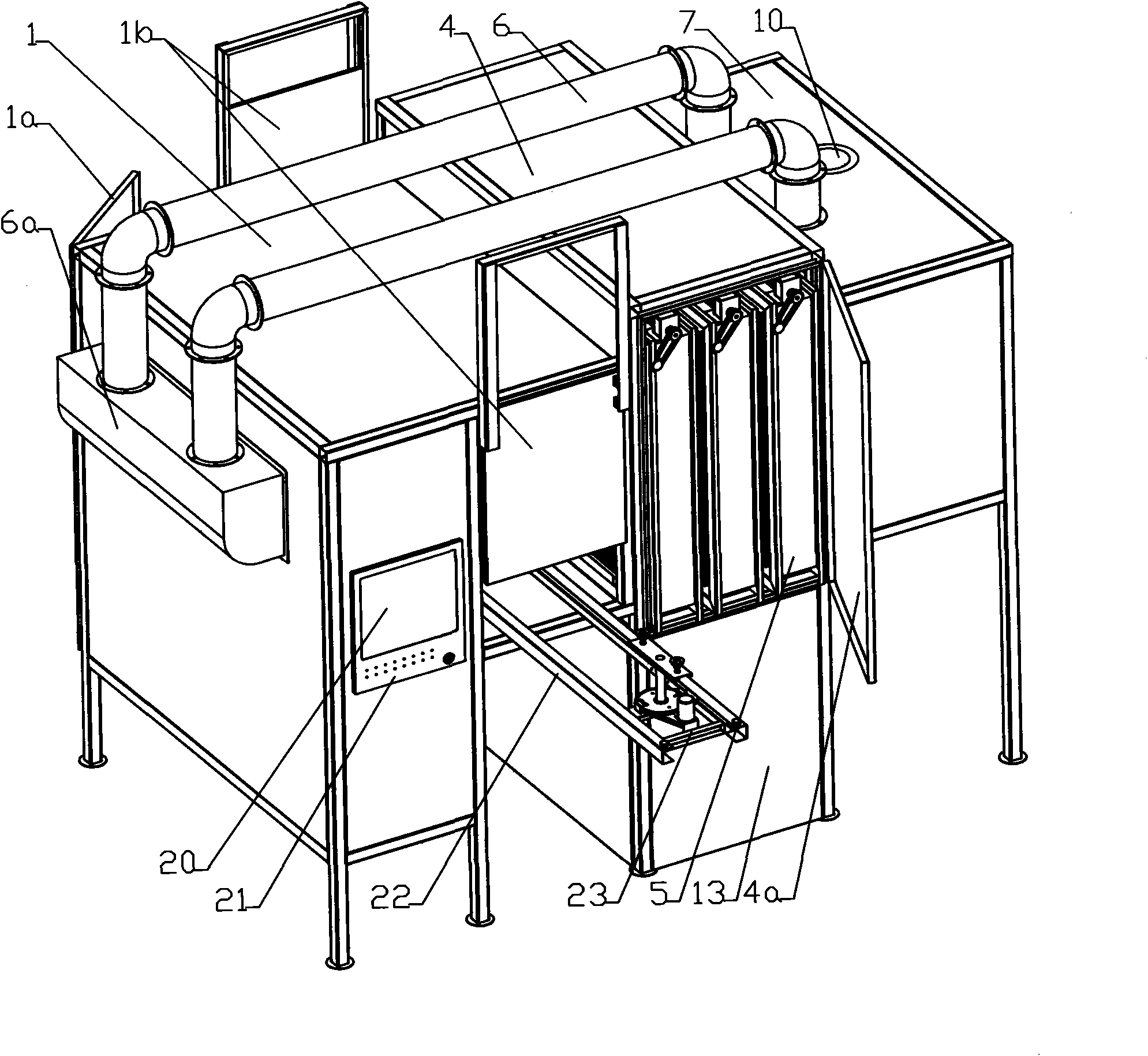

[0038] The specific implementation of the spray booth for automatic electrostatic adsorption and recovery of paint mist of the present invention will be described in detail below in conjunction with the accompanying drawings.

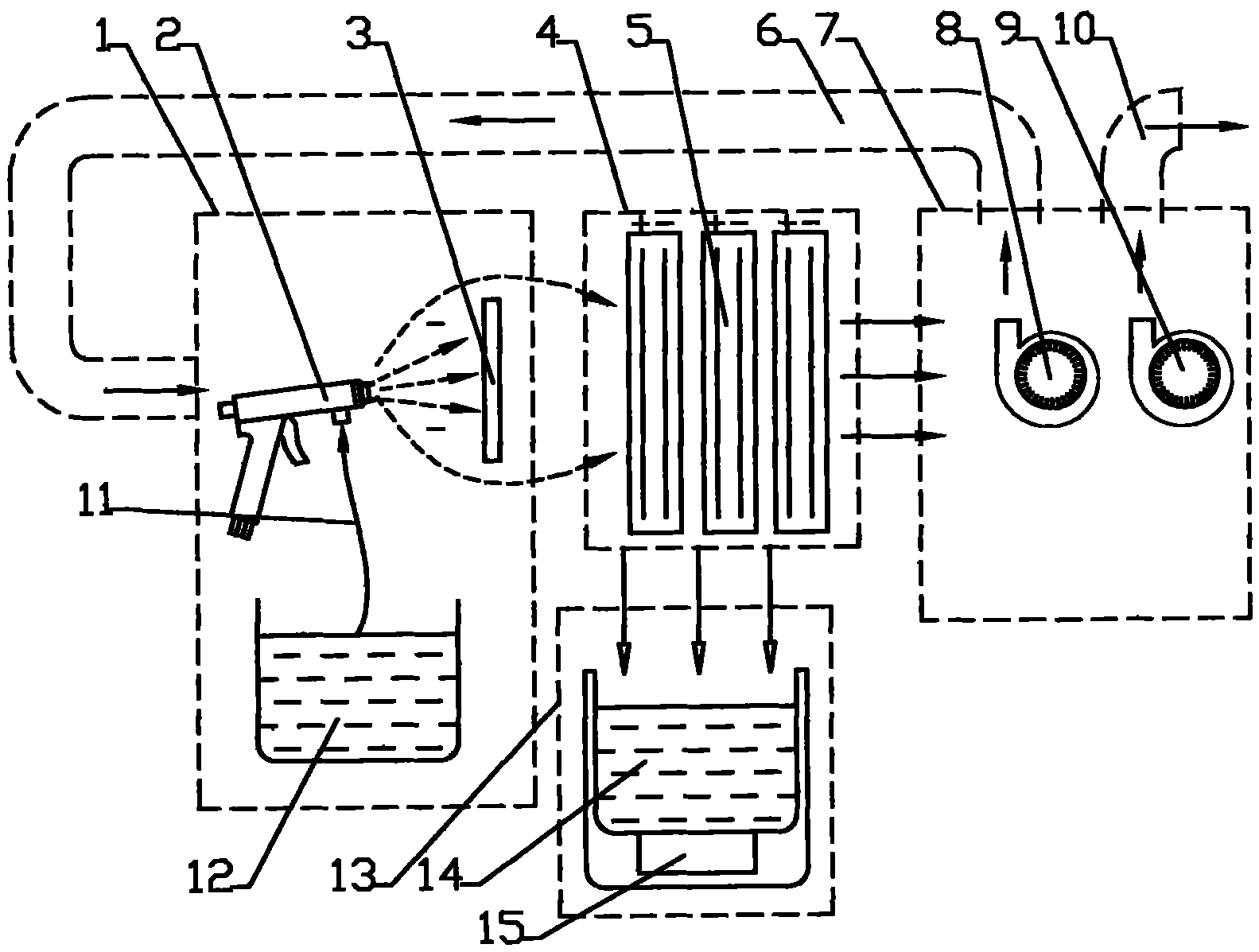

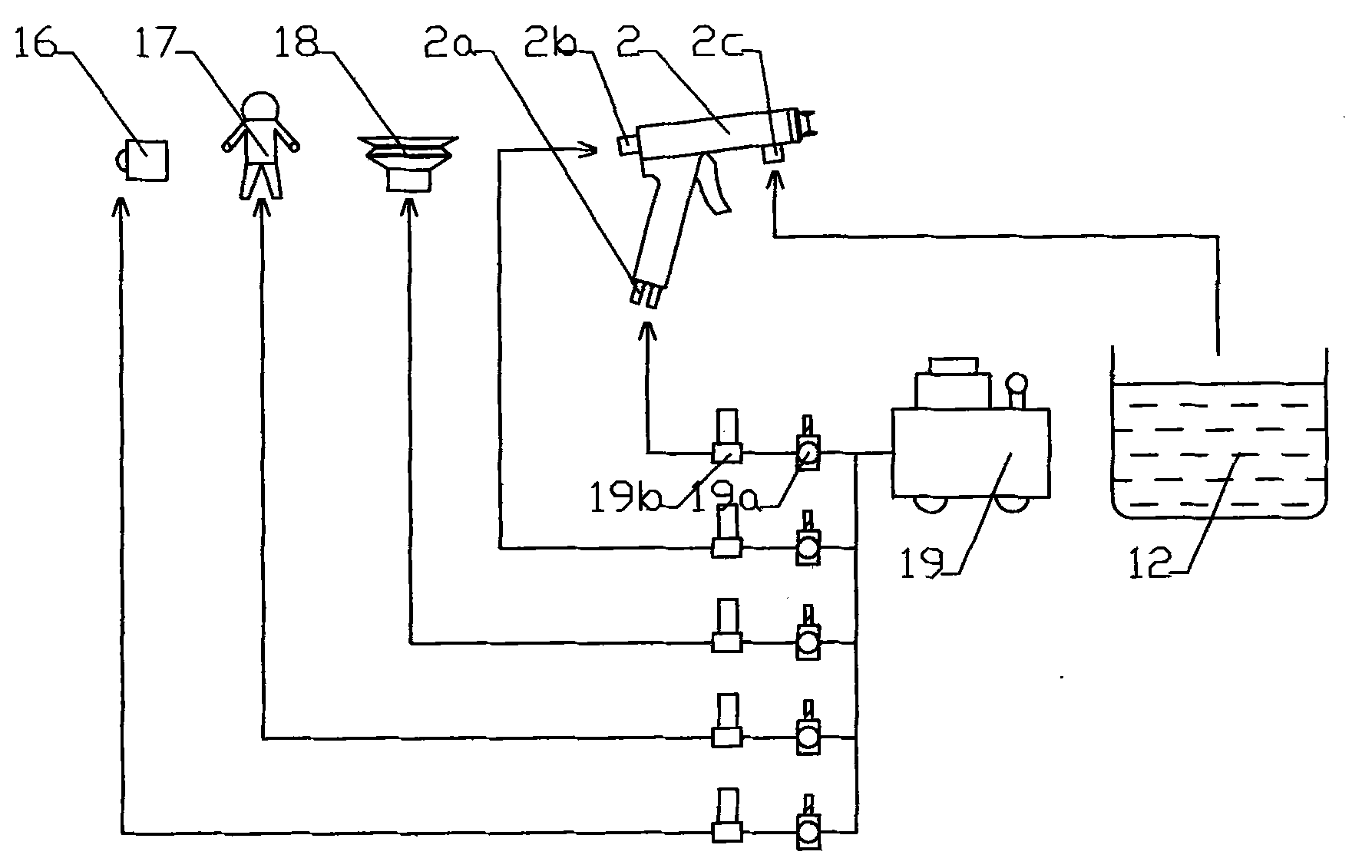

[0039] Such as figure 1 Shown in is the working principle diagram of the present invention, namely paint bucket 12 connects paint pipe 2c to provide paint for electrostatic spray gun 2 through flexible pipe 11, and the paint mist sprayed out by electrostatic spray gun 2 has negative charge, and its part covers On the surface of the workpiece 3, a part of it crosses the workpiece 3 and enters the electrostatic field of the electrostatic adsorption net 5, thereby being adsorbed to its positive electrode, and the adsorbed paint then falls into the recovery bucket 14, which has a refrigerator 15 to ensure recovery The paint is at low temperature to avoid a large amount of volatilization, so as to achieve the purpose of effective recycling.

[0040] Moreove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com