Interface bonding-enhanced aramid fiber composite material preparation method

An aramid fiber composite material and interfacial bonding technology, applied in the field of composite material preparation, can solve problems such as poor interfacial bonding performance, and achieve the advantages of reducing crosslinking density, improving interlayer shear performance, and improving interfacial bonding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

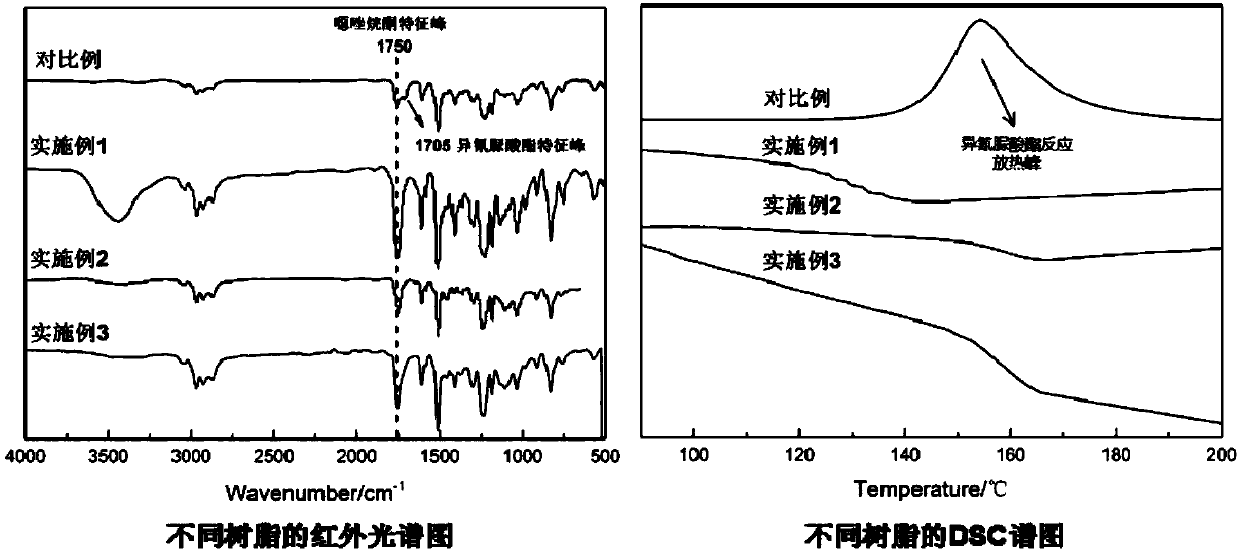

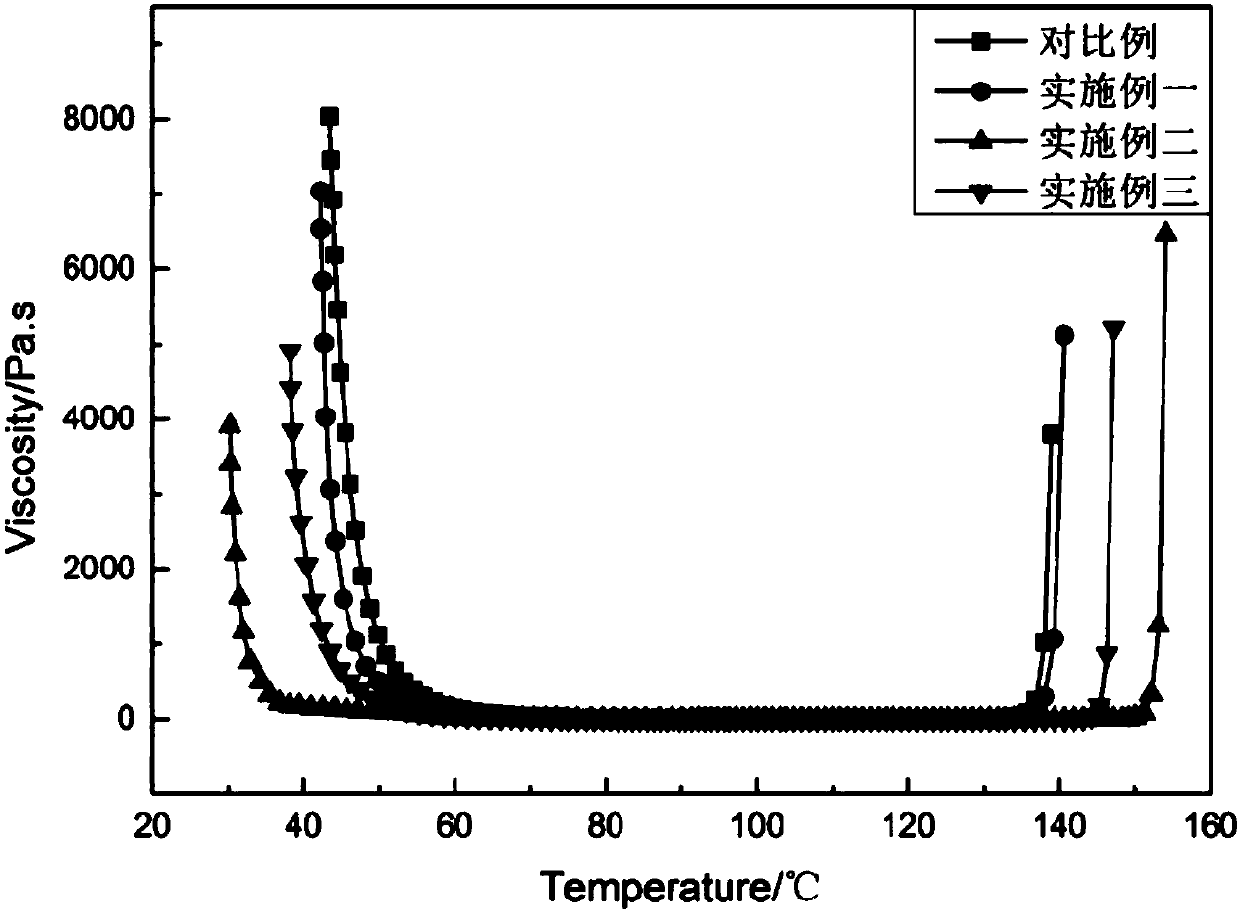

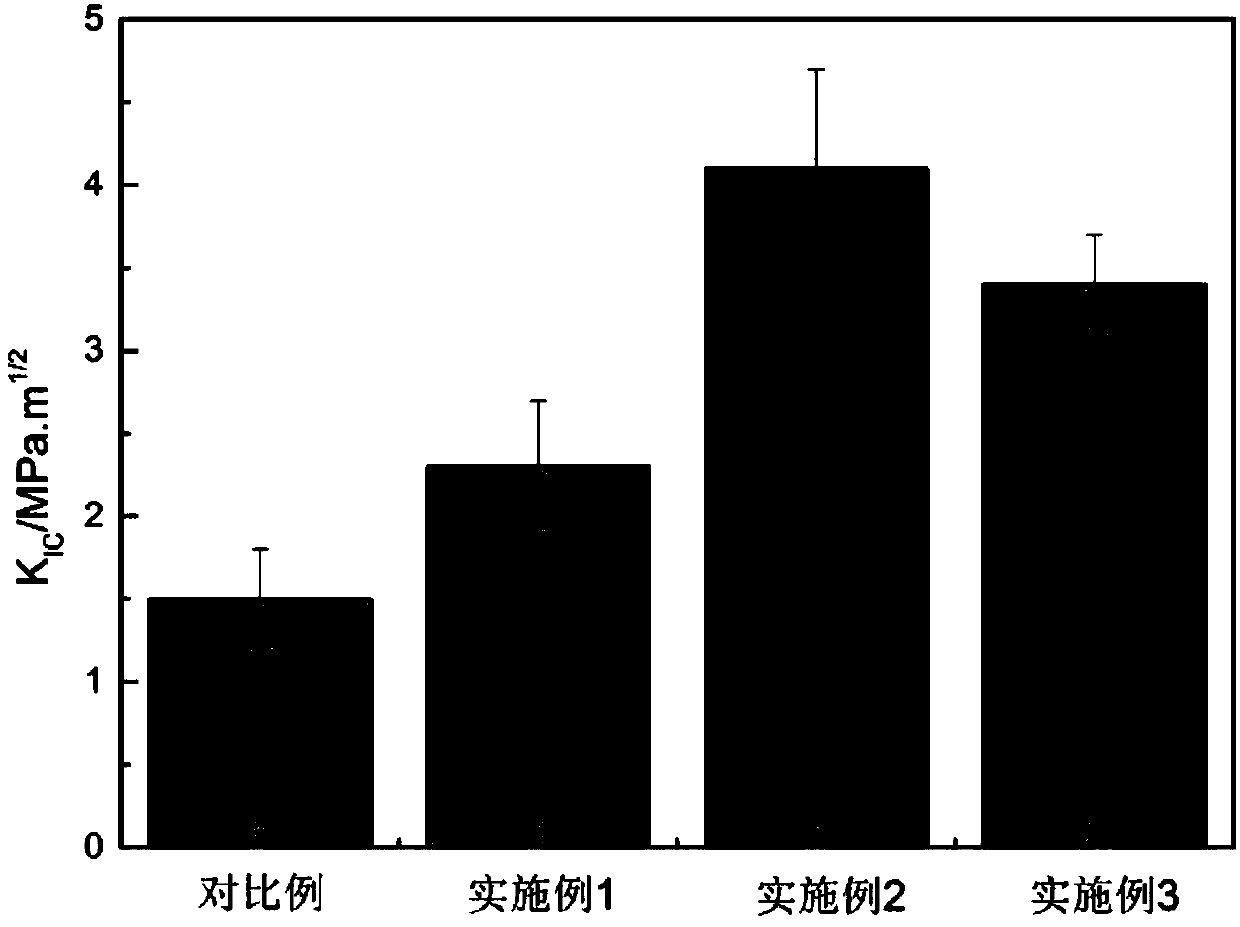

[0023] The diphenylmethane diisocyanate and bisphenol A epoxy resin are according to the NCO:epoxy molar ratio of 1:2, add the catalyst 2-methylimidazole, and react at 200 ° C for 2 hours to obtain a modified epoxy resin, relative to 100 1 part modified epoxy resin, the massfraction of catalyst is 0.02 part; In above-mentioned modified epoxy resin, add trifunctionality glycidyl amine epoxy resin and dicyandiamide and 3-phenyl-1,1-dimethyl The urea curing system is kneaded to obtain a prepreg epoxy resin system, wherein the total amount of trifunctional glycidylamine epoxy resin and modified epoxy resin is 100 parts, and the trifunctional glycidylamine epoxy resin is 30 parts. Dicyandiamide is 8 parts, 3-phenyl-1,1-dimethylurea is 1 part; the obtained resin system is coated with a film machine, and compounded with aramid fiber prepreg through a compound machine to obtain aramid fiber For fiber prepreg, place the cut prepreg in a mold, and obtain a composite sheet at 130°C for 2...

Embodiment 2

[0026] Toluene diisocyanate and bisphenol F epoxy resin are NCO:epoxy molar ratio of 1:5, add catalyst N,N-dimethylbenylamine, and react at 150°C for 6 hours to obtain modified epoxy resin. 100 parts of modified epoxy resin, the mass fraction of the catalyst is 0.5 part; add bisphenol A glycidyl ether to the above modified epoxy resin and knead with dicyandiamide and diaminodiphenylmethane curing system to obtain a prepreg ring Oxygen resin system, wherein the total amount of bisphenol A glycidyl ether and modified epoxy resin is 100 parts, bisphenol A glycidyl ether is 60 parts, dicyandiamide is 10 parts, and diaminodiphenylmethane is 10 parts Parts; the obtained resin system is coated with a film machine, and compounded with aramid fiber prepreg through a compound machine to obtain aramid fiber prepreg, and the cut prepreg is placed in a mold, and the composite Material sheet.

[0027] The monitoring of the reaction end point of modified epoxy in the present invention is as...

Embodiment 3

[0029] Hexamethylene diisocyanate and novolak type epoxy resin according to NCO:epoxy molar ratio of 1:2.5, add catalyst 2-ethyl-4-methylimidazole, react at 170°C for 3h, and obtain modified epoxy resin , relative to 100 parts of modified epoxy resin, the mass fraction of the catalyst is 0.3 parts; add liquid novolac epoxy resin, dicyandiamide and imidazole curing agent to the above modified epoxy resin and knead to obtain a prepreg epoxy resin system , where the total amount of liquid novolak epoxy resin and modified epoxy resin is 100 parts, liquid novolac epoxy resin is 50 parts, dicyandiamide is 10 parts, and imidazole is 2 parts; The machine-coated film is compounded with aramid fiber prepreg through a compound machine to obtain aramid fiber prepreg, and the cut prepreg is placed in a mold, and the composite material sheet is obtained at 130°C for 2h.

[0030] The monitoring of the reaction end point of modified epoxy in the present invention is as follows: adopt the char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com