Thick coating type aqueous epoxy zinc-rich anticorrosive coating material and preparation method thereof

A technology of water-based epoxy zinc-rich and anti-corrosion coatings, applied in the field of coatings, can solve problems such as sagging, thickening and anti-settling effect damage, and water-based epoxy zinc-rich coatings spraying construction sagging, etc., to increase viscosity and facilitate irrigation installation, good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

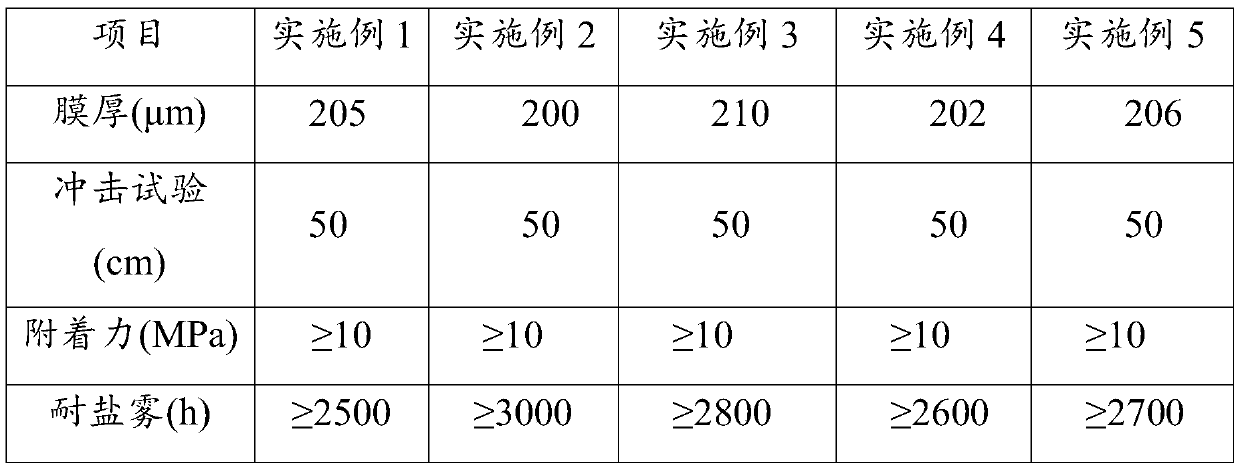

Examples

Embodiment 1

[0036] The thick-coated water-based epoxy zinc-rich anti-corrosion coating of this embodiment is prepared by mixing component A, component B and water at a mass ratio of 3:1:0.3, wherein the component A contains 10 parts of adducts of aliphatic amines and alicyclic amines, 0.5 parts of dispersant Additol VXW 6208, 0.05 parts of defoamer Additol VXW 6393, 2.1 parts of organic bentonite 881, 0.1 parts of thixotropic agent RM-12W, 0.05 parts of thixotropic Agent ATUR10, 0.2 parts of thixotropic agent DeuRheo 229, 0.8 parts of fumed silicon A200, 1.2 parts of fumed silicon R974, 5 parts of thixotropic synergist BYK-P 2720, 60 parts of spherical zinc powder (particle size 5 μm), 20 parts of propylene glycol methyl Ether; the second component includes 55 parts by mass parts of 6520 epoxy emulsion, 2 parts of W2N lithium magnesium silicate, 1 part of BYK420 modified polyurea, 2 parts of A200 gas silicon, 5 parts of thixotropic blocking agent BYK- P 2710 and 35 parts water.

[0037] ...

Embodiment 2

[0042] The thick-coated water-based epoxy zinc-rich anticorrosion coating of this embodiment is prepared by mixing component A, component B and water at a mass ratio of 4:1:0.5, wherein the component A contains 7.5 parts of aromatic amine and polyamide adduct, 1 part of dispersant Additol VXW 6208, 0.5 part of defoamer Additol VXW 6393, 2 parts of organic bentonite 881, 1 part of thixotropic agent ATUR10, 2 parts of thixotropic agent DeuRheo 229, 2 parts of thixotropic synergist BYK-P 2720, 69 parts of spherical zinc powder (particle size 5 μm), 15 parts of propylene glycol methyl ether; the B component contains 63 parts of 6520 epoxy emulsion, 2 parts of EXILVA fiber in parts by mass element, 2 parts of BYK420 modified polyurea, 4 parts of A200 fumed silicon, 9 parts of thixotropic blocking agent BYK-P 2710 and 20 parts of water.

[0043] The preparation method of the thick coating type waterborne epoxy zinc-rich anticorrosion coating of the present embodiment may further com...

Embodiment 3

[0048] The thick-coated water-based epoxy zinc-rich anticorrosion coating of this embodiment is prepared by mixing component A, component B and water at a mass ratio of 5:1:0.8, wherein the component A contains 7.5 parts of adducts of aliphatic and aromatic amines, 1.2 parts of dispersant Additol VXW 6208, 0.8 parts of defoamer Additol VXW 6393, 0.1 part of organic bentonite 881, 0.1 part of thixotropic agent RM-12W, 0.2 part of thixotropic agent DeuRheo 229, 0.1 part of fumed silicon A2000, 3 parts of thixotropic synergist BYK-P 2720, 75 parts of spherical zinc powder (particle size 5 μm), 12 parts of propylene glycol methyl ether; the second component contains 80 parts by mass of 6520 Epoxy emulsion, 2 parts of W2N lithium magnesium silicate, 1 part of EXILVA cellulose, 1 part of BYK420 modified polyurea, 1 part of A200 fumed silicon, 5 parts of thixotropic blocking agent BYK-P 2710 and 10 parts of water.

[0049] The preparation method of the thick coating type waterborne e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com