Gelation-delayed in-situ polymerized water shutoff gel for high-temperature reservoirs

A technology of hydrogel and high-temperature oil, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of too fast gel formation, poor thermal stability, etc., and achieve convenient liquid dispensing, good thermal stability, and sealing High blocking strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

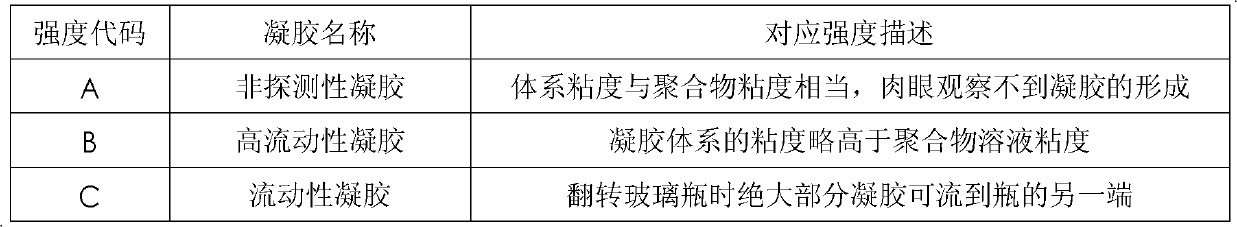

Image

Examples

Embodiment 1

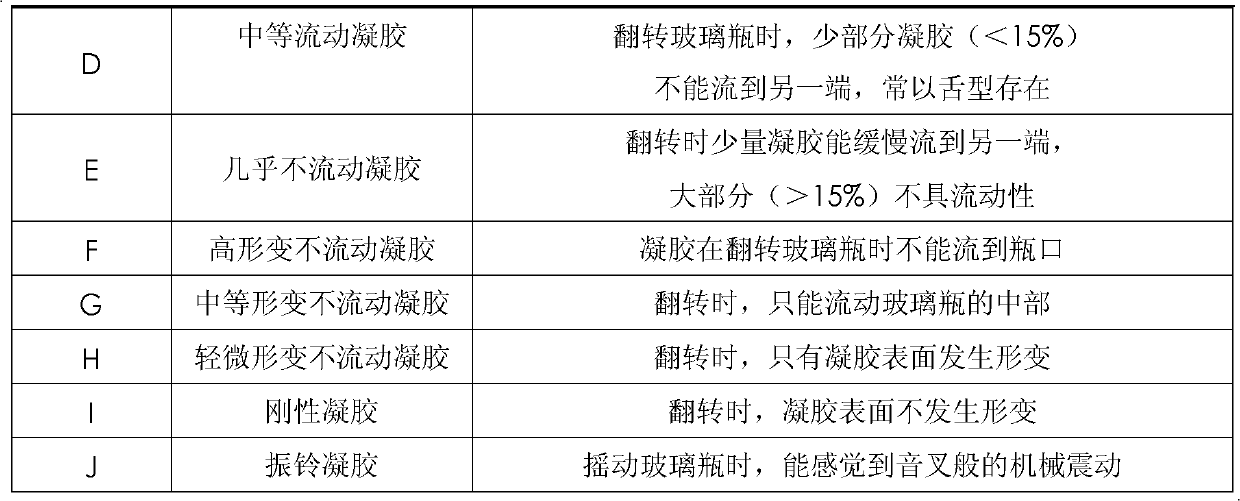

[0037] The total mass concentration of monomer A (acrylamide) and monomer B (butyl acetate) is 6%, wherein the mass ratio of A and B is 3:1, the concentration of crosslinking agent (phenolic resin) is 1%, and the solubilizer ( Methanol) concentration is 1.5%, initiator (ammonium persulfate) concentration variation range is 0.4~0.8%, and the rest is water. See Table 2 for the gelling conditions. The gelling time is between 30 and 40 hours, the final setting strength is grade I, and no syneresis occurs in 90 days.

[0038] Table 2 gelling situation of water blocking gel embodiment 1

[0039] Initiator(%)

Embodiment 2

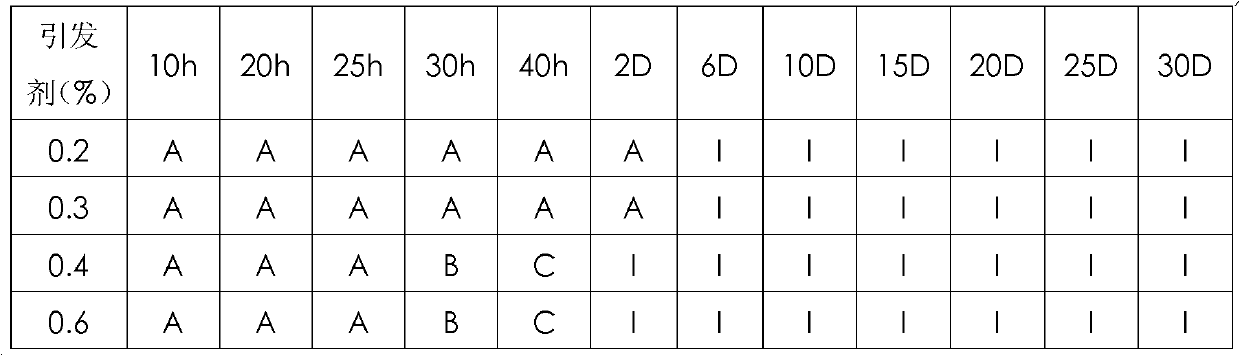

[0041] The total mass concentration of monomer A (acrylamide) and monomer B (allyl acetate + butyl acrylate, mass ratio: 1:1) is 6%, where the mass ratio of A and B is 4:1, and the crosslinking agent (Formaldehyde) concentration is 1%, solubilizer (ethanol+glycerol, mass ratio: 1:1) concentration is 1.5%, initiator (azobisisobutyronitrile (AIBN)) concentration variation range is 0.2~0.8% , and the rest is water. See Table 3 for the gelling conditions. The gelling time is between 40 and 72 hours, the final setting strength is grade I, and no syneresis occurs in 90 days.

[0042] Table 3 gelation situation of water blocking gel embodiment 2

[0043]

Embodiment 3

[0045] The mass concentration of the monomer is 6%, and the mass ratio of A (acrylamide) and B (ethyl methacrylate + allyl heptanoate + allyl phenoxyacetate, mass ratio: 1:1:1) is 4 : 1, solubilizer (isopropanol+n-butanol+tert-amyl alcohol, mass ratio: 1:1:1) concentration is 1.5%, initiator (potassium persulfate and tertiary amine monomer N, N-dimethyl The concentration of ethyl methacrylate) is 0.1%, the concentration range of the crosslinking agent (hexamethylenetetramine) is 1-2%, and the rest is water. See Table 4 for the gelling conditions. The gelling time is about 40 hours, the final setting strength is grade I, and no syneresis occurs in 90 days.

[0046] Table 4 Hydroplugging Gel Example 3 Gel-forming Situation

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com