Water-based formaldehyde-free adhesive as well as preparation method and application thereof

An adhesive and water-based technology, applied in the field of polymers, can solve the problems of short operation time, short pre-curing time, poor initial viscosity, etc., and achieve the effects of increased equipment investment, good initial viscosity, and long active cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

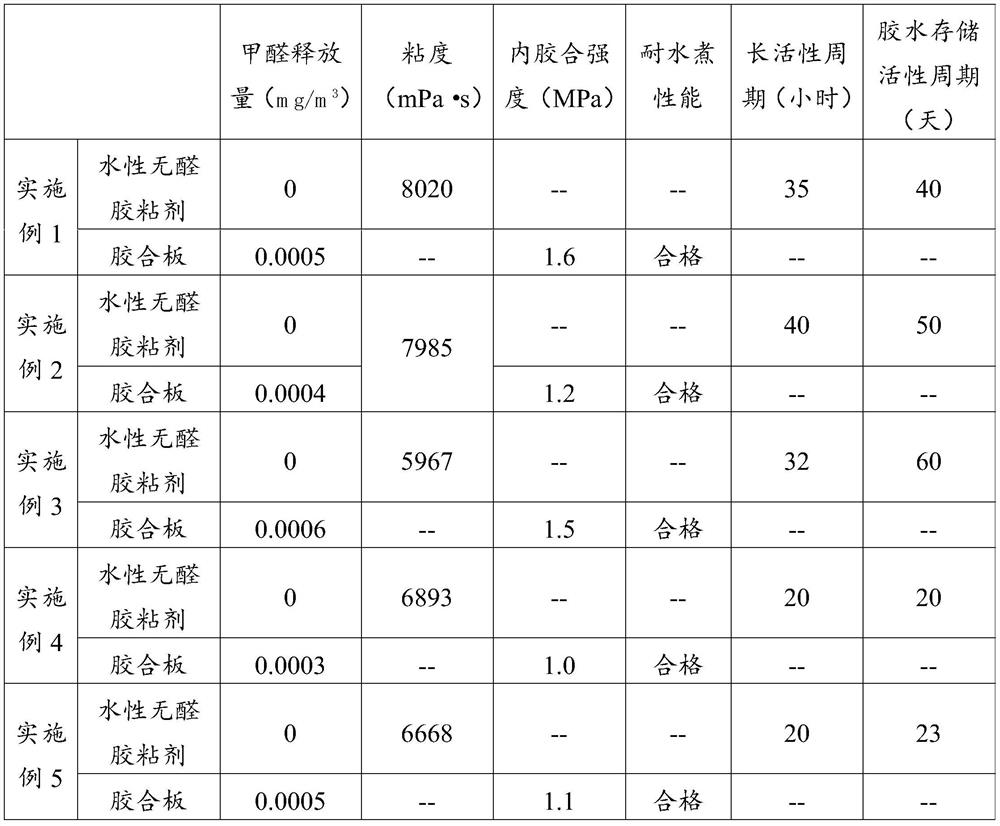

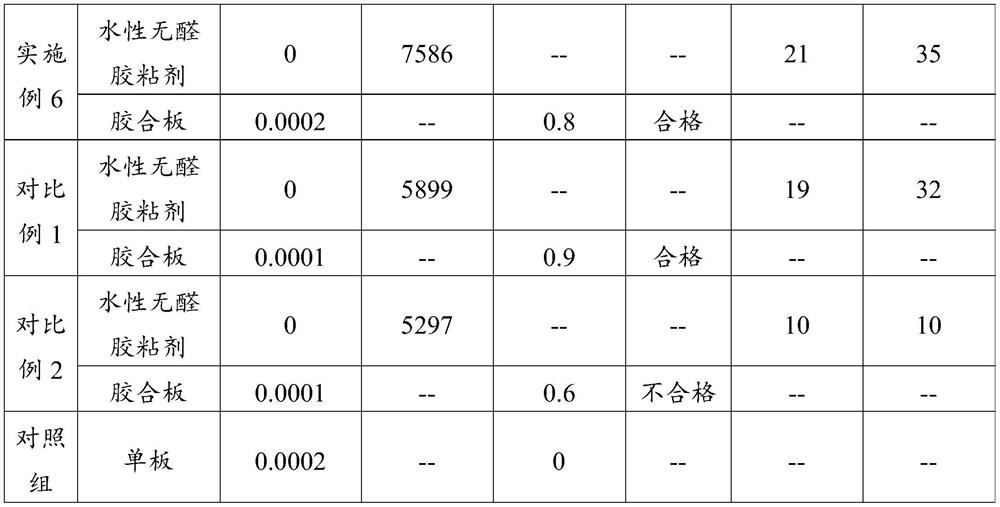

Examples

Embodiment 1

[0052] The preparation method of water-based formaldehyde-free adhesive described in the present embodiment comprises the steps:

[0053] (1) Dissolving polyvinyl alcohol in water at 100°C to obtain a high polymer solution, the mass concentration of the high polymer in the high polymer solution is 40%;

[0054] (2) Lower the temperature to 80°C, add sodium acetate to the polymer solution, adjust the pH value to 7, and stir the reaction for 10 hours under the conditions of nitrogen atmosphere, pressure 10MPa, and temperature 80°C to obtain a hydrogel glue;

[0055] (3) In a nitrogen atmosphere, under the conditions of a pressure of 8MPa and a temperature of 80°C, add vinyl acetate / acrylate copolymer emulsion and disodium lauryl sulfosuccinate monoester into the hydrogel, and then , React for 8 hours at a temperature of 0°C, adjust the pH value to 7 to form an emulsion / composite water-colloid system;

[0056] (4) After adding 1,6-hexamethylene diisocyanate and polyvinyl chlori...

Embodiment 2

[0063] The preparation method of water-based formaldehyde-free adhesive described in the present embodiment comprises the steps:

[0064] (1) Dissolving carboxymethyl cellulose in water at 50°C to obtain a polymer solution, the mass concentration of the polymer in the polymer solution is 30%;

[0065] (2) Lower the temperature to 20°C, add sodium silicate to the polymer solution, adjust the pH value to 2, and stir the reaction for 72 hours under the conditions of nitrogen atmosphere, pressure of -1MPa, and temperature of 0°C to obtain Hydrogel-like;

[0066] (3) In a nitrogen atmosphere, under the conditions of a pressure of 1 MPa and a temperature of 0 ° C, polyvinyl acetate emulsion and potassium monododecyl phosphate were added to the hydrogel, and then the pressure was 1 MPa, the temperature was 80 React for 12 hours under the condition of ℃, adjust the pH value to 12 to form an emulsion / composite water-colloid system;

[0067] (4) Add a water-soluble isocyanate adhesive...

Embodiment 3

[0074] The preparation method of water-based formaldehyde-free adhesive described in the present embodiment comprises the steps:

[0075] (1) Dissolving carboxymethyl cellulose in water at 200°C to obtain a polymer solution, the mass concentration of the polymer in the polymer solution is 0.1%;

[0076] (2) Adjust the temperature to 200°C, add sodium silicate to the polymer solution, adjust the pH value to 2, and stir the reaction for 0.1min under the conditions of nitrogen atmosphere, pressure 10MPa, and temperature 170°C to obtain the Hydrogels;

[0077] (3) In a nitrogen atmosphere, under the conditions of a pressure of -10MPa and a temperature of 250°C, add polyvinyl acetate emulsion and potassium monododecyl phosphate into the hydrogel, and then React at 200°C for 12 hours, adjust the pH value to 12 to form an emulsion / composite water-colloid system;

[0078] (4) Add a water-soluble isocyanate adhesive to the emulsion / composite water-gel system to adjust the pH value to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com