Process for manufacturing manganese ion corn flour adhesive

A corn flour and production process technology, applied in the directions of starch-derived adhesives, adhesive types, etc., can solve the problems of low initial viscosity, short storage time, environmental pollution, etc., and achieve good initial viscosity and high bonding strength. , good environmental effect

Inactive Publication Date: 2010-08-25

HARBIN BAISHUN PACKAGING

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Mainly used in corrugated cartons, pasting wallpapers, stamps, beer bottle labels, etc. Corrugated cartons are the most widely used packaging boxes. For many years, water glass glue has been used, which is easy to operate, but water glass cartons deliquesce when exposed to moisture, and the bonding speed is slow , not suitable for ocean transportation, has been gradually replaced by starch adhesives and synthetic polymer emulsion adhesives

Although the synthetic polymer emulsion adhesive has strong adhesion, fast film formation, and good water resistance, it is expensive, pollutes the environment, and is limited in use.

The starch adhesives produced on the market still have the disadvantages of slow drying, insufficient water resistance, short storage time, difficult process control, and low initial viscosity.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

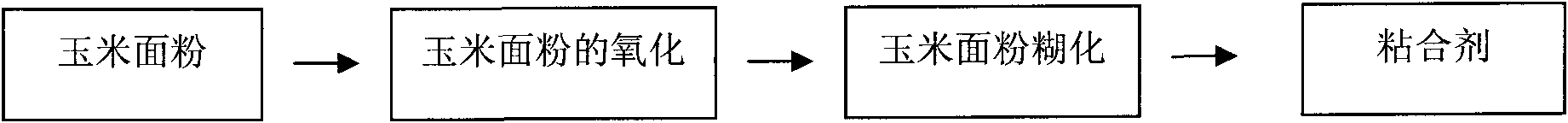

The invention discloses a process for manufacturing manganese ion corn flour adhesive, and relates to a natural high polymer adhesive. The process comprises the following steps: putting pretreated corn flour into a three-mouth bottle provided with a stirring device, adding 30 milliliters of water into the three-mouth bottle, stirring the mixture, adding hydrogen peroxide and potassium permanganate into the three-mouth bottle with stirring to perform oxidation, dripping 30 percent caustic soda solution after the mixture is oxidized for 30 to 40 minutes to continuously oxidize the mixture for 1 hour, dripping the rest alkali drips into the three-mouth bottle after the oxidation is finished, pasting the mixture for 30 minutes, adding borax into the three-mouth bottle, and continuously stirring the mixture for 10 minutes to obtain the manganese ion corn flour adhesive. The process has the advantages of low cost, good initial viscosity, quick drying, gelling resistance, high bonding strength, no toxicity and good environmental effect.

Description

Technical field: The invention relates to a natural polymer adhesive, in particular to a manufacturing process of a manganese ion corn flour adhesive. Background technique: At present, the raw materials of starch adhesives studied in our country are mainly potato, corn, sweet potato and other starches, which are synthesized by oxidation method. Mainly used in corrugated cartons, pasting wallpapers, stamps, beer bottle labels, etc. Corrugated cartons are the most widely used packaging boxes. For many years, water glass glue has been used, which is easy to operate, but water glass cartons deliquesce when exposed to moisture, and the bonding speed is slow , which is not suitable for the needs of ocean transportation, has been gradually replaced by starch adhesives and synthetic polymer emulsion adhesives. Although the synthetic polymer emulsion binder has strong adhesive force, fast film formation and good water resistance, it has high cost, pollutes the environment and is lim...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J103/10

Inventor 房金星

Owner HARBIN BAISHUN PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com