Method for producing composite SSL-UF urea-formaldehyde resin glue

A technology of urea-formaldehyde resin glue and production method, which is applied in the direction of adhesive types, adhesives, aldehyde/ketone condensation polymer adhesives, etc., and can solve problems such as environmental pollution, poor aging resistance, and unsatisfactory adhesive performance. , achieve cost reduction and high initial viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

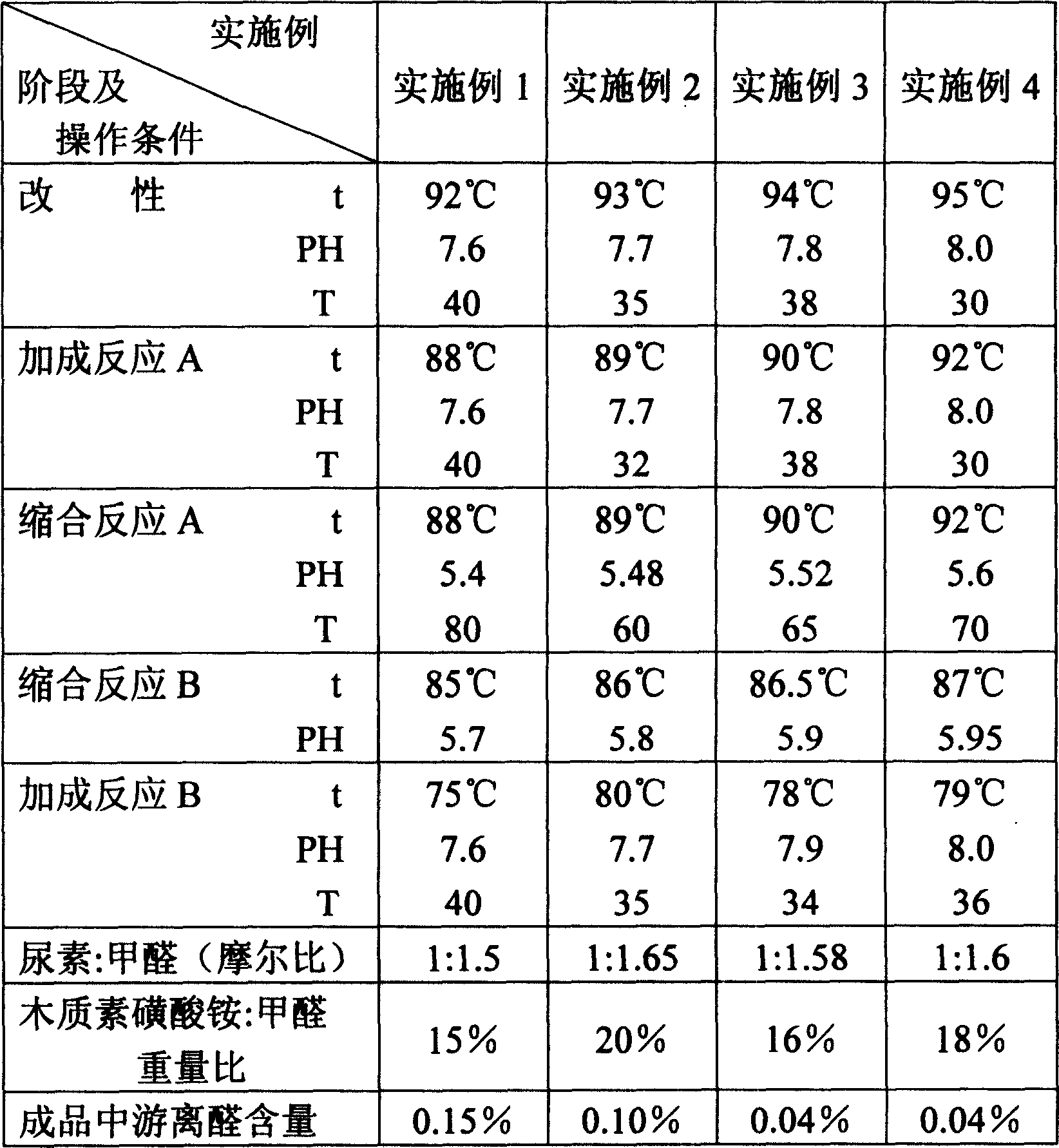

Examples

Embodiment Construction

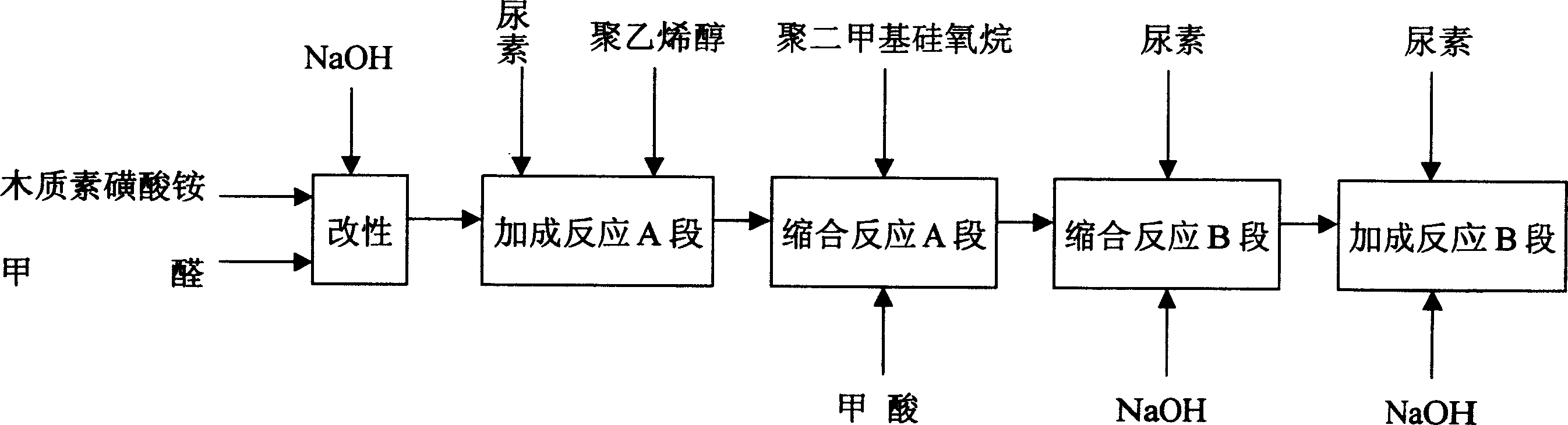

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

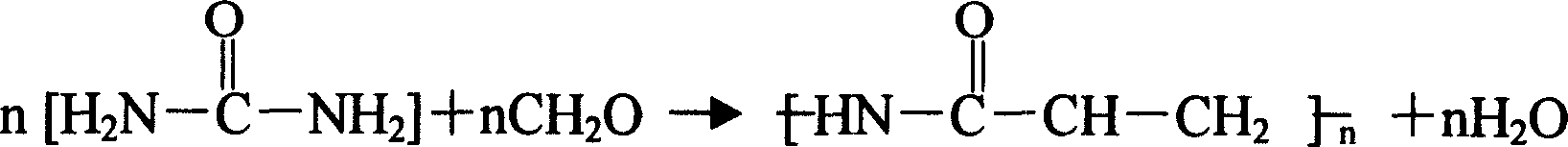

[0017] The production process of the present invention is carried out in a reaction kettle, which is stirred by a stirrer inside the kettle, and jacketed outside the kettle, through which steam is passed for heating and water is passed for cooling. The urea-formaldehyde generation reaction is

[0018]

[0019] One of the features of the present invention is that ammonium lignosulfonate SSL binder is added in the reaction, which is an excellent formaldehyde absorbent, so dehydration is not necessary in the production process, which is the cause of the pollution of formaldehyde-free water waste liquid, and is also the cause of free aldehyde in the product. The reason for the low content is that ammonium lignosulfonate SSL is added, and the sugar content in ammonium lignosulfonate must be guaranteed to be 6% to 8%. The significance lies in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com