Thickening composition for adhesive for plywood and preparation method of thickening composition

An adhesive and plywood technology, applied in the directions of adhesives, adhesive types, starch adhesives, etc., can solve the problems of consuming large food resources and increasing the cost of raw materials, and achieve the advantages of good adsorption, simple use and lower production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

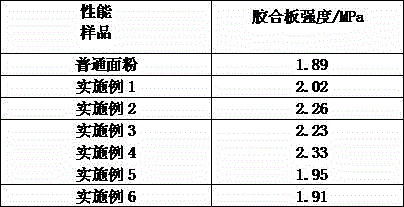

Examples

Embodiment 1

[0025] The thickening composition of the adhesive for plywood of the present invention is made of the raw materials comprising the following parts by weight:

[0026] 60 kg of flour, 30 kg of lignin, 30 kg of cassava flour, 3 kg of polyvinyl alcohol, 3 kg of silicoaluminide, and 5 kg of antifungal agent.

[0027] Described fungicide is phenol.

[0028] The silicoaluminide is aluminosilicate.

[0029] The preparation method of the thickening composition of adhesive for plywood of the present invention comprises the following steps:

[0030] A. Heat polyvinyl alcohol;

[0031] B. Mix flour, lignin, tapioca flour, and silicoaluminide in proportion to obtain a mixture;

[0032] C. Add an antifungal agent to the mixture in step B, then add polyvinyl alcohol dropwise while stirring, and stir well to obtain.

[0033] The stirring time in the step C is 20 minutes.

Embodiment 2

[0035] The thickening composition of the adhesive for plywood of the present invention is made of the raw materials comprising the following parts by weight:

[0036] 70 kg of flour, 40 kg of lignin, 40 kg of cassava flour, 4 kg of polyvinyl alcohol, 4 kg of silicoaluminide, and 6 kg of antifungal agent.

[0037] Described fungicide is pentachlorophenol.

[0038] The silicoaluminide is aluminosilicate.

[0039] The preparation method of the thickening composition of adhesive for plywood of the present invention comprises the following steps:

[0040] A. Heat polyvinyl alcohol;

[0041] B. Mix flour, lignin, tapioca flour, and silicoaluminide in proportion to obtain a mixture;

[0042] C. Add an antifungal agent to the mixture in step B, then add polyvinyl alcohol dropwise while stirring, and stir well to obtain.

[0043] The stirring time in the described step C is 25 minutes.

Embodiment 3

[0045] The thickening composition of the adhesive for plywood of the present invention is made of the raw materials comprising the following parts by weight:

[0046] 80 kg of flour, 50 kg of lignin, 50 kg of cassava flour, 5 kg of polyvinyl alcohol, 5 kg of silicoaluminide, and 7 kg of antifungal agent.

[0047] The antifungal agent is copper 8-hydroxyquinolate.

[0048] The silicoaluminide is aluminosilicate.

[0049] The preparation method of the thickening composition of adhesive for plywood of the present invention comprises the following steps:

[0050] A. Heat polyvinyl alcohol;

[0051] B. Mix flour, lignin, tapioca flour, and silicoaluminide in proportion to obtain a mixture;

[0052] C. Add an antifungal agent to the mixture in step B, then add polyvinyl alcohol dropwise while stirring, and stir well to obtain.

[0053] The stirring time in the step C is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com