Masonry mortar plasticizer and preparation method thereof

A masonry mortar and plasticizer technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as complex composition, surface water and groundwater pollution, and great harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

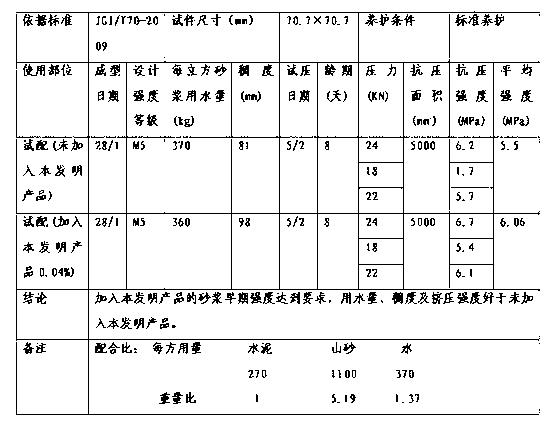

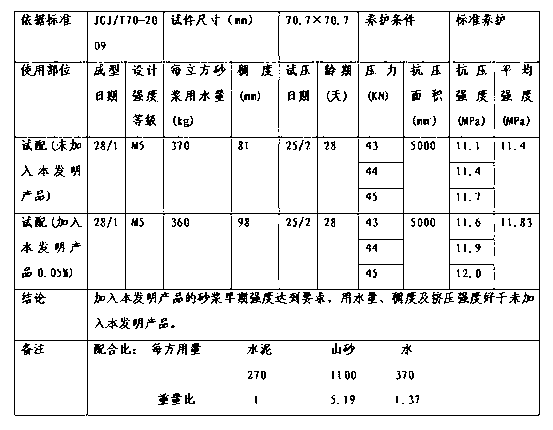

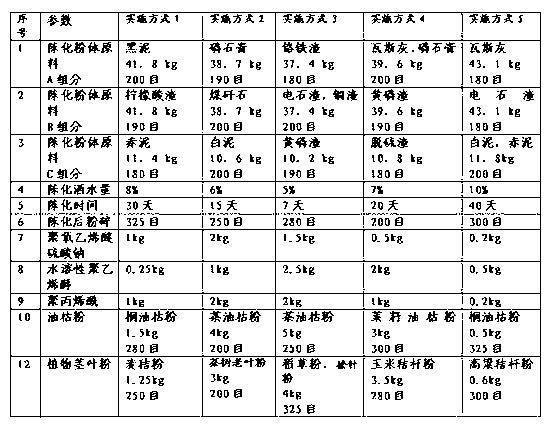

[0027] The specific parameters of each embodiment of the masonry mortar plasticizer preparation method are shown in Table 1, and the masonry mortar plasticizer is made up of the following raw materials in weight percentage:

[0028] Aging powder 85-98%, polyoxyethylene ether sodium sulfate 0.2-2%, water-soluble polyvinyl alcohol 0.25-2.5%, polyacrylamide 0.2-2%, oil dry powder 0.5-5%, plant stem and leaf powder 0.36-4%;

[0029] in,

[0030] (1) The aging powder is composed of components A, B and C: A:B:C=4:4:1;

[0031] Component A is: at least one of black mud, chromium slag, phosphogypsum, and gas ash; the black mud is waste residue filtered from papermaking industrial wastewater; the chromium slag is used to produce metallic chromium and chromium salts The industrial waste slag produced in the process; the phosphogypsum is the solid waste slag produced in the production of phosphoric acid; the gas ash is the excrement of the blast furnace ironmaking process.

[0032] Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com