Mixed loading emulsion explosive used for upward hole charge and preparation method of mixed loading emulsion explosive

A technology of emulsified explosives and mixed packaging, which is applied in the direction of explosives processing equipment, explosives, explosives composite components, etc., can solve the problems of falling powder, slow cross-linking speed, waste of resources, etc., and achieve the goal of saving resources, reducing material waste, and saving energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

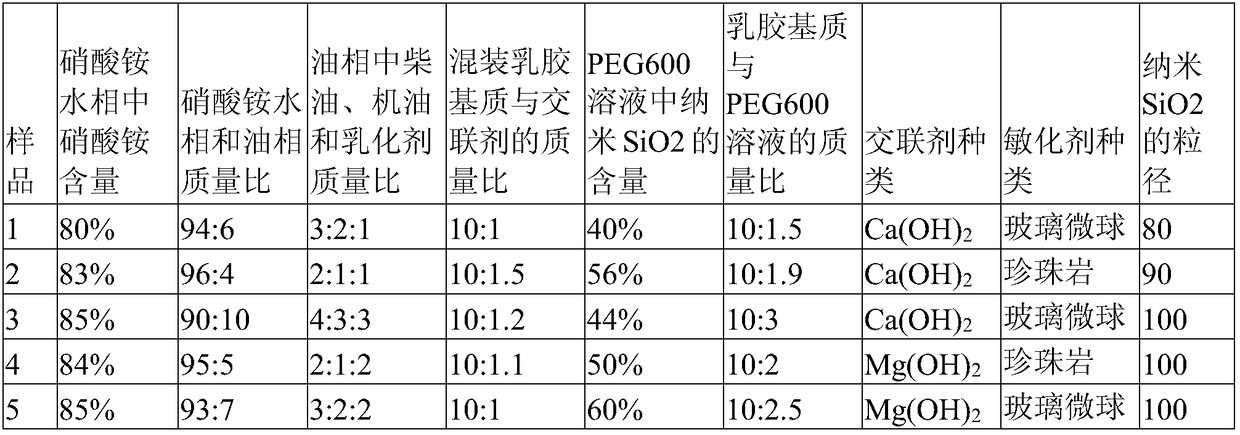

[0023] To prepare mixed emulsion explosives for upward hole charging, follow the steps below:

[0024] (1) Prepare mixed latex matrix: heat the water phase of ammonium nitrate with a mass content of 80 to 85% to 88°C to 98°C, take the oil phase and heat it to 55°C to 60°C, and heat the heated ammonium nitrate water phase and oil The phases are mixed according to the mass ratio of 90-96:4-10, stirred under high shear conditions, and the mixed latex matrix is prepared through the ground pharmaceutical module; the oil phase is composed of diesel oil, engine oil and polyisobutylene succinic anhydride alcohol The amine emulsifier is obtained by mixing according to the mass ratio of 2-4:1-3:1-3;

[0025] (2) Mix latex matrix and cross-linking agent: mix the latex matrix obtained in step (1) with cross-linking agent through underground charging equipment at 55°C to 60°C, and mix latex matrix and cross-linking agent The mass ratio is 10:1~1.5;

[0026] (3) PEG / SiO2 2 Shear thicke...

Embodiment 2

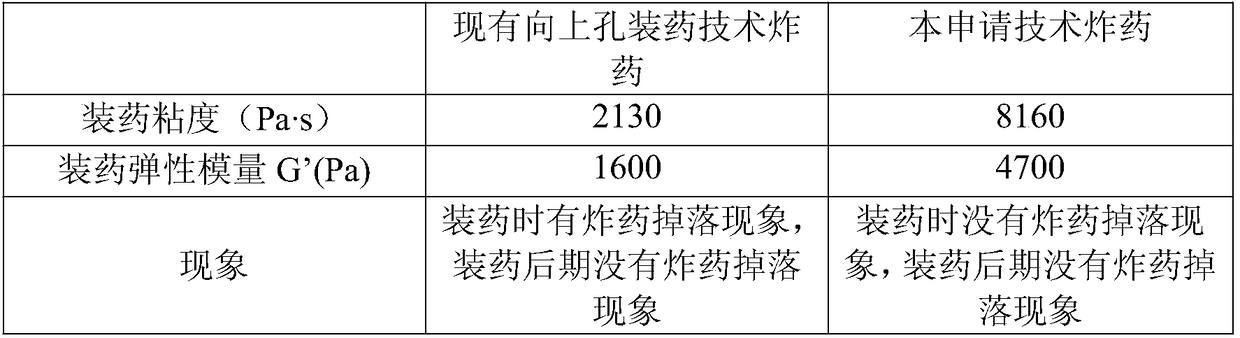

[0032] The mixed emulsified explosive samples 1-5 obtained in Example 1 are charged with high initial viscosity, combined with cross-linking and solidification, the emulsified explosive is not easy to fall out of the charge hole, reduces material waste, and saves energy and resources. The explosives prepared by the application method are compared with the emulsion explosives of our company's original on-site upward filling of deep holes, and the relevant indicators are shown in the following table 2:

[0033] Table 2. Comparison of the charging effects of the two technologies

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com