Nanometer composite polyvinyl alcohol adhesive and its preparation method

A polyvinyl alcohol and nano-composite technology, applied in the direction of adhesive types, unsaturated alcohol copolymer adhesives, etc., can solve the problems of low adhesive force, pollute the environment, high cost, improve the adhesive strength, eliminate the Environmental pollution, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

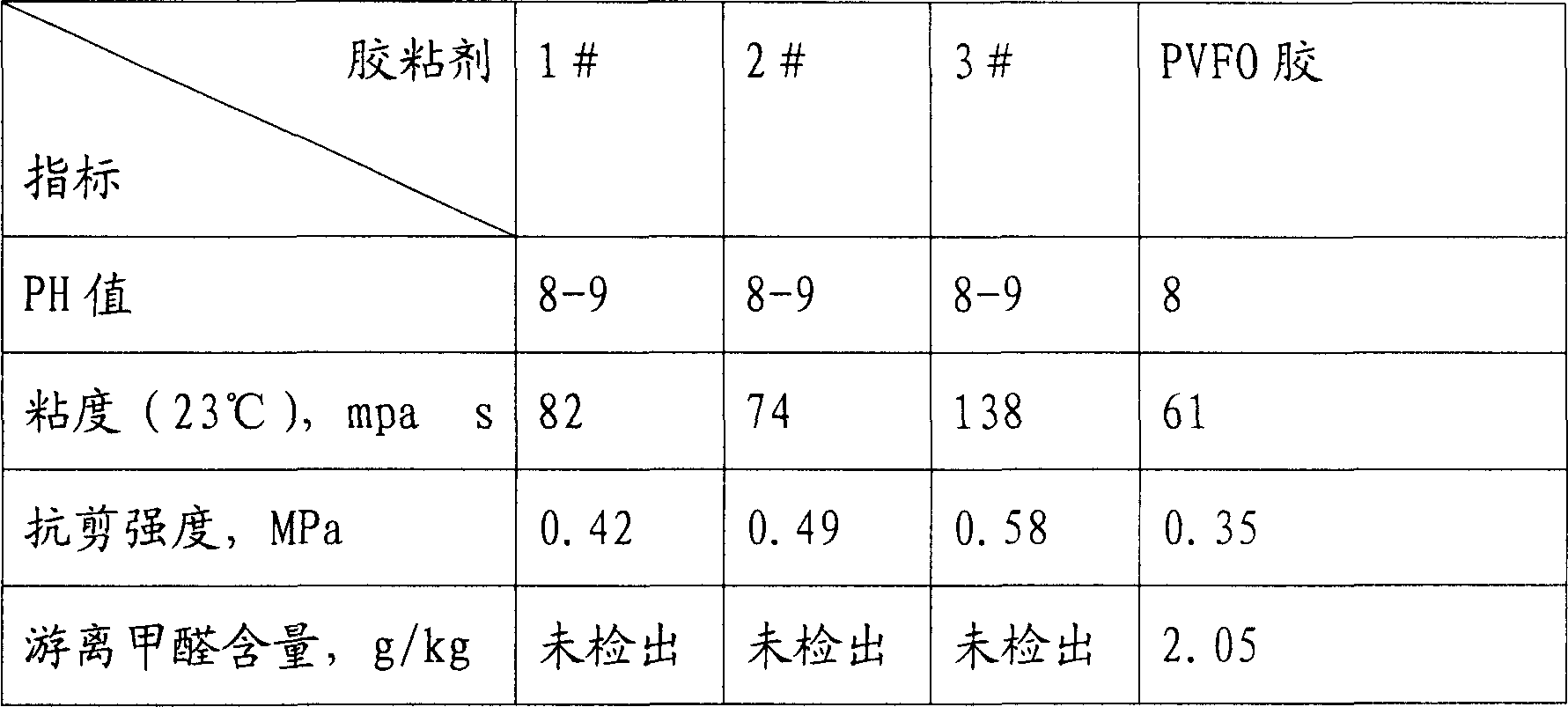

Examples

Embodiment 1

[0019] Mix 100kg of nanocomposite polyvinyl alcohol adhesive, take 1.5kg of polyvinyl alcohol, 2.4kg of nano-scale attapulgite, and 96.1kg of water, add all these materials into the reaction bottle, and stir at a rate of 40-50 rpm at room temperature Evenly, heat up to 90-98°C, stir at a speed of 60-70 rpm for 0.5-1 hour, and discharge to obtain a nanocomposite polyvinyl alcohol adhesive. The adhesive can be used for bonding paper / polyester cloth composite materials.

[0020] The molecular formula of polyvinyl alcohol is: (CH 2 CHOH) n

[0021] The molecular formula of attapulgite is: MgAl 5 Si 8 o 20 (OH) 2 (OH 2 ) 4 4H 2 o

Embodiment 2

[0023] Mix 100kg of nanocomposite polyvinyl alcohol adhesive, take 1.5kg of polyvinyl alcohol, 3kg of nano-scale attapulgite, and 95.5kg of water, add all these materials into the reaction bottle, and stir evenly at a rate of 40-50 rpm at room temperature , heat up to 90-98° C., stir at a speed of 60-70 rpm for 0.5-1 hour, and discharge to obtain a nanocomposite polyvinyl alcohol adhesive. The finished adhesive is used for bonding wall coverings.

Embodiment 3

[0025] Mix 100kg of nanocomposite polyvinyl alcohol adhesive, take 2kg of polyvinyl alcohol, 3kg of nano-scale attapulgite, and 95kg of water, add all these materials into the reaction bottle, stir evenly at a rate of 40-50 rpm at room temperature, and heat up to 90-98° C., stirred at a rate of 60-70 rpm for 0.5-1 hour, and discharged to obtain a nanocomposite polyvinyl alcohol adhesive. The prepared adhesive is used for the bonding of plywood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com