Environmental-friendly double-component polyurethane adhesive

A two-component polyurethane and adhesive technology, applied in the field of polyurethane, can solve the problems of long-term curing instability, poor aging resistance, unfavorable environmental protection, etc., and achieve adjustable opening time, high stability, and long storage period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

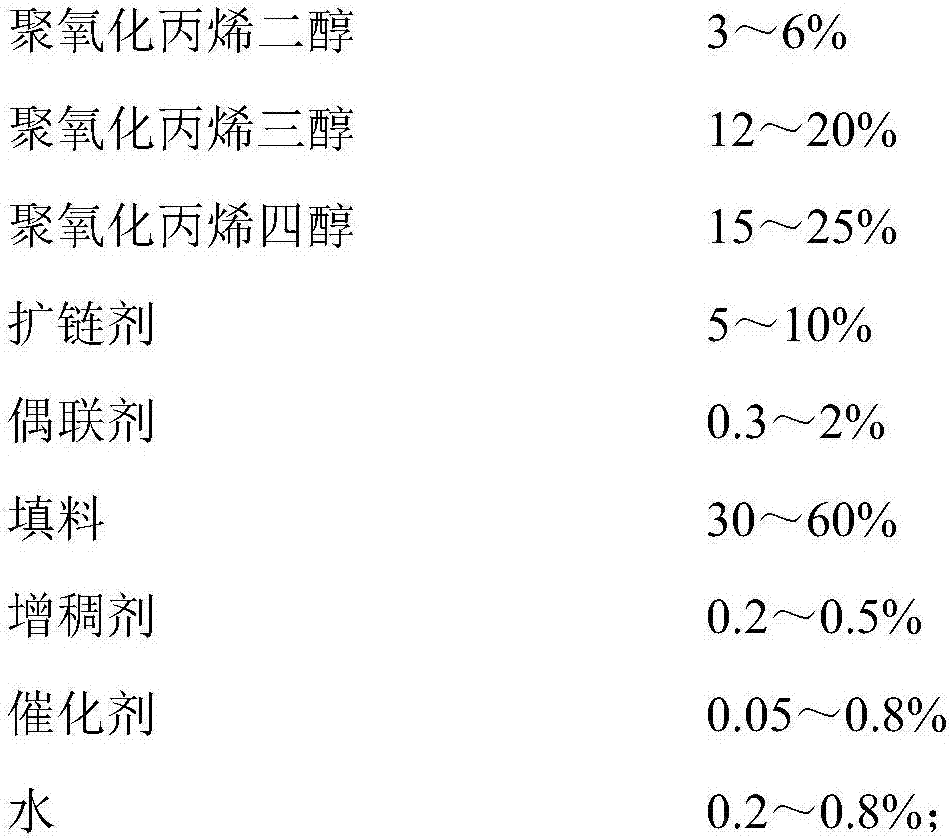

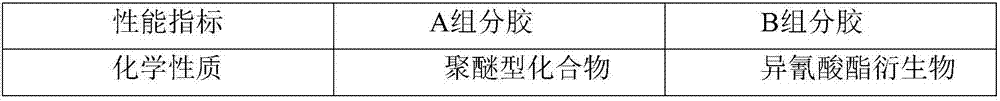

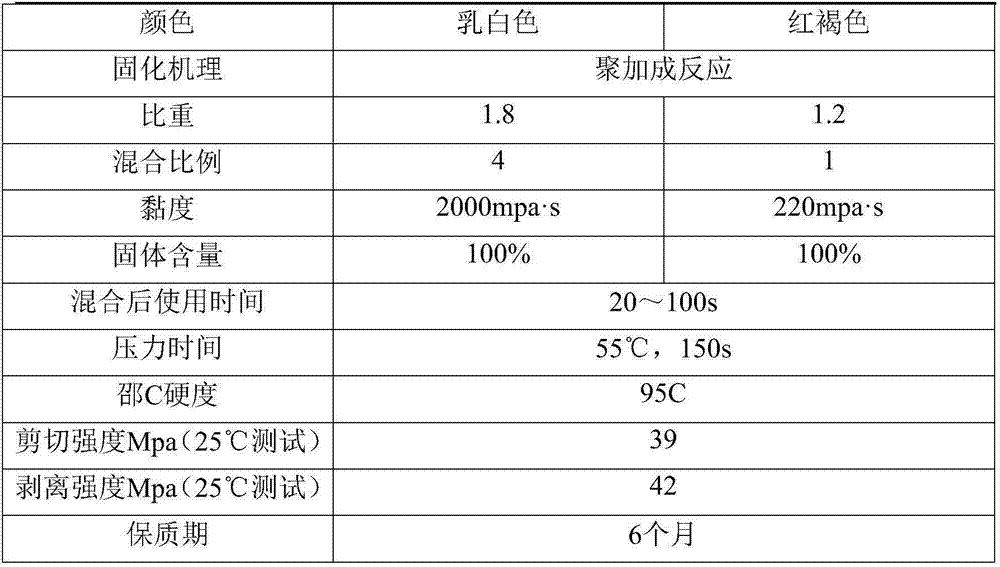

[0024] Component A: Weigh 30 kg of polyoxypropylene diol with a molecular weight of 1000, 75 kg of polyoxypropylene triol with a molecular weight of 5000, 145 kg of polyoxypropylene tetraol with a molecular weight of 600, and polyoxypropylene with a molecular weight of 300 in a 1000L reactor. Propylene triol 45kg, thickener fumed silica (AEROSIL R202) 1.5kg, silane coupling agent (KH550) 3kg, calcium carbonate powder 295kg, catalyst dibutyltin laurate and triethylene diammonium (33% concentration) 2.4kg , 2.4kg of water, dispersed at 200rpm for 100min, and discharged;

[0025] Component B: Weigh 150kg and 141kg of diphenylmethylene diisocyanate and polymethylene polyphenylisocyanate respectively, 9kg of dibutyl phthalate, disperse at 200rpm for 20min, and control the NCO% at 25-30 %,Discharge;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com