Method for improving viscosity stability of oil field polymer flooding

A viscosity stability, polymer technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of high usage of hexamethylenetetramine, reduce the formation of hydroxyl radicals, reduce losses, The effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

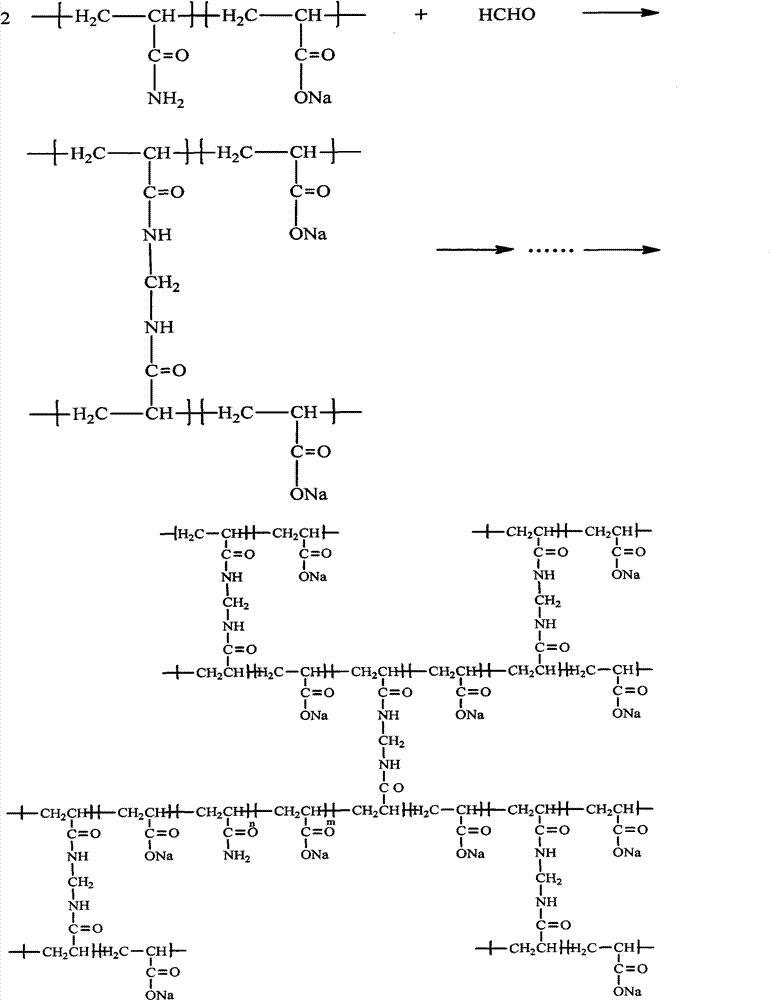

Method used

Image

Examples

Embodiment 1

[0025] Polyacrylamide: The molecular weight is 18 million, and the degree of hydrolysis is 26%.

[0026] Polymerized water: the total salinity is 362mg / L, Na + 、K + The concentration is 79.2mg / L, Ca 2+ The concentration is 23.4mg / L, Mg 2+ The concentration is 9.5mg / L, Cl - The concentration is 104mg / L, SO 4 2- The concentration is 20mg / L, HCO 3 - An aqueous solution with a concentration of 126mg / L and a pH value of 7.8.

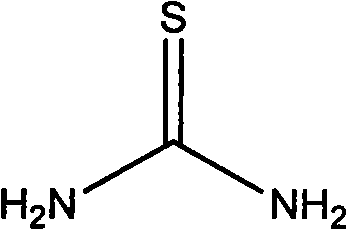

[0027] Experimental method: at room temperature, add 50mg / L thiourea to the polycondensation water, stir for 2 hours, and let it stand for 1 hour; Stir in poly water, the initial stirring speed is 300 rpm, after the polymer particles are fully dispersed, control the stirring speed at 120 rpm, stir for 2 hours, and let stand for 6 hours, and finally prepare a concentration of 1500mg / min The polymer solution of L; add hexamethylenetetramine in the polymer solution, make the concentration of hexamethylenetetramine in the solution reach 150mg / L, stir 0.5...

Embodiment 2

[0030] Polyacrylamide and polyhydric conditions are the same as in Example 1.

[0031] The experimental method is the same as in Example 1, but the concentration of thiourea added to the polycondensation water reaches 100mg / L. The viscosity retention rate of the obtained sample after storage at 80° C. for 30 days was 56.0%.

Embodiment 3

[0033] Polyacrylamide and polyhydric conditions are the same as in Example 1.

[0034] The experimental method is the same as in Example 1, but the concentration of thiourea added to the polycondensation water reaches 150mg / L. The viscosity retention rate of the obtained sample after storage at 80° C. for 30 days was 93.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com