Corrugated paper adhesive and preparation method thereof

A technology of adhesive glue and corrugated paper, applied in the field of adhesive glue, can solve problems affecting the normal use of corrugated cardboard and corrugated boxes, poor stability of adhesive glue, unstable viscosity, etc. The effect of high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

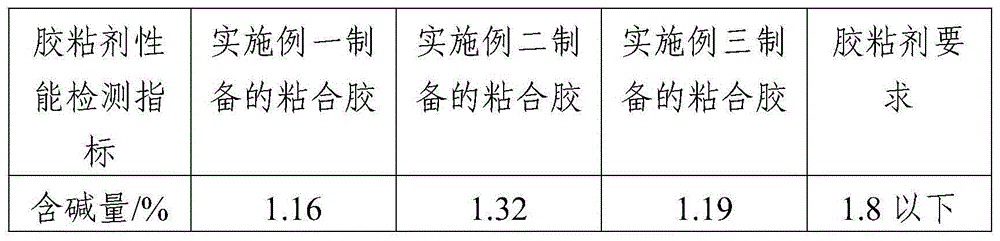

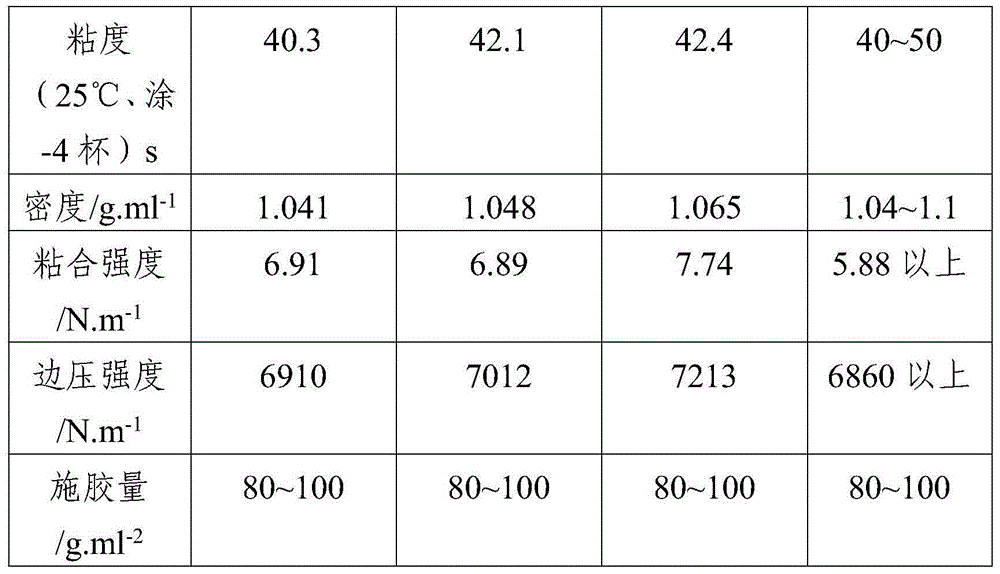

Examples

Embodiment 1

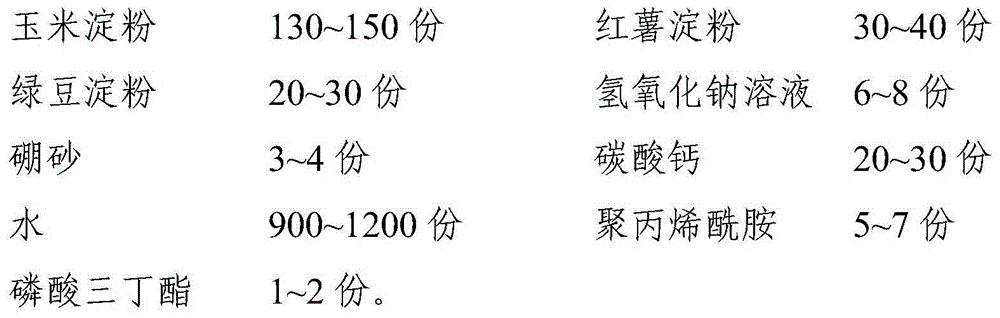

[0029] raw material:

[0030] Corn starch 130kg, sweet potato starch 30kg, mung bean starch 20kg, sodium hydroxide solution 6kg, borax 3kg, calcium carbonate 20kg, water 900kg, polyacrylamide 5kg and tributyl phosphate 1kg.

[0031] Preparation:

[0032] (1) Add water into the mixing tank, heat up to 50°C, then add cornstarch and sodium hydroxide solution, keep stirring at constant temperature for 10 minutes, and control the rotation speed to 3000 rpm;

[0033] (2) Add mung bean starch and sweet potato starch in the mixing tank, continue to keep constant temperature and stir for 15min, and control the rotating speed to be 3000 rpm;

[0034] (3) Then add calcium carbonate, tributyl phosphate, borax and polyacrylamide, raise the temperature to 70°C, control the rotation speed to 3000 rpm, keep stirring at constant temperature for 15 minutes, and then stop heating to obtain the finished adhesive glue .

Embodiment 2

[0036] raw material:

[0037] Corn starch 150kg, sweet potato starch 40kg, mung bean starch 30kg, sodium hydroxide solution 8kg, borax 4kg, calcium carbonate 30kg, water 1200kg, polyacrylamide 7kg and tributyl phosphate 2kg.

[0038] Preparation:

[0039] (1) Add water into the mixing tank, heat up to 60°C, then add cornstarch and sodium hydroxide solution, keep stirring at constant temperature for 6 minutes, and control the speed at 3000 rpm;

[0040] (2) Add mung bean starch and sweet potato starch in the mixing tank, continue to keep stirring at a constant temperature for 10 minutes, and control the rotating speed to be 3000 rpm;

[0041] (3) Add calcium carbonate, tributyl phosphate, borax and polyacrylamide, raise the temperature to 80°C, control the rotation speed to 3000 rpm, keep stirring at constant temperature for 10 minutes, and then stop heating to obtain the finished adhesive glue .

Embodiment 3

[0043] raw material:

[0044] Corn starch 140kg, sweet potato starch 35kg, mung bean starch 25kg, sodium hydroxide solution 7kg, borax 3.5kg, calcium carbonate 25kg, water 1000kg, polyacrylamide 6kg and tributyl phosphate 1.5kg.

[0045] Preparation:

[0046] (1) Add water into the mixing tank, heat up to 55°C, then add cornstarch and sodium hydroxide solution, keep stirring at constant temperature for 8 minutes, and control the rotation speed to 3000 rpm;

[0047] (2) Add mung bean starch and sweet potato starch in the mixing tank, continue to keep stirring at constant temperature for 12min, and control the rotating speed to be 3000 rpm;

[0048] (3) Add calcium carbonate, tributyl phosphate, borax and polyacrylamide, raise the temperature to 75°C, keep stirring at a constant temperature for 12 minutes, control the speed at 3000 rpm, and then stop heating to obtain the adhesive finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com