Aqueous sealing adhesive emulsion and preparation method thereof

A sealing glue, water-based technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve the problems of enterprise loss, water-based sealing glue bonding strength, poor high temperature and low temperature resistance, easy degumming, etc. Achieve the effect of high initial viscosity, good frost resistance and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

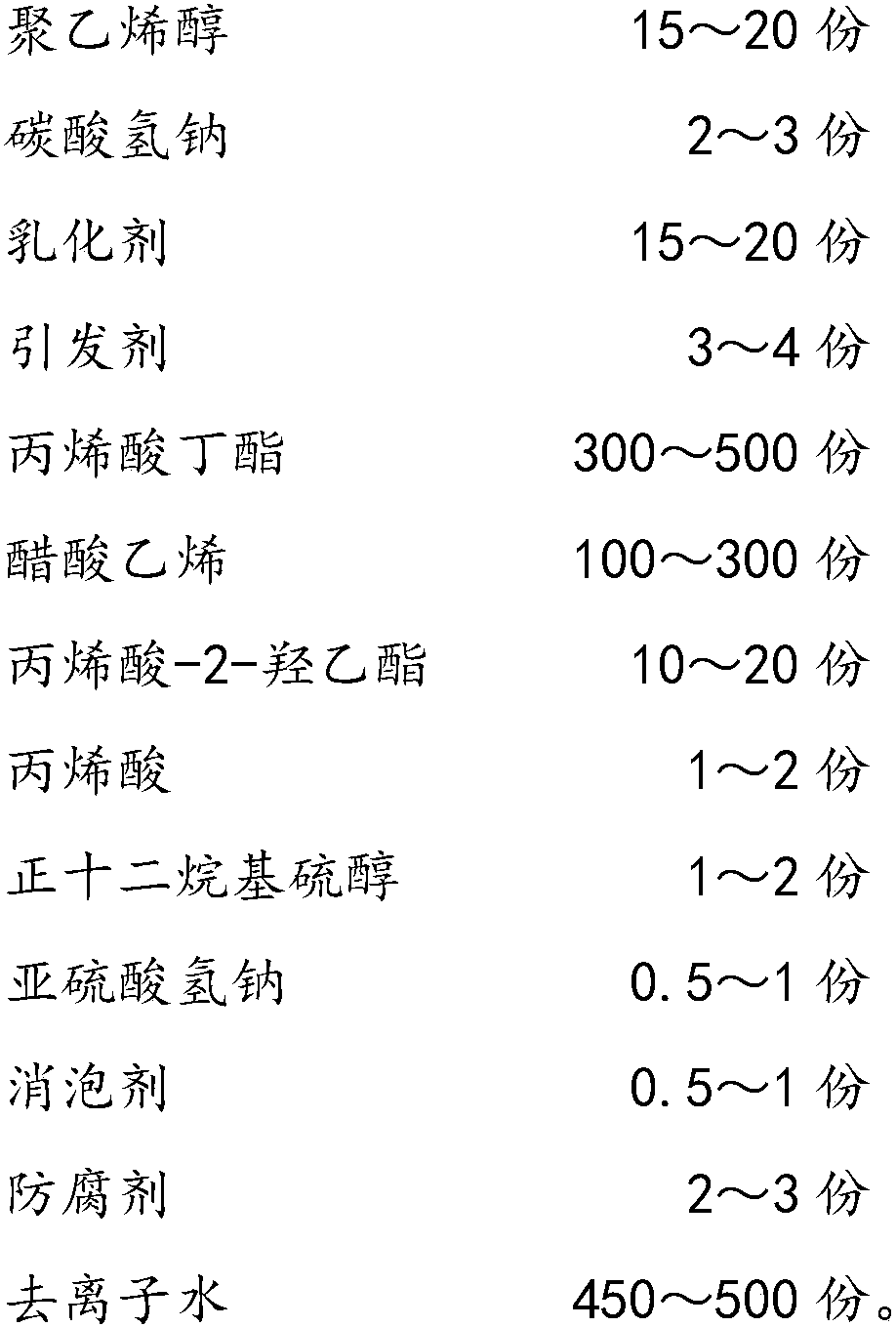

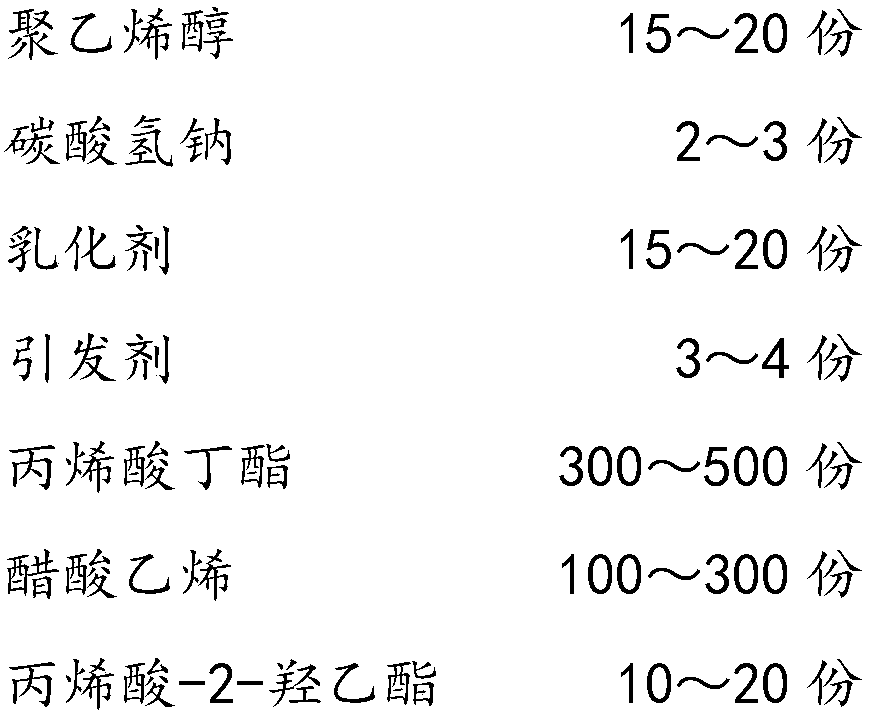

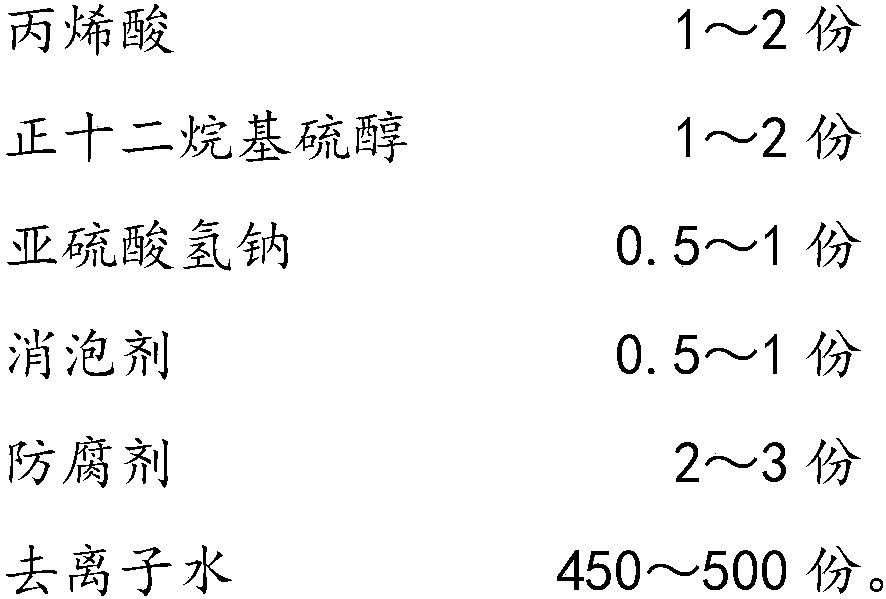

[0026] 1) Weighing of raw materials:

[0027]

[0028]

[0029] 2) Preparation process:

[0030] Dissolve 0.5kg of initiator in 5kg of water to obtain initial initiator; dissolve 2.5kg of initiator in 45kg of water to obtain drip initiator; dissolve 0.2kg of initiator in 5kg of water to obtain post-initiator; Sodium hydrogen is dissolved in 10kg of water to obtain a reducing agent.

[0031] Mix and stir 310kg of butyl acrylate, 240kg of vinyl acetate, 15kg of 2-hydroxyethyl acrylate, 1kg of acrylic acid, and 1.2kg of n-dodecyl mercaptan to obtain a mixed monomer.

[0032] Add 420kg of water and 17.5kg of polyvinyl alcohol into the reactor, start stirring, raise the temperature to 92°C, stir and disperse the polyvinyl alcohol until it is completely dissolved.

[0033] Lower the temperature, keep the temperature between 75 and 80°C, add 2.2kg of sodium bicarbonate, 18kg of emulsifier and initial initiator in sequence, then add the mixed monomer and initiator dropwise at ...

Embodiment 2

[0038] 1) Weighing of raw materials:

[0039]

[0040] 2) Preparation process:

[0041] Dissolve 0.5kg of initiator in 5kg of water to obtain initial initiator; dissolve 2.5kg of initiator in 45kg of water to obtain drip initiator; dissolve 0.2kg of initiator in 5kg of water to obtain post-initiator; Sodium hydrogen is dissolved in 10kg of water to obtain a reducing agent.

[0042] Mix and stir 400 kg butyl acrylate, 150 kg vinyl acetate, 15 kg 2-hydroxyethyl acrylate, 1 kg acrylic acid, and 1.2 kg n-dodecyl mercaptan to obtain a mixed monomer.

[0043] Add 420kg of water and 17.5kg of polyvinyl alcohol into the reactor, start stirring, raise the temperature to 92°C, stir and disperse the polyvinyl alcohol until it is completely dissolved.

[0044] Lower the temperature, keep the temperature between 75 and 80°C, add 2.2kg of sodium bicarbonate, 18kg of emulsifier and initial initiator in sequence, then add the mixed monomer and initiator dropwise at a constant speed for 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com