Bi-component polyurethane structural adhesive for bonding power batteries and preparation method thereof

A two-component polyurethane and power battery technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problem of difficult to meet the requirements of adhesive performance and toughness at the same time, poor storage stability, and hard structure segment increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention provides a method for preparing a two-component polyurethane structural adhesive for bonding power batteries described in the above technical solution, comprising the following steps:

[0051] Mix 40-65 parts of polymethylene polyphenylisocyanate, 30-50 parts of aluminum hydroxide, 2-5 parts of hydrophobic fumed silica, and 0-5 parts of plasticizer to obtain component A;

[0052] Mix 40-65 parts of bio-based polyol, 1-4 parts of fumed silica, 20-50 parts of flame retardant, 1-5 parts of adhesion promoter and 0.01-0.5 parts of catalyst to obtain component B;

[0053] The A component and the B component are mixed to obtain a two-component polyurethane structural adhesive for power battery bonding.

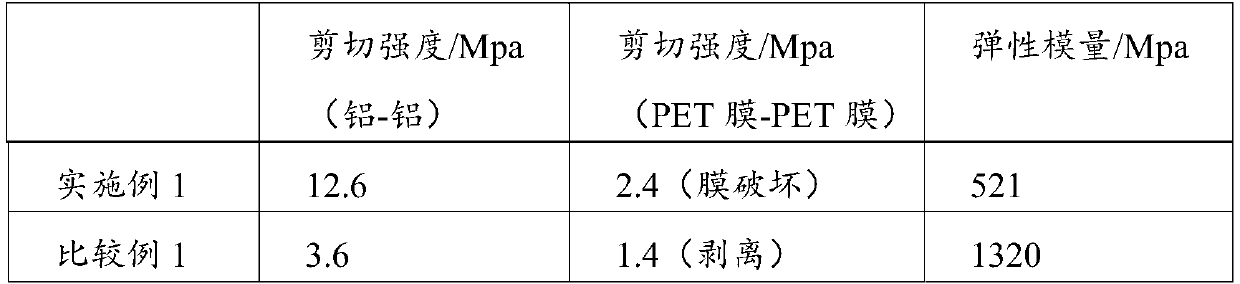

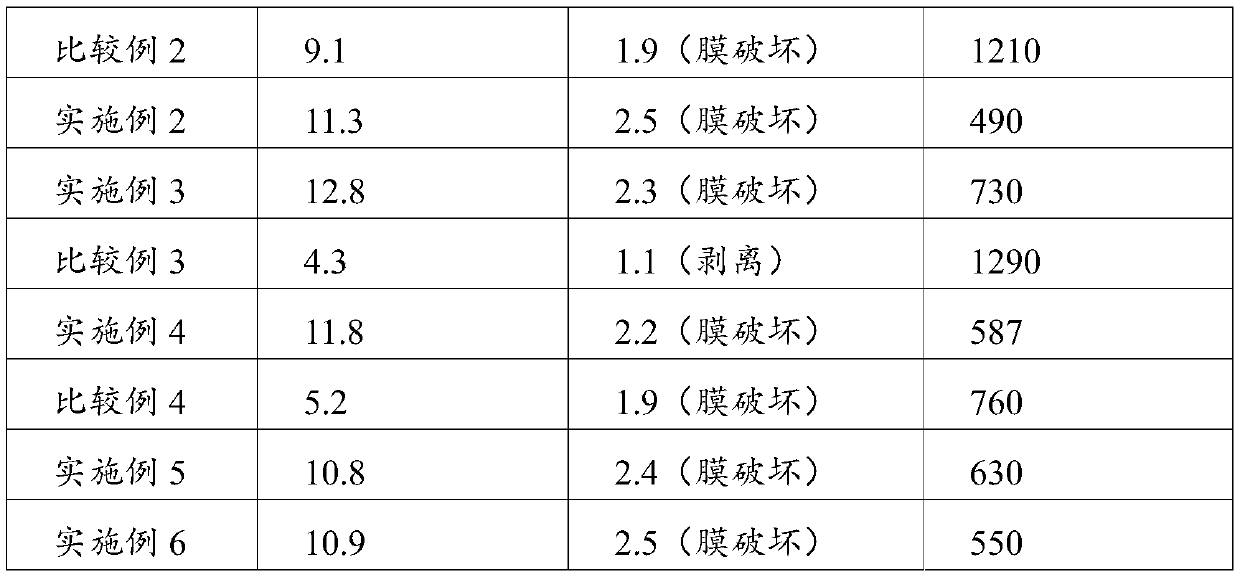

[0054] The present invention tests the shear strength and elastic modulus of the two-component polyurethane structural adhesive for bonding the power battery described in the above technical solution:

[0055] Shear strength test method: Use unpolished a...

Embodiment 1

[0059] Preparation of Adhesion Promoter:

[0060] Add 255g of N-phenyl-γ-aminopropyltrimethoxysilane into a three-necked flask, stir, heat up to 40°C, add 164g of p-cresyl glycidyl ether, stir and react at 40°C for 2 hours, then cool down and discharge to obtain Adhesion promoter.

[0061] Preparation of component A:

[0062] Add 520g of polymethylene polyphenyl isocyanate PM100, 420g of aluminum hydroxide, 30g of Wacker H18 hydrophobic silica, and 30g of tricresyl phosphate into a planetary mixer, stir and disperse for 2 hours, and obtain component A with a viscosity of about 15Pa· s.

[0063] Preparation of component B:

[0064] Add 550g of Sovermol 760 and 400g of nitrogen-phosphorus flame retardant into a planetary mixer, vacuum dehydrate at 100°C for 2 hours, and cool down to 60°C. Then add 20g of Evonik A380 hydrophilic silica, 29g of the above adhesion promoter, 1g of bismuth laurate catalyst, and stir for 2h under vacuum to obtain component B with a viscosity of ab...

Embodiment 2

[0085] Preparation of Adhesion Promoter:

[0086] 297g of N-phenyl-γ-aminopropyltriethoxysilane was added to the three-necked flask, stirred and heated to 50°C, 164g of o-tolyl glycidyl ether was added, stirred and reacted at 50°C for 1 hour, then cooled and discharged, An adhesion promoter is obtained.

[0087] Preparation of Component A:

[0088] Add 420g polymethylene polyphenyl isocyanate PM130, 500g aluminum hydroxide, 30g Wacker H16 hydrophobic silica, and 50g diphenyl cresyl phosphate into the planetary mixer, stir and disperse for 1.5h to obtain component A, viscosity About 26Pa·s.

[0089] Preparation of Part B:

[0090] 550g of Sovermol 750 and 380g of nitrogen-phosphorus flame retardant were added to the planetary mixer, dehydrated in vacuum at 100°C for 1.5h, and then cooled to 55°C. Then, 35.5g of Wacker T30 hydrophilic silica, 34g of the above-mentioned adhesion promoter, and 0.5g of bismuth neodecanoate catalyst were added, and the mixture was stirred under va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com