All-water foamed molding slow-rebound bloating foamed cotton of MDI (polymethylene polyphenyl isocyanate) with density of 45kg/m<3> and preparation method

An all-water foaming and molding technology, applied in the field of MDI low-density foaming, which can solve problems such as high steam content, irritation of respiratory mucosa and skin, and bronchial asthma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046]

[0047]

example 2

[0049]

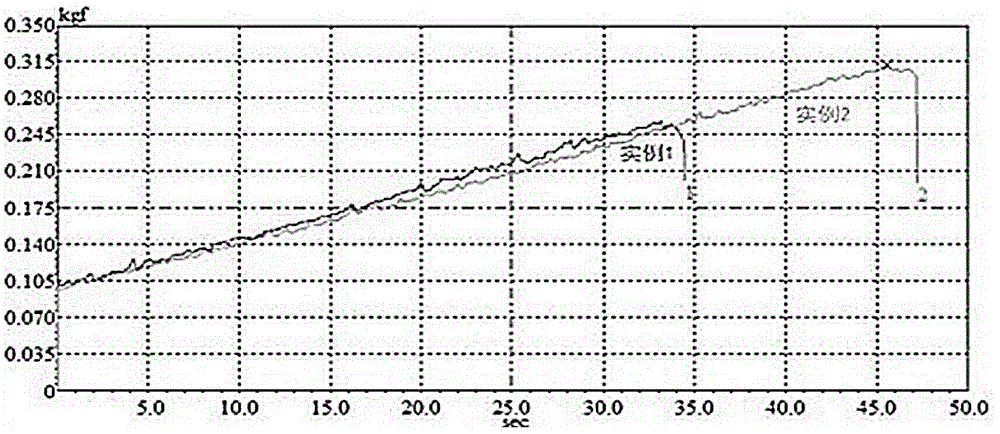

[0050] The tensile test report of the present invention is as follows, and the corresponding tensile test diagram is shown in figure 1 .

[0051] test number

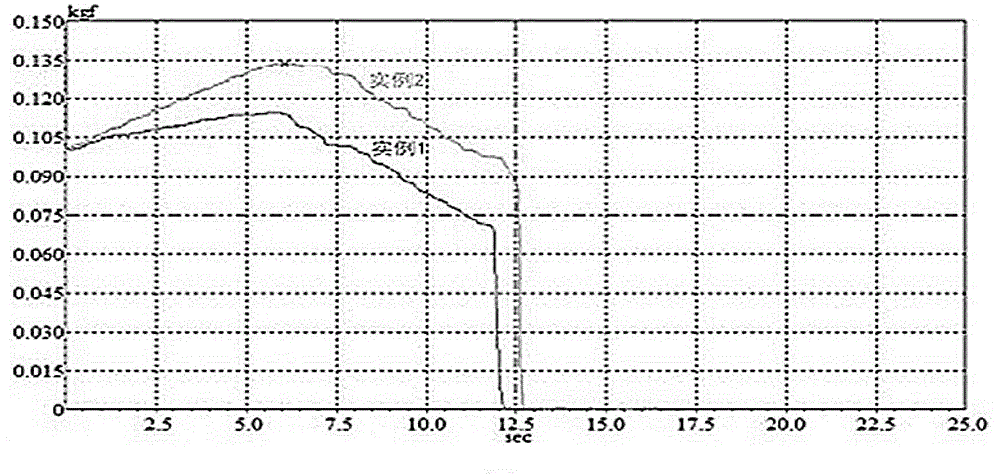

[0052] The tear test report of the present invention is as follows, and the corresponding tear test chart is shown in figure 2 .

[0053] test number

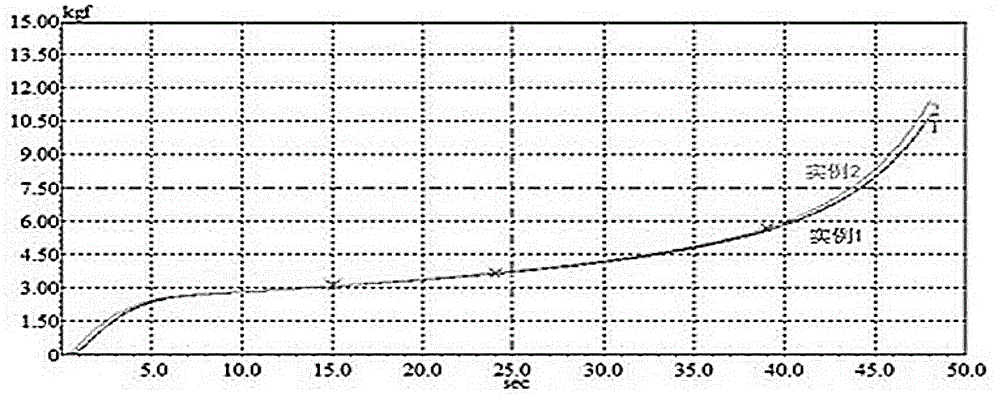

[0054] The compression test report of the present invention is as follows, and the corresponding compression test diagram is shown in figure 2 .

[0055] test number

[0056] According to the test data, except for the slight problem in the tensile strength of the final product of the present invention, all the other physical properties have reached or exceeded the national "GB / T24451-2009" standard for slow rebound testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com