Automobile roof polyurethane composition

A technology for automobile roof and composite materials, which is applied in the field of polyurethane automobile roof composite materials, and can solve problems such as high aldehyde content, high VOC value, and strong odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

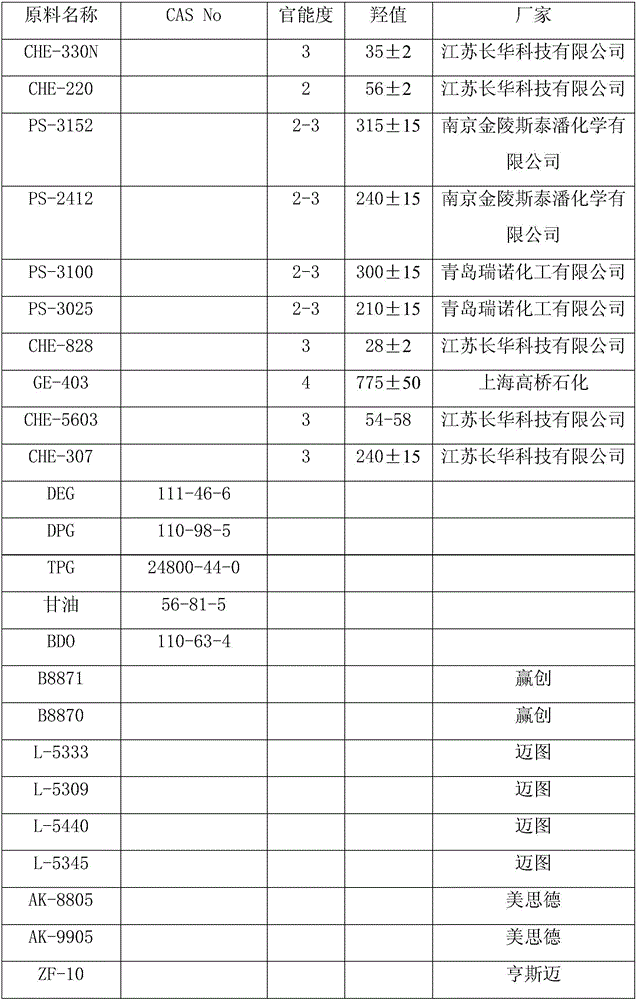

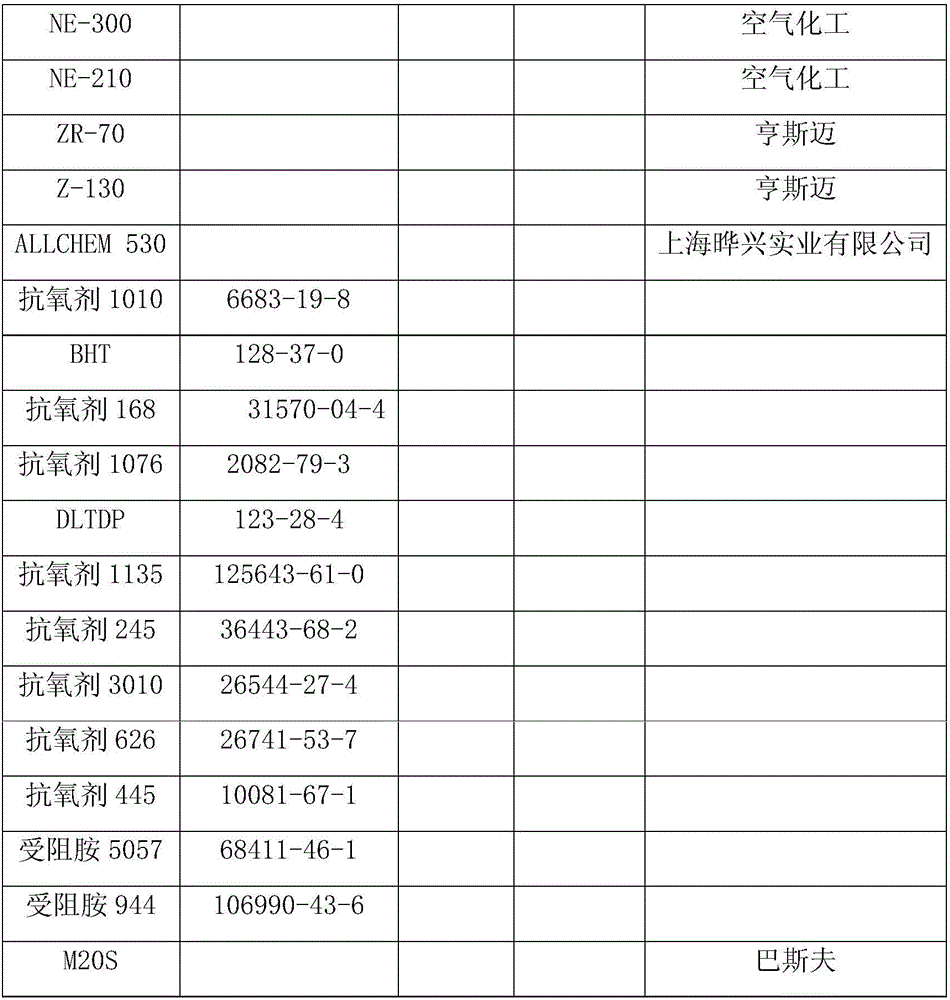

Method used

Image

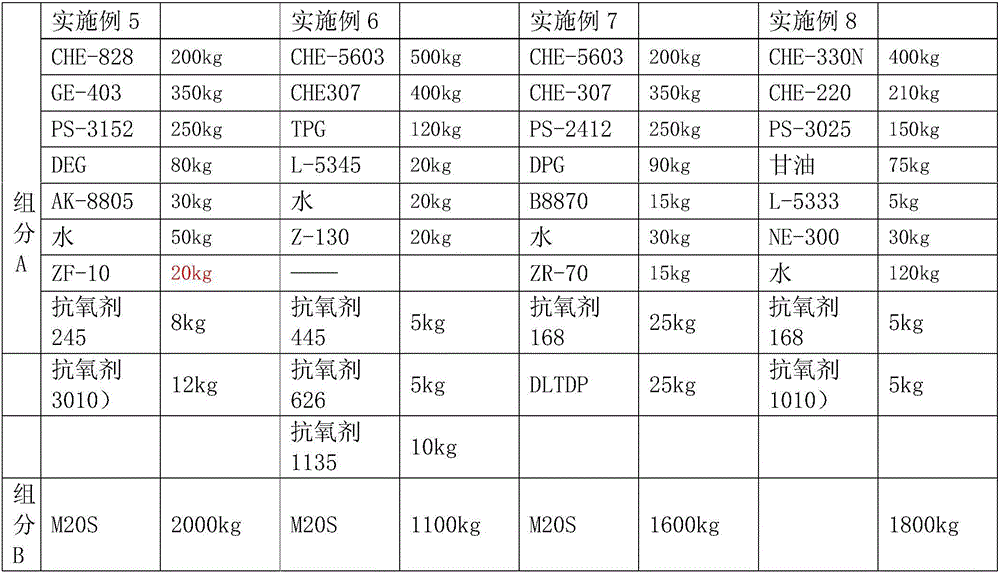

Examples

Embodiment 1

[0020] 1. Preparation of component A: 1000kg: Weigh polyether polyol Ⅰ: CHE-330N (Jiangsu Changhua) 400kg, polyether polyol Ⅱ: CHE-220 (Jiangsu Changhua) 300kg, polyester polyol: PS -3152 (Nanjing Stepan) 200kg, chain extender: DEG45kg, foam stabilizer: B8871 (Evonik) 15kg, catalyst: ZF-10 (huntsman) 5kg, water: 30kg, compound antioxidant: antioxidant 1010: 2kg, antioxidant 168: 3kg;

[0021] 2. Add the weighed polyether polyol Ⅰ, polyether polyol Ⅱ, polyester polyol, chain extender, foam stabilizer, catalyst, water, and antioxidant into the reaction kettle in sequence, and stir at room temperature 2 hours, mix well;

[0022] 3. Weigh component B as polymethyl polyphenyl polyisocyanate M20S: 1200kg;

[0023] 4. Set the box size according to the required size before foaming, and control the temperature of component A and component B to 16-24 degrees;

[0024] 5. Mix component A and component B according to the weight ratio of 1:1.2, mix them evenly through a foaming machine,...

Embodiment 2

[0026] 1. Preparation of component A: 1000kg: Weigh polyether polyol Ⅰ: CHE-828 (Jiangsu Changhua Technology Co., Ltd.) 350kg, polyether polyol Ⅱ: GE-403 (Gaoqiao Petrochemical) 200kg, polyester polyol Alcohol: PS3152 (Nanjing Stepan) 200kg, chain extender: glycerin 140kg, foam stabilizer: AK-8805 (Mesid) 15kg, catalyst: NE-300 (Air Chemicals) 5kg, water: 50kg, compound anti Oxygen: Antioxidant 168: 1kg, BHT: 1kg, Antioxidant 445: 3kg;

[0027] 2. Add the weighed polyether polyol Ⅰ, polyether polyol Ⅱ, polyester polyol, chain extender, foam stabilizer, catalyst, water, and antioxidant into the reaction kettle in sequence, and stir at room temperature 2 hours, mix well;

[0028] 3. Weigh component B as polymethyl polyphenyl polyisocyanate M20S: 1500kg;

[0029] 4. Set the box size according to the required size before foaming, and control the temperature of component A and component B to 16-24 degrees;

[0030] 5. Mix component A and component B according to the weight ratio...

Embodiment 3

[0032] 1. Preparation of component A: 1000kg: Weigh polyether polyol Ⅰ: CHE-5603 (Jiangsu Changhua) 300kg, polyether polyol Ⅱ: CHE-307 (Jiangsu Changhua) 390kg, polyester polyol: PS2412 (Nanjing Stepan) 200kg, chain extender: BDO40kg, foam stabilizer: B8871 (Evonik) 15kg, catalyst: ZF-10 (huntsman) 5kg, water: 45kg, compound antioxidant: antioxidant 3010: 2kg, antioxidant 1135:3kg;

[0033] 2. Add the weighed polyether polyol Ⅰ, polyether polyol Ⅱ, polyester polyol, chain extender, foam stabilizer, catalyst, water, and antioxidant into the reaction kettle in sequence, and stir at room temperature 2 hours, mix well;

[0034] 3. Weigh component B as polymethyl polyphenyl polyisocyanate M20S: 1600kg;

[0035] 4. Set the box size according to the required size before foaming, and control the temperature of component A and component B to 16-24 degrees;

[0036] 5. Mix component A and component B according to the weight ratio of 1:1.6, mix them evenly through a foaming machine, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com