High-strength and high-toughness polyurethane material, as well as preparation method and use thereof

A polyurethane material and high toughness technology, applied in the field of polyurethane polymer materials, can solve problems such as high strength, complicated operation steps, and complicated processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

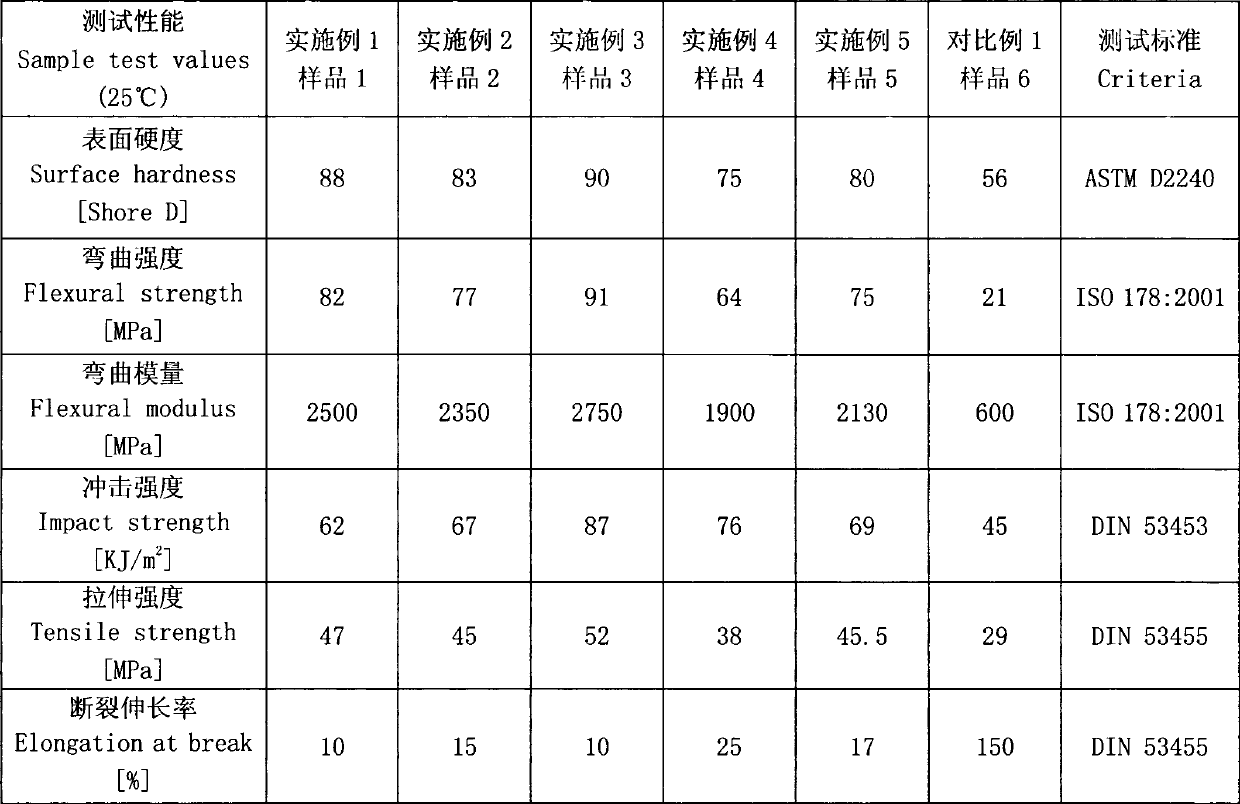

Examples

Embodiment 1

[0048]In the MDI-100 (Yantai Wanhua, NCO content is 33.5wt%, with MDI-100 weight) preheated at 60 ℃, add the TDiol-400 (weight average molecular weight 400) through dehydration that is preheated at 60 ℃ Difunctional polyoxyethylene-polyoxypropylene copolyether polyol, Tianjin Sanpei), the weight ratio of MDI-100 and TDiol-400 is 5.76:1, react at 75-80°C for 1.5-2.0 hours, defoam and set aside , The NCO content of the obtained polyurethane prepolymer 1 is 25.5 wt%, based on the weight of the polyurethane prepolymer 1.

[0049] Component A is composed of 27wt% polyurethane prepolymer 1 and 25wt% PM-200 (Yantai Wanhua, with an NCO content of 32.0wt%, based on the weight of PM-200).

[0050] Component B is composed of 10wt% small molecule chain extender, 35wt% N 307 (trifunctional polyoxyethylene-polyoxypropylene copolyether polyol with a weight average molecular weight of 700, Nanjing Zhongshan Chemical Industry Co., Ltd.), in which small molecule chain extender The agent is com...

Embodiment 2

[0054] In TDI-80 preheated at 60°C (Cangzhou Dahua, NCO content is 48.2wt%, based on TDI-80 weight), add Poly THF 1000 (weight average molecular weight 1000 Difunctional polytetrahydrofuran polyol (BASF), the weight ratio of TDI-80 to Poly THF 1000 is 1.02:1, reacted at 75-80°C for 1.5-2.0 hours, defoamed for use, and the obtained polyurethane prepolymer 2 The NCO content of is 20.2wt%, based on the weight of polyurethane prepolymer 2.

[0055] Component A is composed of 5wt% polyurethane prepolymer 2 and 55wt% TDI trimer (Yantai Wanhua, NCO content is 8.0wt%, based on the weight of TDI trimer).

[0056] Component B consists of 2wt% small molecule chain extender, 30wt% Poly THF 1000 (difunctional polytetrahydrofuran polyol with weight average molecular weight 1000, BASF), 5wt% D-2000 (difunctional polytetrahydrofuran polyol with weight average molecular weight 2000 amino-terminated polyether, Huntsman), wherein the small molecule chain extender is composed of 3,3'-dichloro-4,...

Embodiment 3

[0061] Dicyclohexylmethane diisocyanate (H 12 MDI, NCO content is 32.0wt%, as H 12 MDI weight meter, Yantai Wanhua), add TDiol-400 (difunctional polyoxyethylene-polyoxypropylene copolyether polyol with a weight average molecular weight of 400, Tianjin Sanpei Chemical Co., Ltd.) that has been dehydrated and preheated at 60 ° C. h 12 The weight ratio of MDI to TDiol-400 is 20:1, react at 75-80°C for 1.5-2.5 hours, defoam and stand-by, the NCO content of the obtained polyurethane prepolymer 3 is 29.5wt%. 3 weights.

[0062] Component A consists of 14wt% polyurethane prepolymer 3, 29wt% PM-200 (Yantai Wanhua, NCO content is 32.0wt%, with PM-200 weight), 5wt% HDI trimer (Yantai Wanhua, NCO content is 21.8wt%, based on HDI trimer weight).

[0063] Component B is composed of 7wt% small molecule chain extender, 42wt% TMN 700 (trifunctional polyoxyethylene-polyoxypropylene copolyether polyol with a weight average molecular weight of 700, Tianjin Sanpei Chemical Co., Ltd.), in which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com