Polyurethane heat insulation foaming material and preparation method thereof

A technology of thermal insulation and foaming materials, applied in the field of polyurethane materials, can solve the problems that the foaming agent is not an environmentally friendly foaming agent, loses thermal insulation performance, does not specify the type of foaming agent, thermal insulation performance, mechanical properties, and flame retardant properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] Step 1: Dry the polyether polyol, isocyanate and expanded perlite at 40°C for 8 hours, and place at room temperature for use.

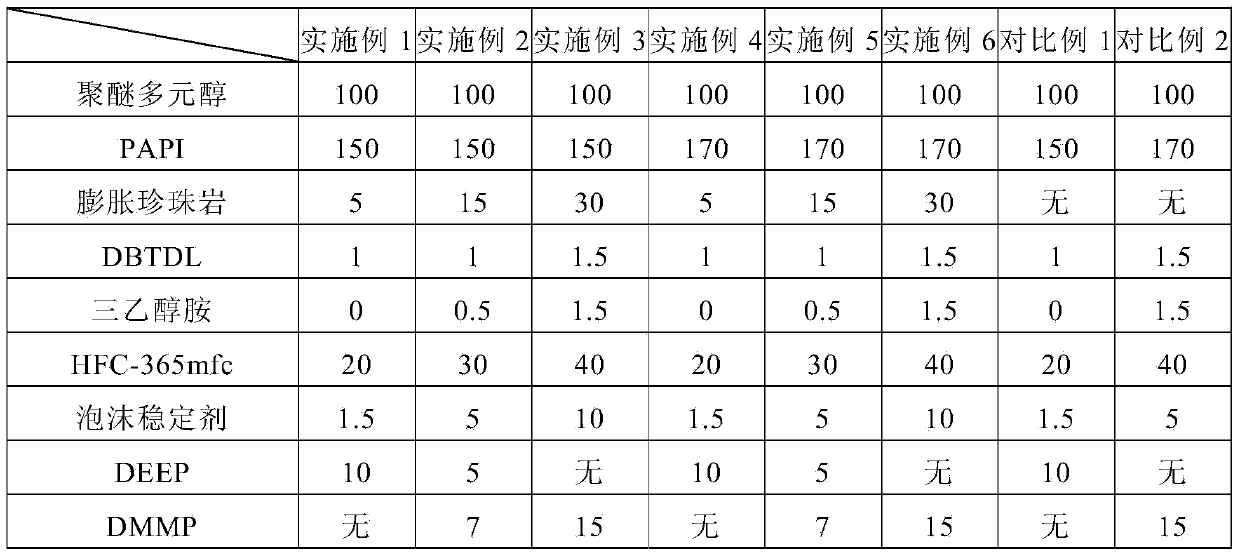

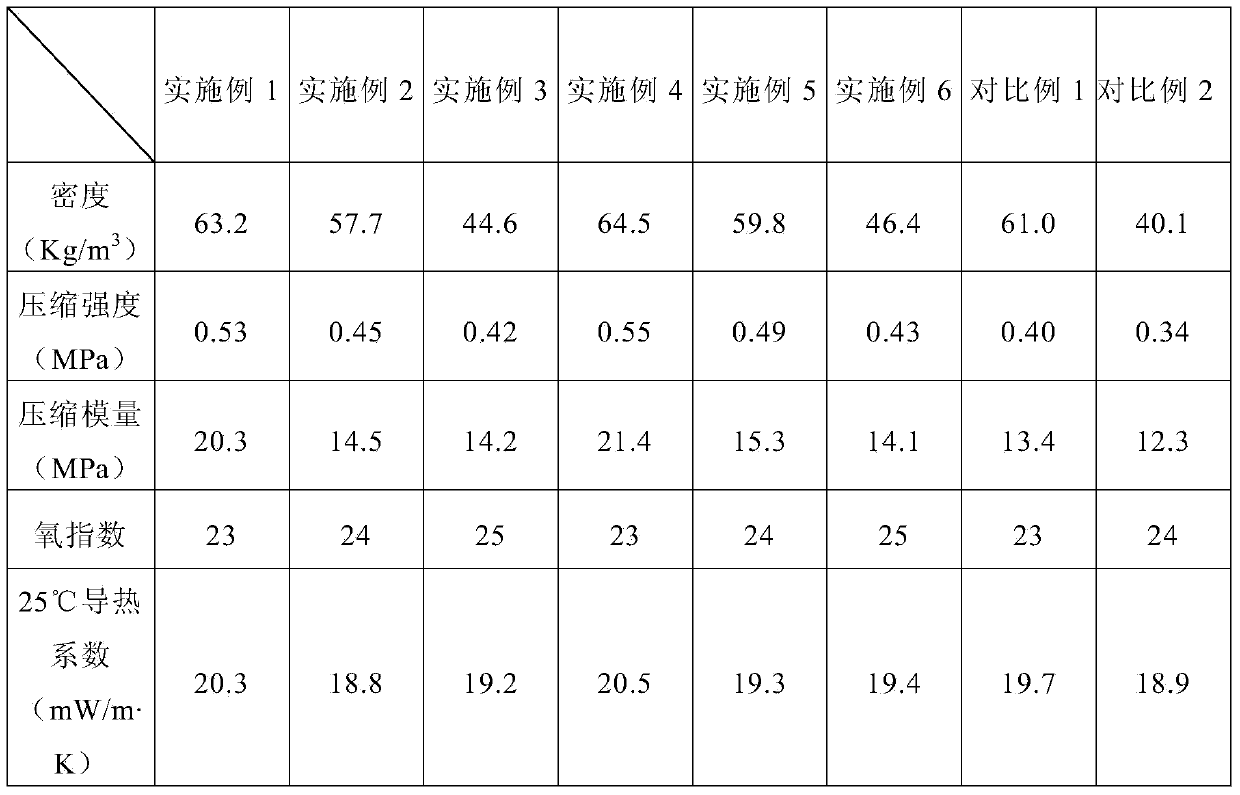

[0041]The second step: according to the formula of Example 1-6 in Table 1, add the expanded perlite with an average particle size of 0.06 to 0.8 mm into the polyether polyol after weighing according to the formula, and add flame retardant and catalyst according to the formula , Foam stabilizer, stir fully with a mechanical stirring device, mix evenly, then add the physical foaming agent HFC-365mfc, use a mechanical stirring device to fully stir, mix evenly; quickly add isocyanate to the mixed components, and fully stir at the same time, 30 After ~50 seconds, it is poured into a mold and foamed freely to obtain a pouring mold blank. React with the mold at 40°C for 40 minutes, remove the mold, and then put it into an oven for aging at 50-100°C for more than 6 hours to obtain the product.

[0042] With the two steps of above-mentioned embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com