Method for treating coal gasification wastewater by single tower alkali injection and pressurization steam stripping

A technology for coal gasification sewage and alkali injection, which is applied in the fields of degassed water/sewage treatment, ammonia preparation/separation, etc., can solve the problems of affecting biochemical treatment, excessive fixed ammonium content, and ignoring fixed ammonium, etc., to meet biochemical treatment requirements. requirements, reduce processing load, and reduce equipment investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

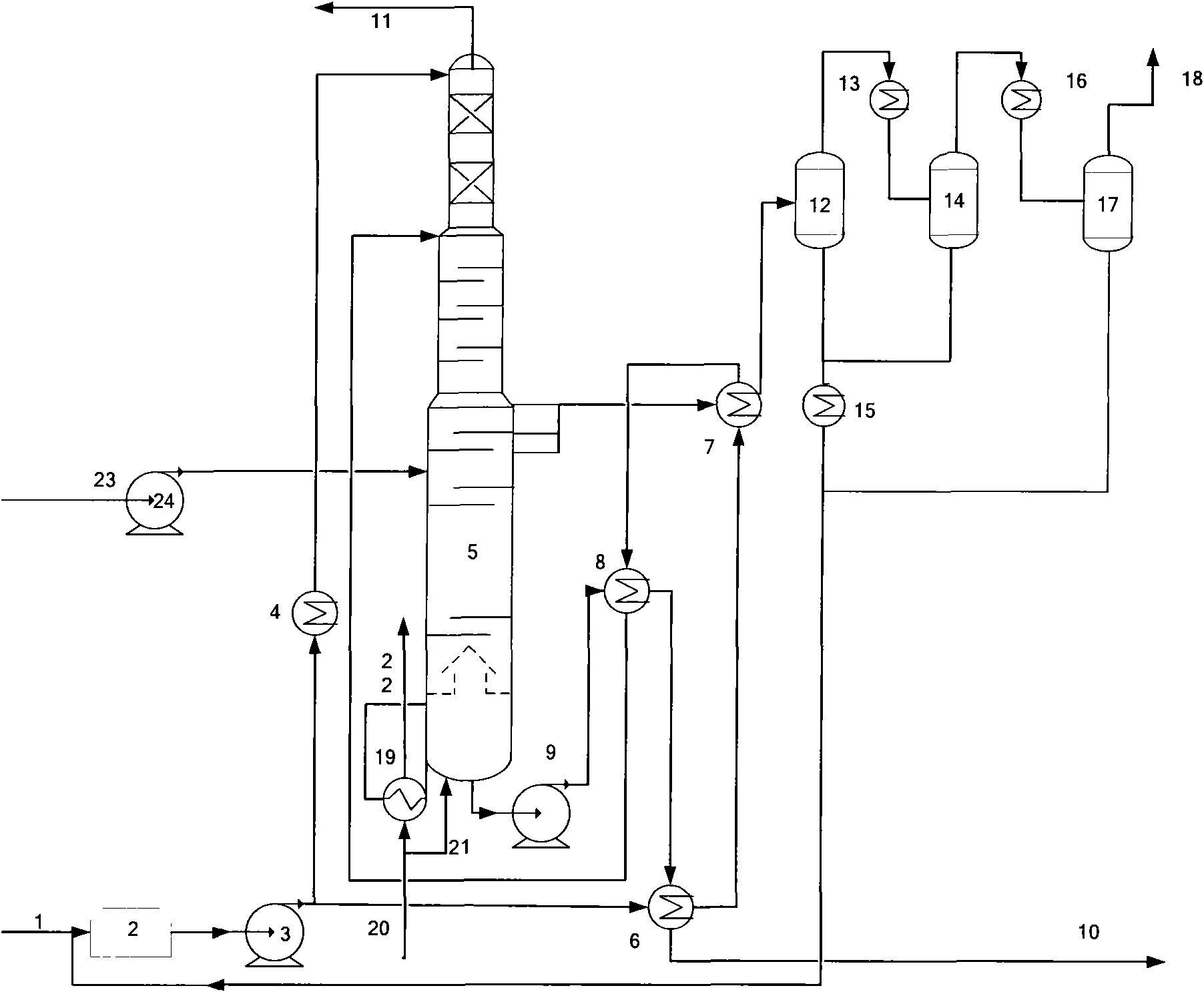

[0018] Coal gasification raw sewage 1 containing carbon dioxide, hydrogen sulfide, ammonia and phenol, the flow rate is 89.1t / hr, the total ammonia is 5104mg / L (of which the fixed ammonium is 870mg / L), the carbon dioxide concentration is 2309mg / L, and the hydrogen sulfide is 81mg / L, the pH value is 10.5, the total phenol content is 6500mg / L, enters the raw material water tank 2, pressurizes by the raw material water pump 3, and divides into two feeds according to the weight ratio of cold raw material water and hot raw material water as 1:4 Enter the stripper 5, the cold feed water feed passes through the cold feed water heat exchanger 4 and then enters the upper part of the packing section at the top of the stripper to keep the temperature at the top of the tower at 46.5°C; another stream of hot feed water passes through Hot feed primary heat exchanger 6, hot feed secondary heat exchanger (also a primary condensing cooler) 7, hot feed tertiary heat exchanger 8, heat exchange w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com