Precise electrotyping shaping technology and device by cathode motion prinding method

A forming process and electroforming technology, applied in electroforming, electrolytic process and other directions, can solve the problem of inappropriate electroforming forming, and achieve the effects of improving the quality of the casting layer, increasing the speed of electroforming, and reducing the thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

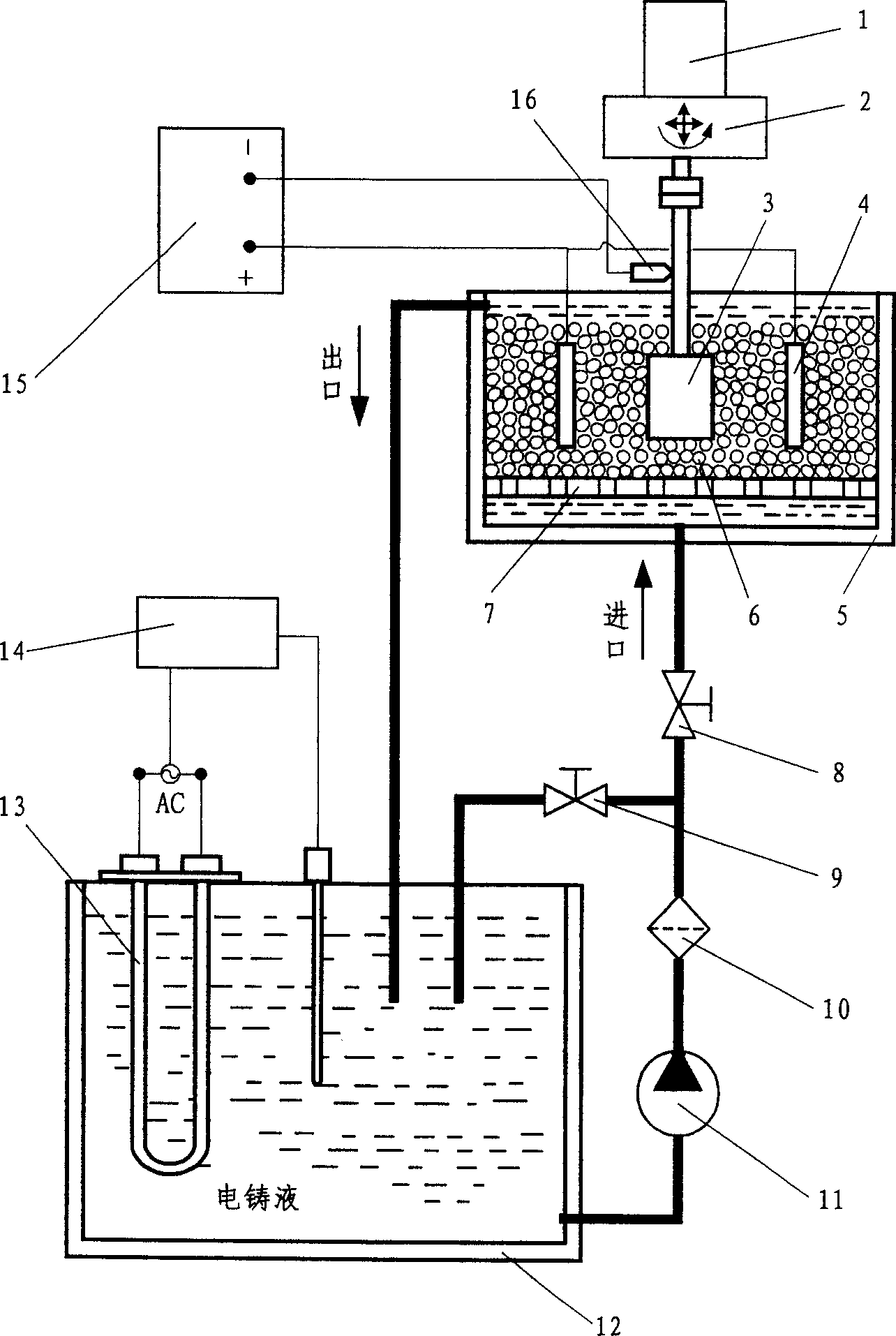

[0015] Implementation of the present invention - "cathode motion friction precision electroforming process" device, such as figure 1 As shown, the device includes a motor (1), an electroforming tank (5), an isolation plate (7), a liquid storage tank (12), a magnetic pump (11), a filter (10), a ball valve (8), an overflow Valve (9), temperature controller (14), heater (13), power supply (15), conductive device (16). It is characterized in that the electroforming process device, including the electroforming mandrel (3) through the transmission device (2), realizes the corresponding movement mode for different part shapes; the hard particles (6) are stacked on the top of the isolation plate (7) The surroundings of the cathode (3) and the anode (4) are completely immersed in the electroforming solution.

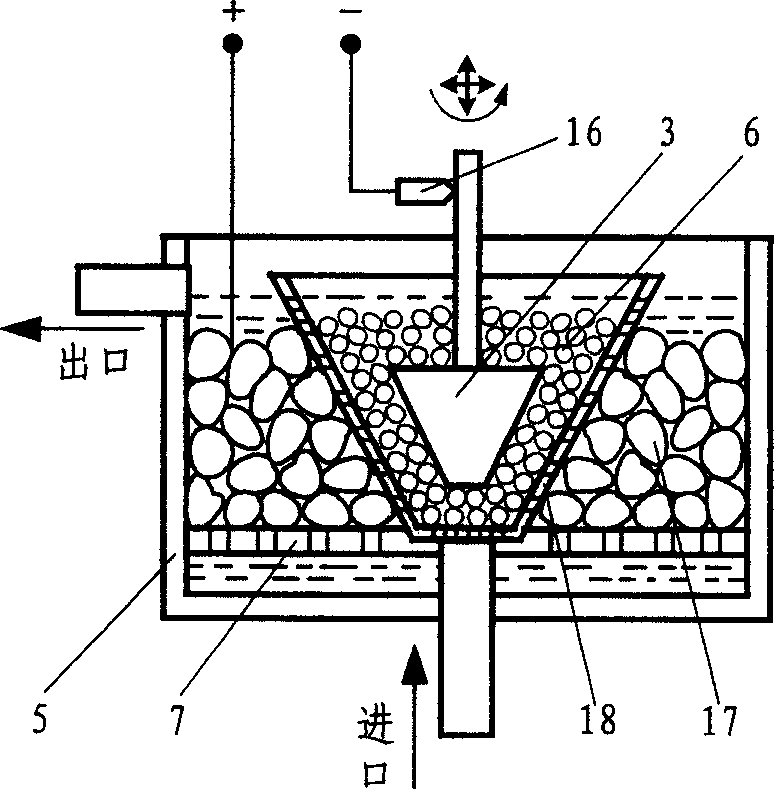

[0016] figure 2 Shown is a schematic diagram of the device structure of the granular anode electroforming process. The hard particles (6) are stacked in the like-shaped anode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com