Over-ground slurry settling, filtering and separating apparatus capable of obtaining clear water

A filtration separation and slurry technology, applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve the problems of high power consumption, inability to be directly applied, and cleaning of the upper slurry water, and achieve the effect of saving transportation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

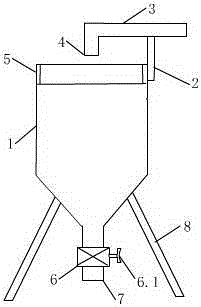

[0012] according to figure 1 As shown, a settling tube 1 with a conical upper portion with an opening is fixed on one side of the upper part of the settling tube 1, on which a slurry tube 3 is fixed, and the slurry tube is arranged at 90 degrees downward. There is a slurry port 4, a slag discharge pipe 7 is connected to the lower conical end of the settling cylinder, a slag discharge valve 6 with a valve handle 6.1 is installed on the slag discharge pipe, and a support frame 8 is provided on the lower conical part of the settling cylinder .

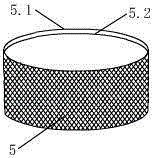

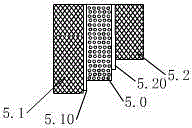

[0013] The filter ring 5 is installed on the upper edge of the settling cylinder, and the filter ring is provided with an outer net 5.1 and an inner net 5.2, an outer filter cloth 5.10 is arranged on the inner side of the outer net, and an inner filter cloth is arranged outside the inner net 5.20, a filter layer 5.0 is installed between the inner filter cloth and the outer filter cloth.

[0014] The outer net and the inner net are metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com