Construction method for pipe gallery to down-pass river channel

A construction method and pipe gallery technology, applied in artificial islands, water conservancy projects, soil protection, etc., can solve the problems of poor applicability of the diversion method, high cost of the pipe jacking construction method, and damage to the environment, so as to improve the waterproof effect and effectively Conducive to urban environmental protection and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

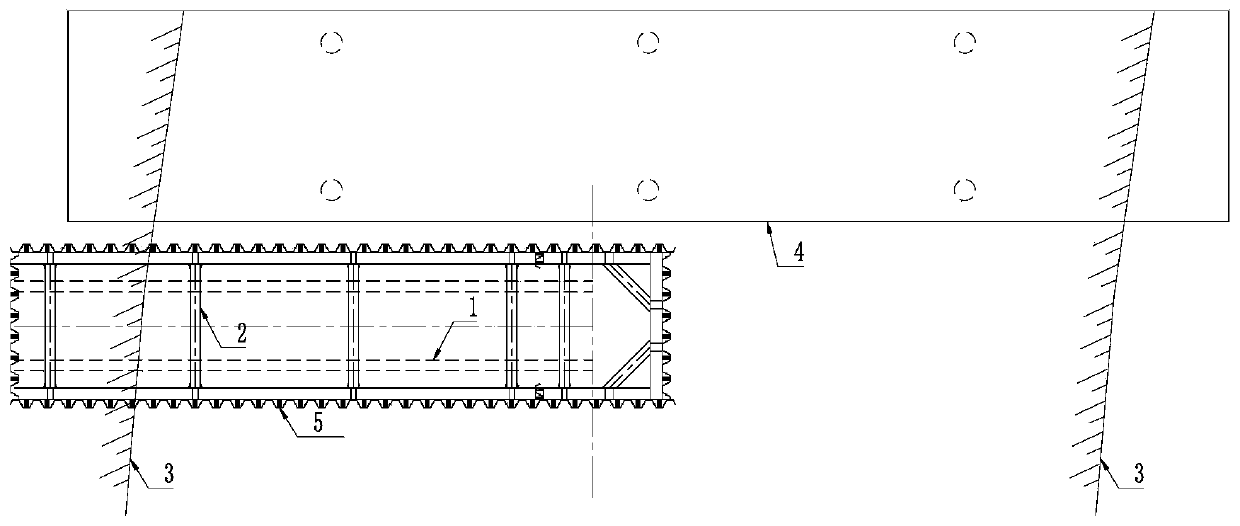

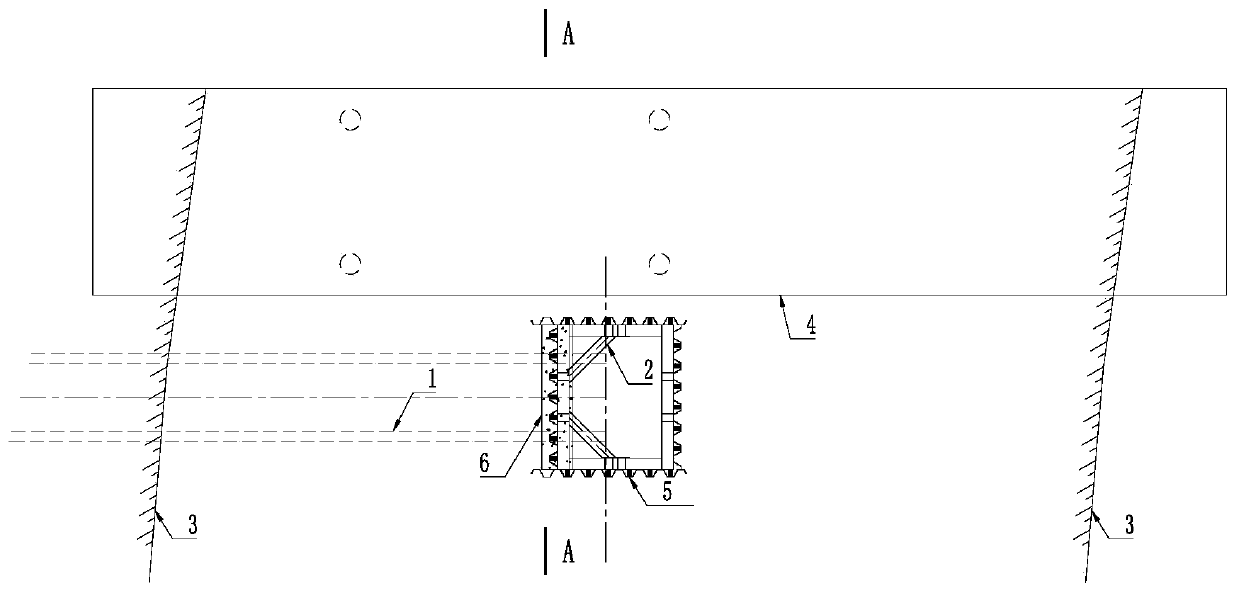

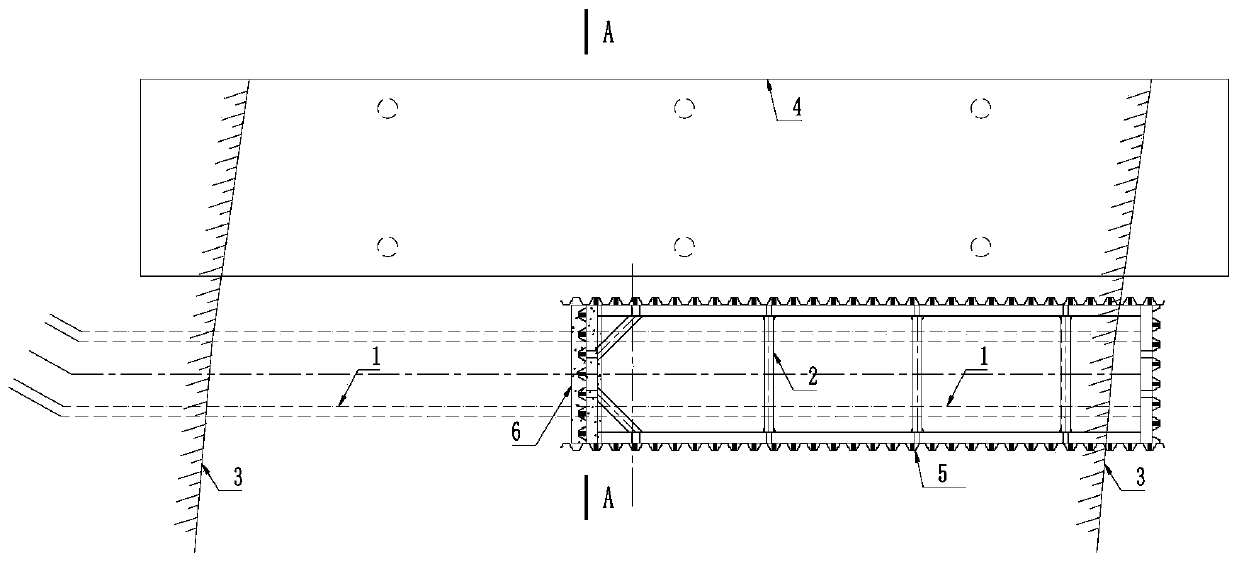

[0032] figure 1 It is a construction schematic diagram of the construction methods S1 and S2 of the pipe gallery under the river channel in the embodiment of the present invention. see figure 1 As shown, the embodiment of the present invention provides a construction method for a pipe gallery to cross a river, including the following steps:

[0033] First, a trestle 4 is erected next to the line of the pipe gallery 1 to be installed. The trestle 4 can be used as a construction platform and as a temporary river crossing channel. Construction materials such as steel sheet piles and concrete can be transported to the construction area in Hanoi through the trestle 4 .

[0034] S1: Insert steel sheet piles from one bank of the river to the opposite bank to form a cofferdam until the end of the cofferdam reaches the set position.

[0035] Speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com