Emission-reduction gasoline and diesel additive and preparation method thereof

A technology of gasoline, diesel and additives, applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve problems such as single function and lack of lubrication and maintenance functions, and achieve the effects of improving efficiency, solving start-up difficulties, and eliminating carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the weight ratio of flake graphene, tetraneedle zinc oxide and absolute ethanol as 1:1:20, add flake graphene into absolute ethanol, after ultrasonic dispersion treatment for 3 hours, then add tetraacicular zinc oxide Zinc oxide, continue ultrasonic dispersion treatment for 3h, after centrifugation, dry at 70°C for 10h to obtain graphene / zinc oxide powder; weigh the following raw materials by weight percentage: graphene / zinc oxide blend powder 5 %, coconut oil 16%, polyisobutylamine 8%, ferrocene 0.2%, oleic acid carboxylate 2.6%, demulsifier 0.3%, de-aromatized hydrocarbon solvent oil balance; graphene / zinc oxide blend powder, di Add ferrocene, oleic acid carboxylate, polyisobutylene amine, and demulsifier into the mixing reaction kettle, mix and stir for 30 minutes, then add coconut oil and dearomatized solvent oil into the mixing reaction kettle in turn, and stir for 1.5 hours to obtain emission-reducing steam Diesel additives.

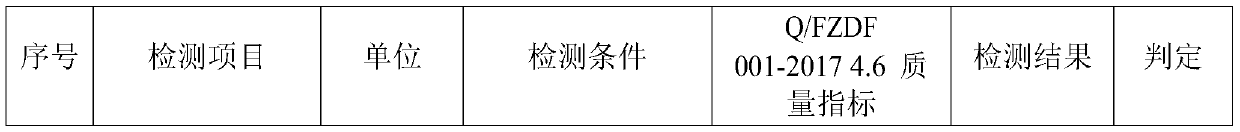

[0023] The performance ...

Embodiment 2

[0027] According to the weight ratio of flake graphene, tetrapod zinc oxide and absolute ethanol as 2:1:20, add flake graphene into absolute ethanol, after ultrasonic dispersion treatment for 3h, then add tetrapod Zinc oxide, continue ultrasonic dispersion treatment for 3h, after centrifugation, dry at 70°C for 10h to obtain graphene / zinc oxide powder; weigh the following raw materials by weight percentage: graphene / zinc oxide blend powder 5 %, coconut oil 16%, polyisobutylamine 8%, ferrocene 0.2%, oleic acid carboxylate 2.6%, demulsifier 0.3%, de-aromatized hydrocarbon solvent oil balance; graphene / zinc oxide blend powder, di Add ferrocene, oleic acid carboxylate, polyisobutylene amine, and demulsifier into the mixing reaction kettle, mix and stir for 30 minutes, then add coconut oil and dearomatized solvent oil into the mixing reaction kettle in turn, and stir for 1.5 hours to obtain emission-reducing steam Diesel additives.

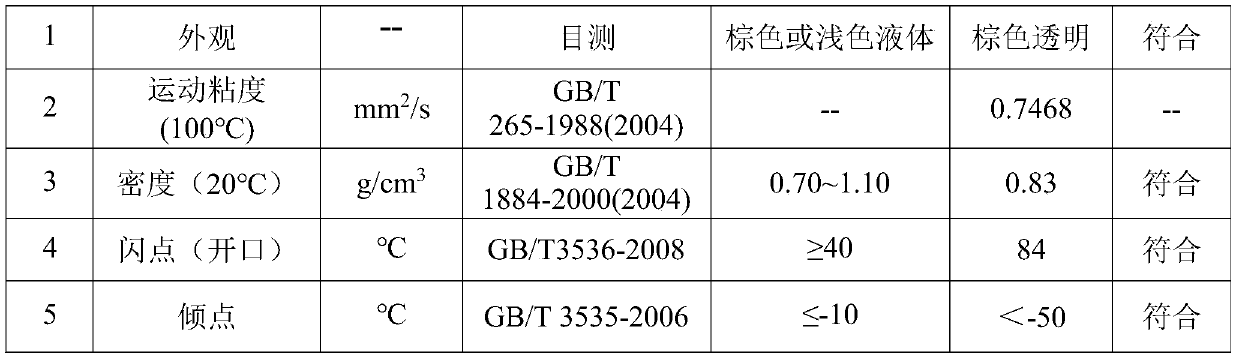

[0028] The performance test result of above-men...

Embodiment 3

[0031] According to the weight ratio of flake graphene, tetrapod zinc oxide and absolute ethanol as 3:1:20, add flake graphene into absolute ethanol, after ultrasonic dispersion treatment for 3h, add tetrapod shape Zinc oxide, continue ultrasonic dispersion treatment for 3h, after centrifugation, dry at 70°C for 10h to obtain graphene / zinc oxide powder; weigh the following raw materials by weight percentage: graphene / zinc oxide blend powder 5 %, coconut oil 16%, polyisobutylamine 8%, ferrocene 0.2%, oleic acid carboxylate 2.6%, demulsifier 0.3%, de-aromatized hydrocarbon solvent oil balance; graphene / zinc oxide blend powder, di Add ferrocene, oleic acid carboxylate, polyisobutylene amine, and demulsifier into the mixing reaction kettle, mix and stir for 30 minutes, then add coconut oil and dearomatized solvent oil into the mixing reaction kettle in turn, and stir for 1.5 hours to obtain emission-reducing steam Diesel additives.

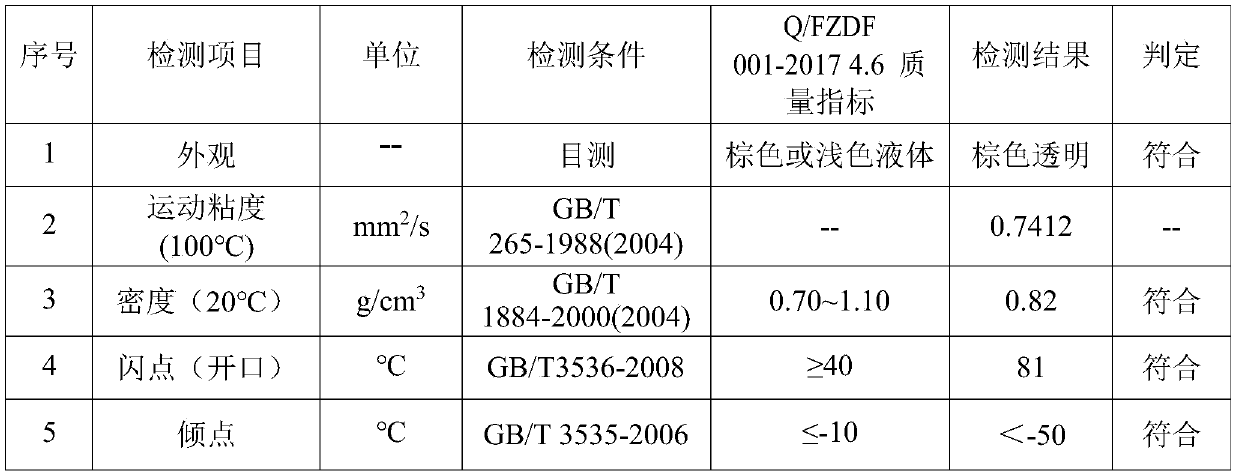

[0032] The performance test result of above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com