Horizontal rotary compressor

A rotary compressor and rotary compression technology, which is applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve problems such as the inability to smoothly achieve oil suction, and achieve the effect of eliminating obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

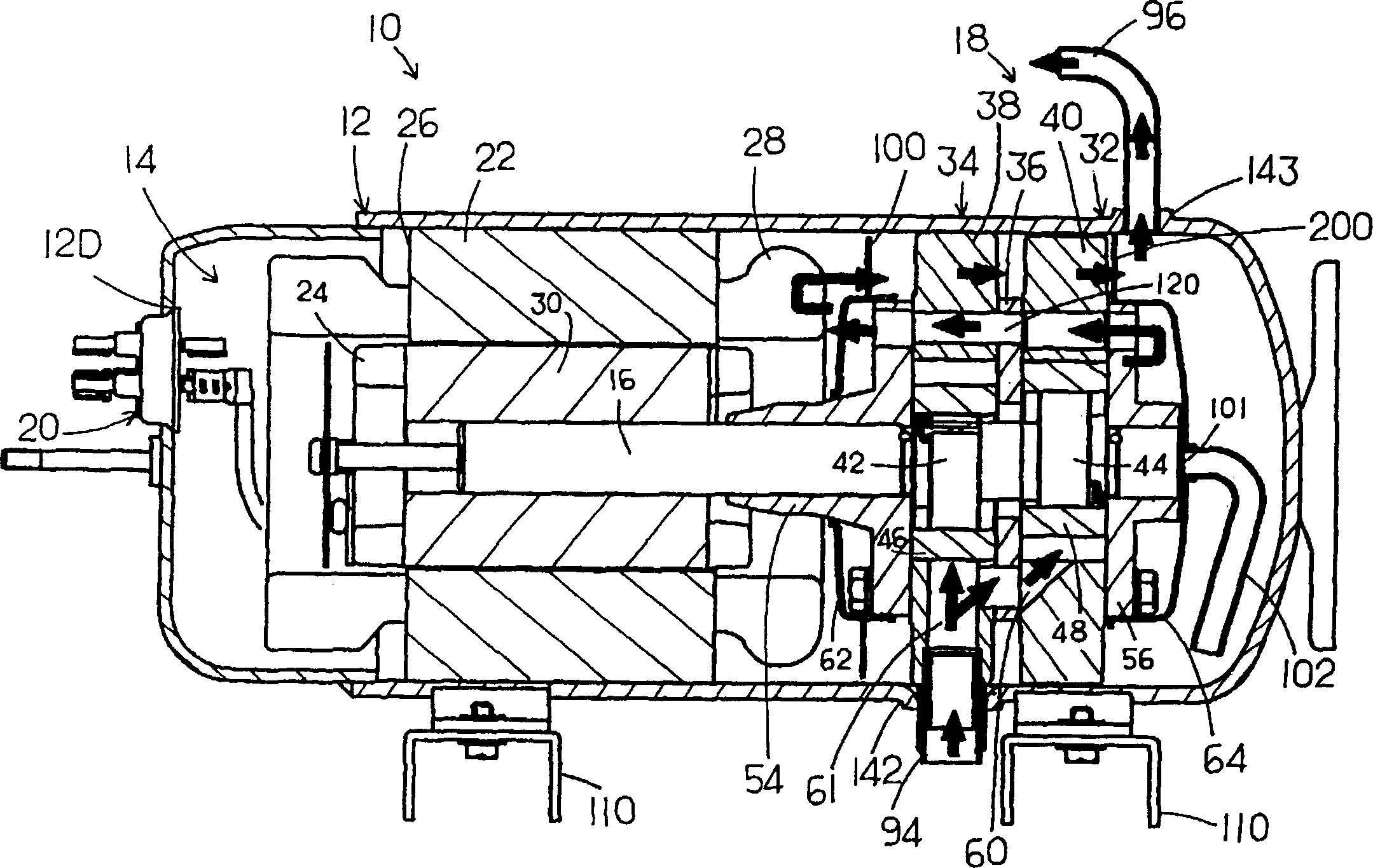

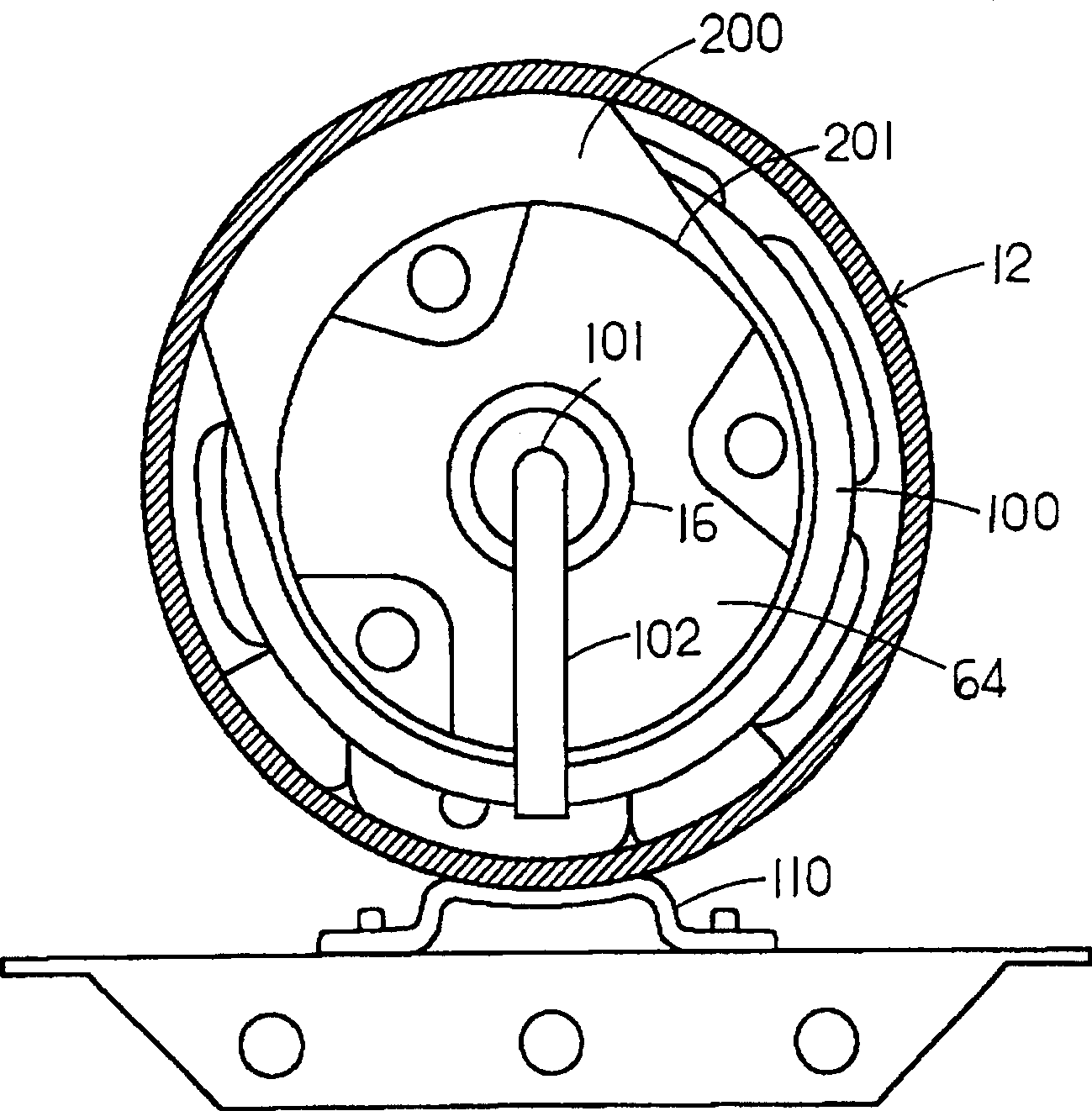

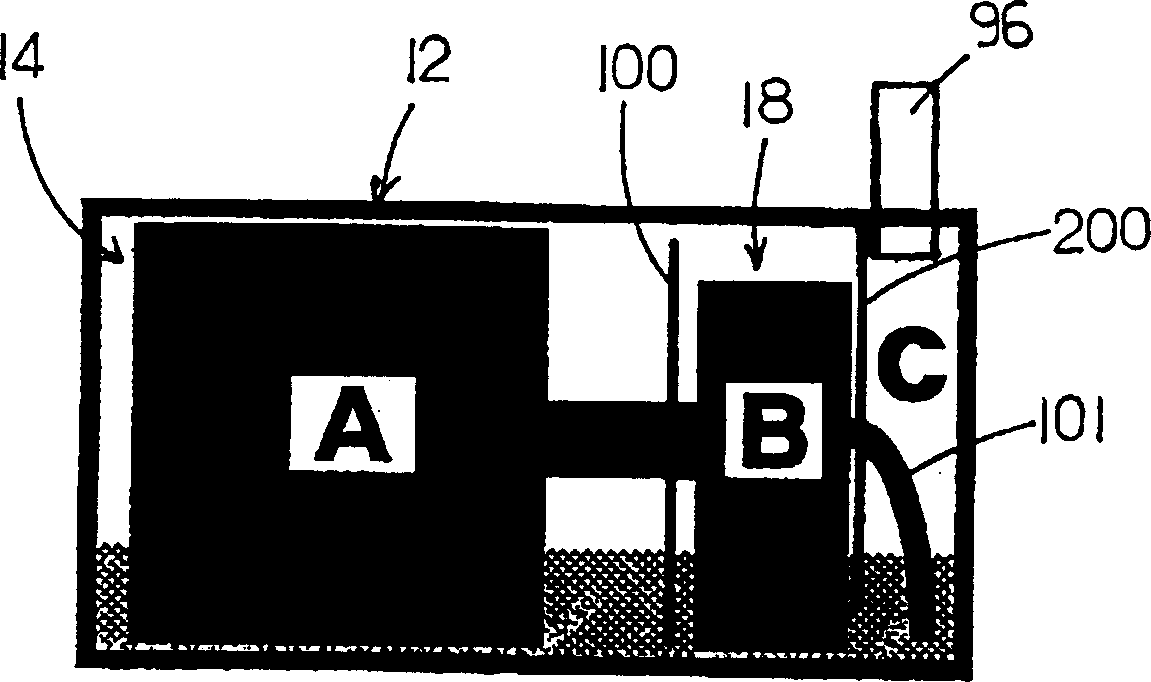

[0017] Embodiments of the present invention will be specifically described below according to the accompanying drawings. figure 1 It is a longitudinally cut side view of an internal high-pressure type horizontal rotary compressor 10 having first and second rotary compression members as an embodiment of the horizontal rotary compressor of the present invention, figure 2 for figure 1 A longitudinally sectioned side view of the rotary compressor 10.

[0018] In each figure, the horizontal rotary compressor 10 of the embodiment is an internal high-pressure type horizontal rotary compressor, which includes a horizontally long cylindrical airtight container 12, and both ends of the airtight container 12 are airtight. The bottom of the airtight container 12 forms an oil storage portion. Inside the airtight container 12, the electric component 14 and the rotary compression mechanism part 18 are accommodated by the first rotary compression component 32 and the second rotary compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com