Locking device for dual capacity compressor

A technology of latch device and compressor, which is applied to parts of pumping devices for elastic fluids, liquid variable capacity machines, mechanical equipment, etc., can solve problems such as functional impact, length of connecting rods, etc., and achieve improvement Effects of function, length reduction, and durability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

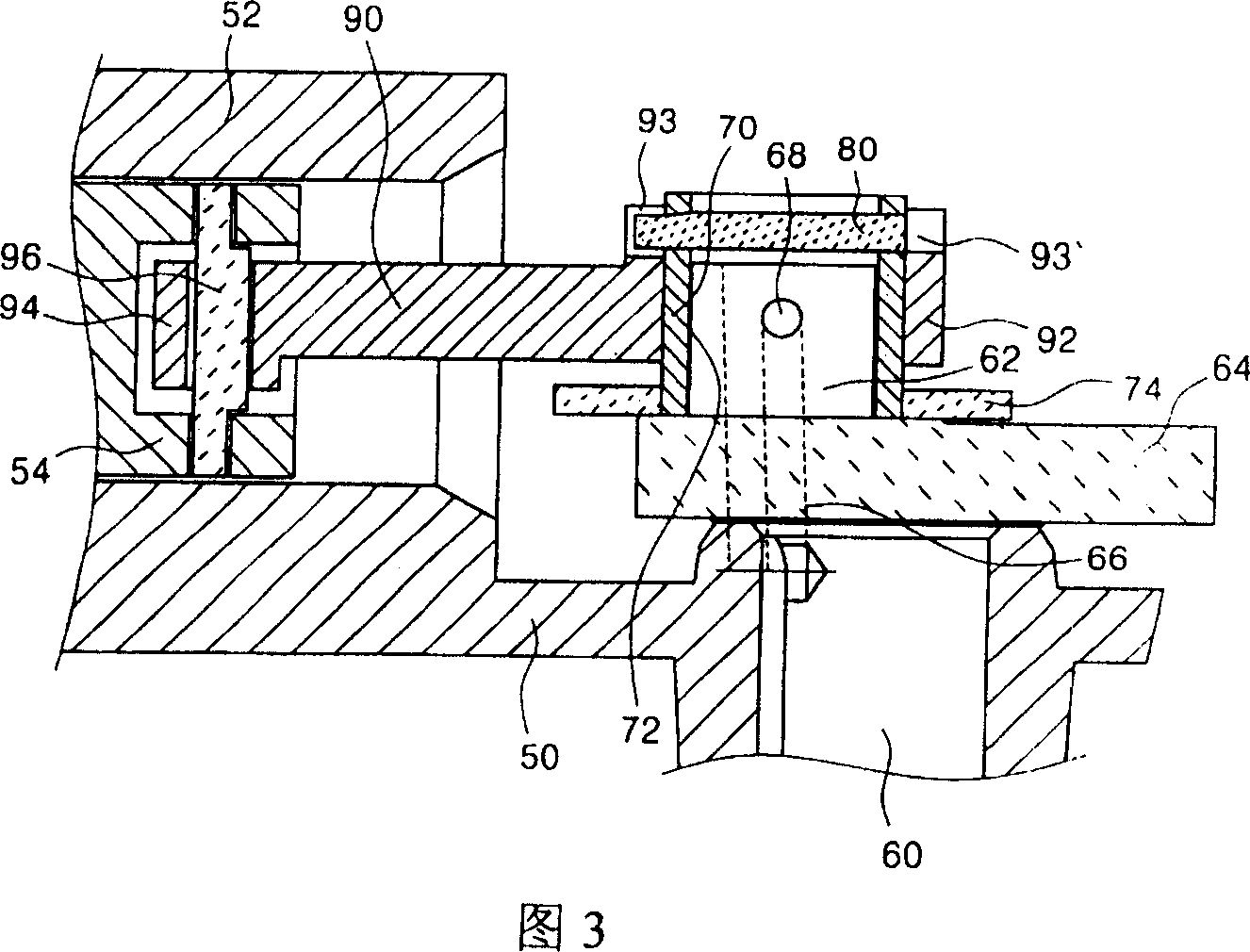

[0030] In order to further understand the content, characteristics and effects of the present invention, the following examples are given as examples and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0031] Fig. 3 is a cross-sectional view of the structure of the latch device of the double capacity compressor designed according to the present invention. As shown in the figure, a cylinder (52) is arranged on one side of the frame (50), and a piston (54) is arranged inside the cylinder (52), and the linear reciprocating motion of the piston is considered during setting. The frame (50) is located inside the airtight container of the compressor, and there are various other parts constituting the compressor inside.

[0032] The crankshaft (60) runs through the upper and lower sides of the frame (50). The crankshaft (60) is driven by the motor to rotate, and its upper end is provided with an eccentric portion (62). The eccentric portion (62)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com