Lubricating structure for slewing bearing for engineering machinery

A technology of slewing bearing and construction machinery, which is used in mechanical equipment, rotating bearings, bearings, etc. to ensure normal operation and uniform oil supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

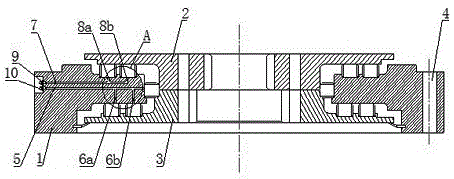

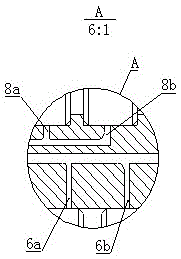

[0010] Such as figure 1 , 2 As shown, it includes seat ring 1, upper shaft ring 2, lower shaft ring 3 and cylindrical rolling elements.

[0011] The seat ring 1 is evenly drilled with seat ring installation holes 4 distributed in a ring and passing through the upper and lower end surfaces of the seat ring 1 .

[0012] Two upper raceways are formed between the upper shaft ring 2 and the seat ring 1, two lower raceways are formed between the lower shaft ring 3 and the seat ring 1, the side of the seat ring 1 is connected to the outer surfaces of the upper shaft ring 2 and the lower shaft ring 3 A side raceway is formed between them; cylindrical rolling elements are placed in the upper, lower and side raceways.

[0013] It also includes the lower main channel 5, the lower branch channel, the upper main channel 7 and the upper branch channel. The upper main channel 7 and the lower main channel 5 are horizontal channels with the same inner diameter.

[0014] Wherein, the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com