A wet dual clutch

A wet dual clutch and clutch technology, applied in clutches, fluid drive clutches, non-mechanical drive clutches, etc., can solve the problems of complex annular oil channel design, high cost, complex structure, etc., and achieve enhanced stability, high efficiency, fast speed The effect of switching and evenly supplying oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

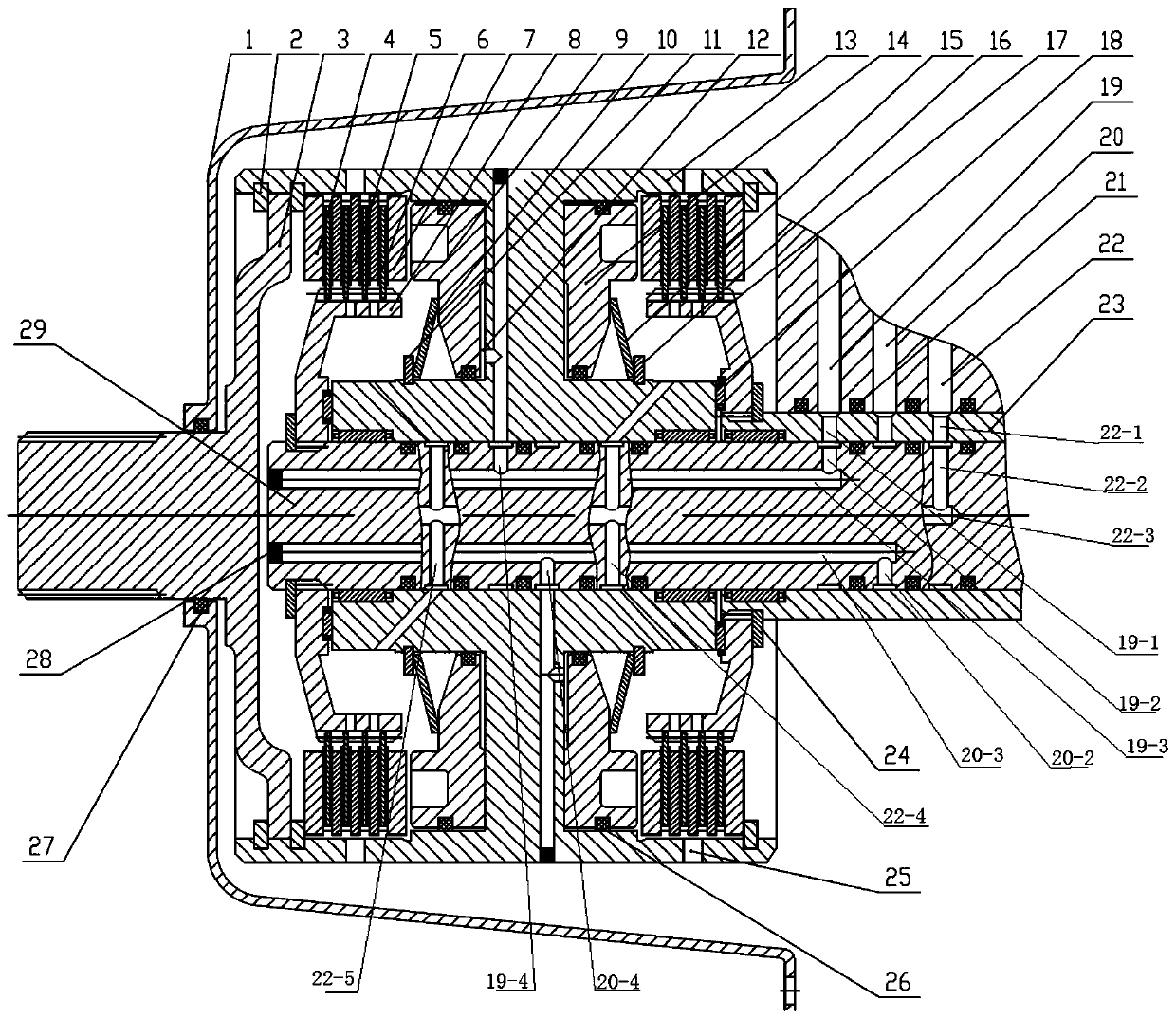

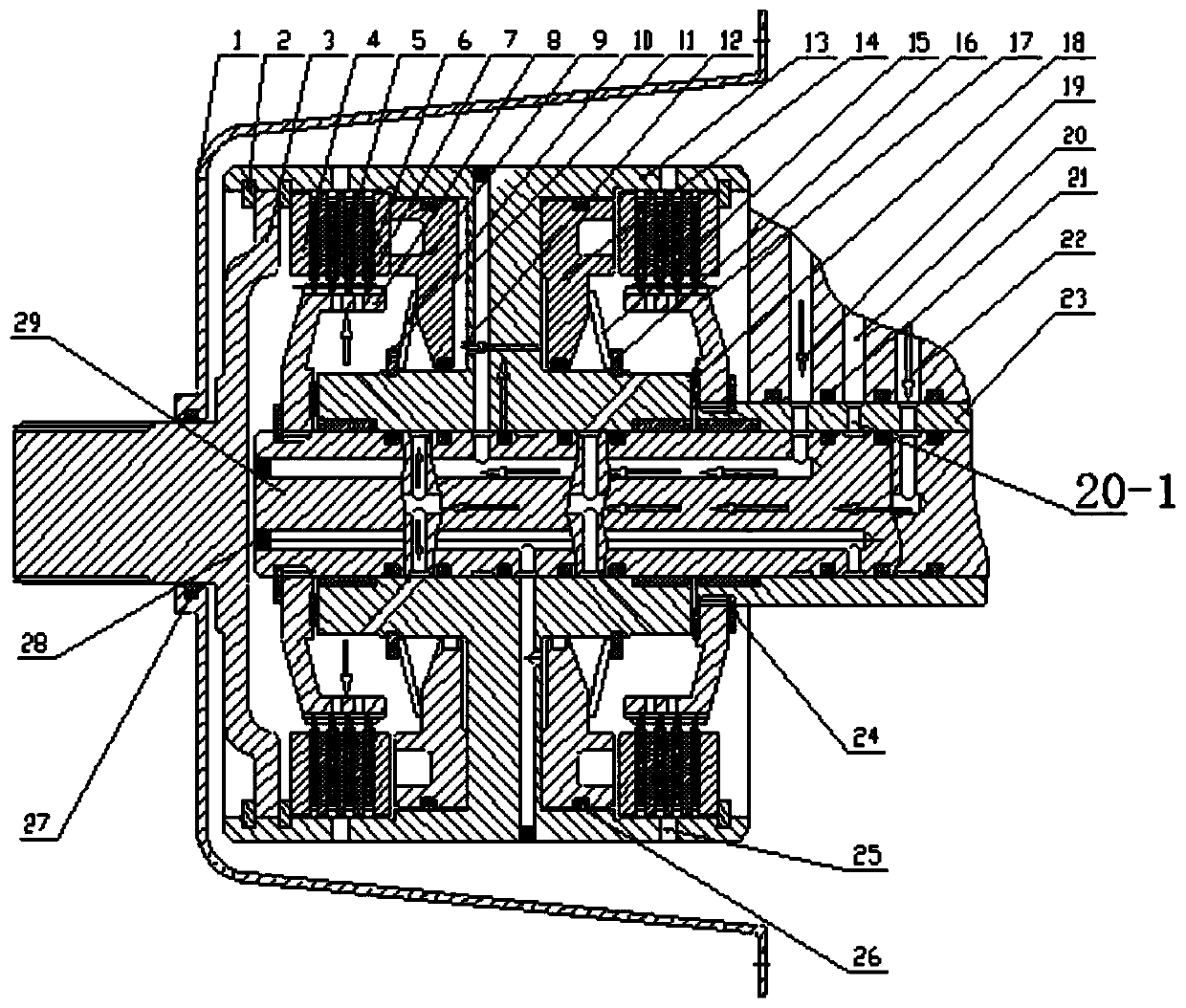

[0028] Such as figure 1 As shown, a kind of wet dual clutch of the present invention comprises left clutch control oil passage 19, right clutch control oil passage 20 and lubricating oil passage 22, clutch input plate 3, clutch sealing cover 1, clutch outer wheel hub 13, setting In the clutch outer hub 13 the same left clutch unit comprising the left clutch output hub 8 and the left clutch output shaft 29 and the right clutch unit comprising the right clutch output hub 17 and the right clutch output shaft 23, The right clutch output shaft 23 is a shaft sleeve shape, and one end of the left clutch output shaft 29 is installed in the right output shaft 23 through multiple groups of thrust needle bearings 18, and a piston sealing ring 26 is arranged between the two, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com